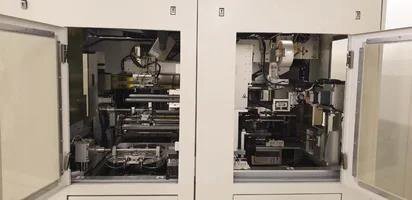

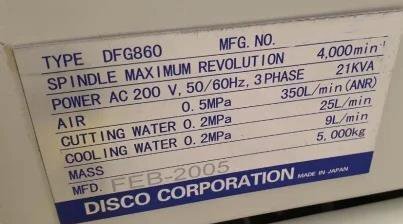

Used DISCO DFG 860 #9355526 for sale

URL successfully copied!

Tap to zoom

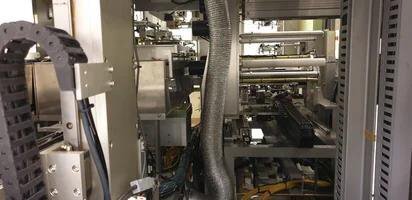

DISCO DFG 860 is an advanced wafer grinding, lapping, and polishing equipment designed for machining small components in the semiconductor, research and development, and optics industries. This system has a highly efficient planetary grinding unit with four working stations. It can simultaneously polish or grind up to four wafers at the same time and will save significant time compared to traditional grinding or polishing systems. Additionally, DISCO DFG860 unit doubles as a lapping machine due to the inclusion of a centralized filtered and cooled slurry machine. DFG 860 tool has automated wafer mapping capability, giving users the ability to feed in wafer position data and create different grinding patterns for each wafer or substrate. This asset also allows for the set-up of multiple grinding processes that are user-defined and custom tailored for specific applications. This ensures that users have control over the size and shape of their final product, resulting in precise and consistent performance over long production cycles. DFG860 model features a conveying equipment that holds up to four 300mm wafers and has an adjustable center guide providing a large range for wafer loading; using vertical vibration technology, the wafers are transported between grinding, lapping, and polishing stations. With a grinding speed of up to 3500 rpm being achievable, DISCO DFG 860 is designed for high-performance grinding of wafers up to 12" in size. The polishing station on DISCO DFG860 features a low-vibration, balanced polishing cloth bearing unit that enables smooth and optimal surface conditioning with low polishing forces. By using customized, pre-programmed stroking patterns users can easily achieve even polishing of their wafer's surface. DFG 860 system also automatically removes slurry residue from polishing heads, providing the best surface cleaning and adhesion for critical applications. DFG860 is a powerful unit designed with an intuitive user interface, allowing for a setup in just minutes. This machine also includes a range of options including multiple sizes of polishing pads, single-wafer and batch processing abilities, and CAN bus for expanded connectivity options. This tool is the ideal platform for grinding, lapping, and polishing of wafers and substrates, used heavily in the semiconductor industry as well as research and development.

There are no reviews yet