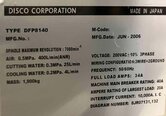

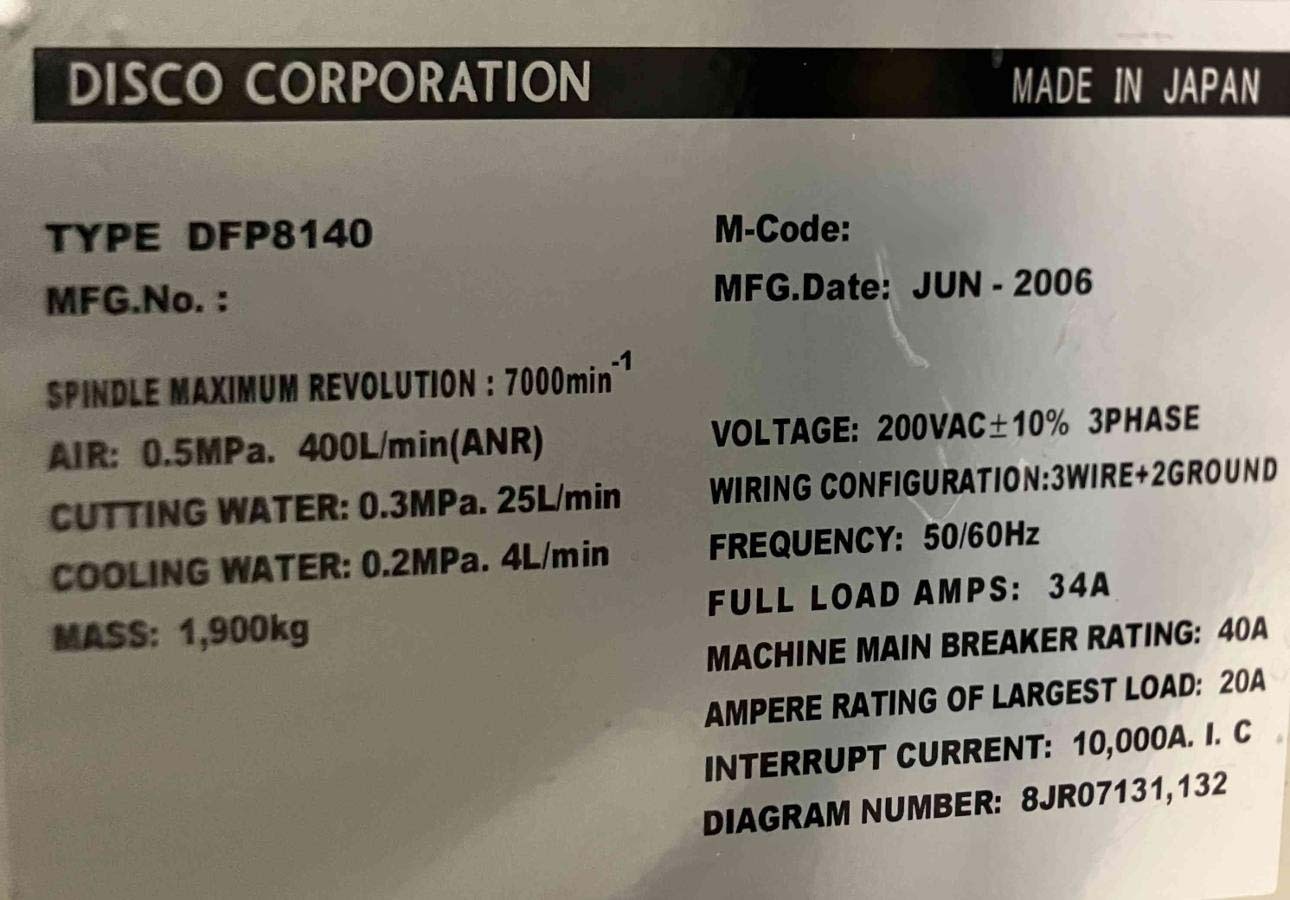

Used DISCO DFP 8140 #293656031 for sale

URL successfully copied!

Tap to zoom

ID: 293656031

Wafer Size: 6"-8"

Vintage: 2006

Wafer polisher, 6"-8"

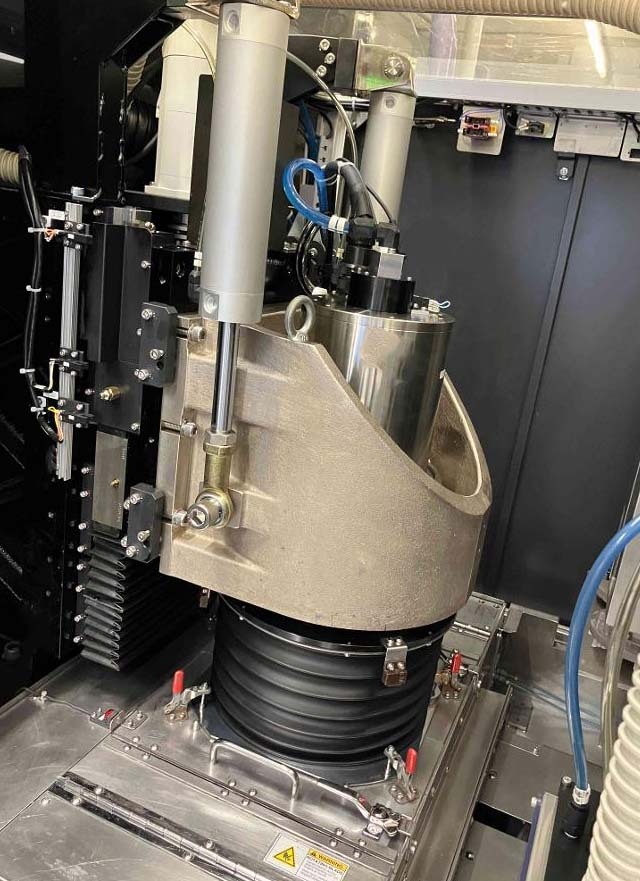

TAIKO Spindle

2006 vintage.

