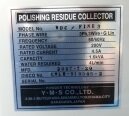