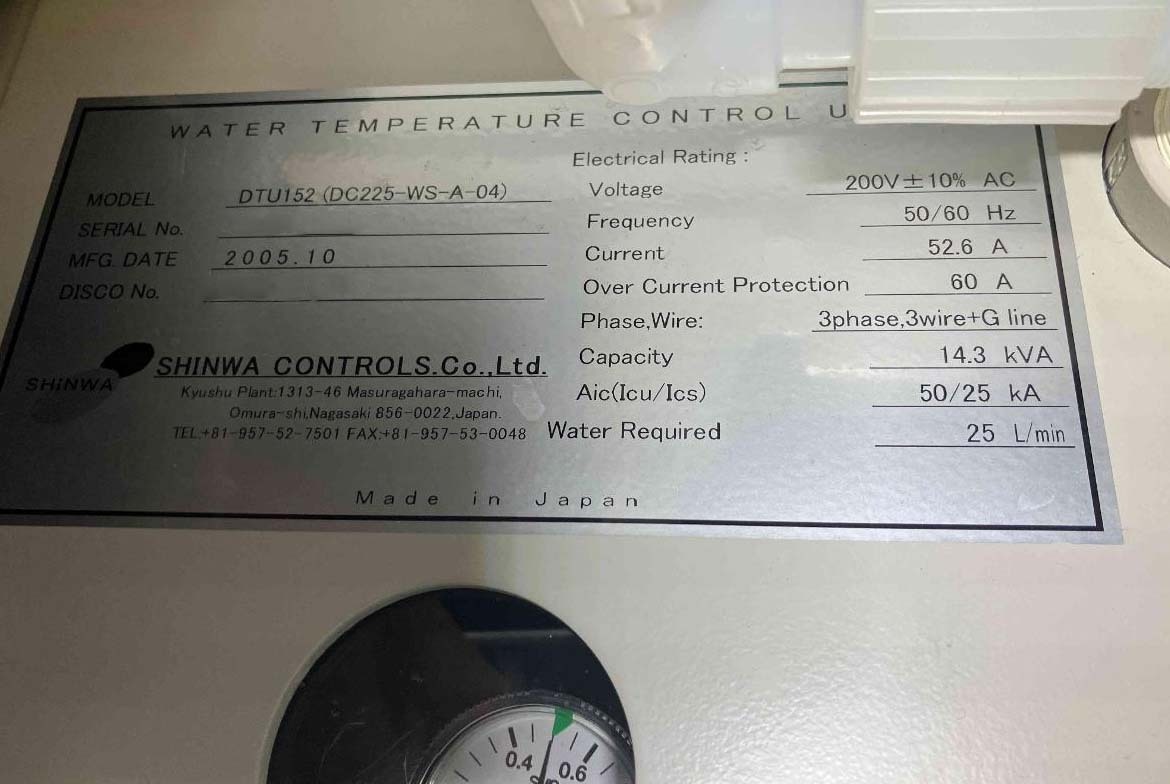

DISCO DFP 8140 is a fully automated wafer grinding, lapping and polishing equipment designed for high precision polishing of semiconductor wafers. This system is capable of processing wafers up to 8 inches in diameter and is equipped with 4 grinding/polishing stations which include a wafer grind station, wafer lapping station, coarse diamond polishing station and a fine diamond polishing station. DISCO DFP8140 is especially suited for the grinding, lapping and polishing of planar and non-planar semiconductor wafers. The grinding station of the machine is equipped with two grinding/polishing tapes which allows for efficient grinding/polishing of wafers. The wafer lapping station is capable of handling wafers with a diameter up to 8" and can lapp wafers with a high surface finish. The coarse diamond polishing station is designed to provide a correct pre-polish of large planar and non-planar semiconductor wafers. It is capable of precision polishing of up to 3μm RMS (root mean square) roughness and has a maximum force control unit to ensure optimum surface quality and repeatability. The fine diamond polishing station is used for finishing polishing wafers to a high quality surface finish. It has a special suspension machine which ensures stability and prevents vibration during polishing. In addition to its grinding, lapping and polishing capabilities, DFP 8140 also has other features which make it a very attractive tool for processing semiconductor wafers. These include a contamination prevention asset which prevents foreign material from entering the chamber, an optical inspection model to inspect the surface of the wafers during grinding/polishing, an automatic wafer loader which enables the machine to load up to two kinds of wafers, and a recipe management equipment which allows for easy programming and recall of processing conditions for large volume production. DFP8140 is suitable for a wide range of wafer related processes, such as lapping, planarization, non-planarization and CMP (chemical mechanical polishing). Its robust, accurate and repeatable design allows the machine to provide a consistent surface finish on a variety of wafer materials and can be used in the production of semiconductor devices, solar and laser applications. DISCO DFP 8140 provides a highly efficient and cost effective process for grinding, lapping and polishing of semiconductor wafers and is an integral part of any semiconductor manufacturing system.

There are no reviews yet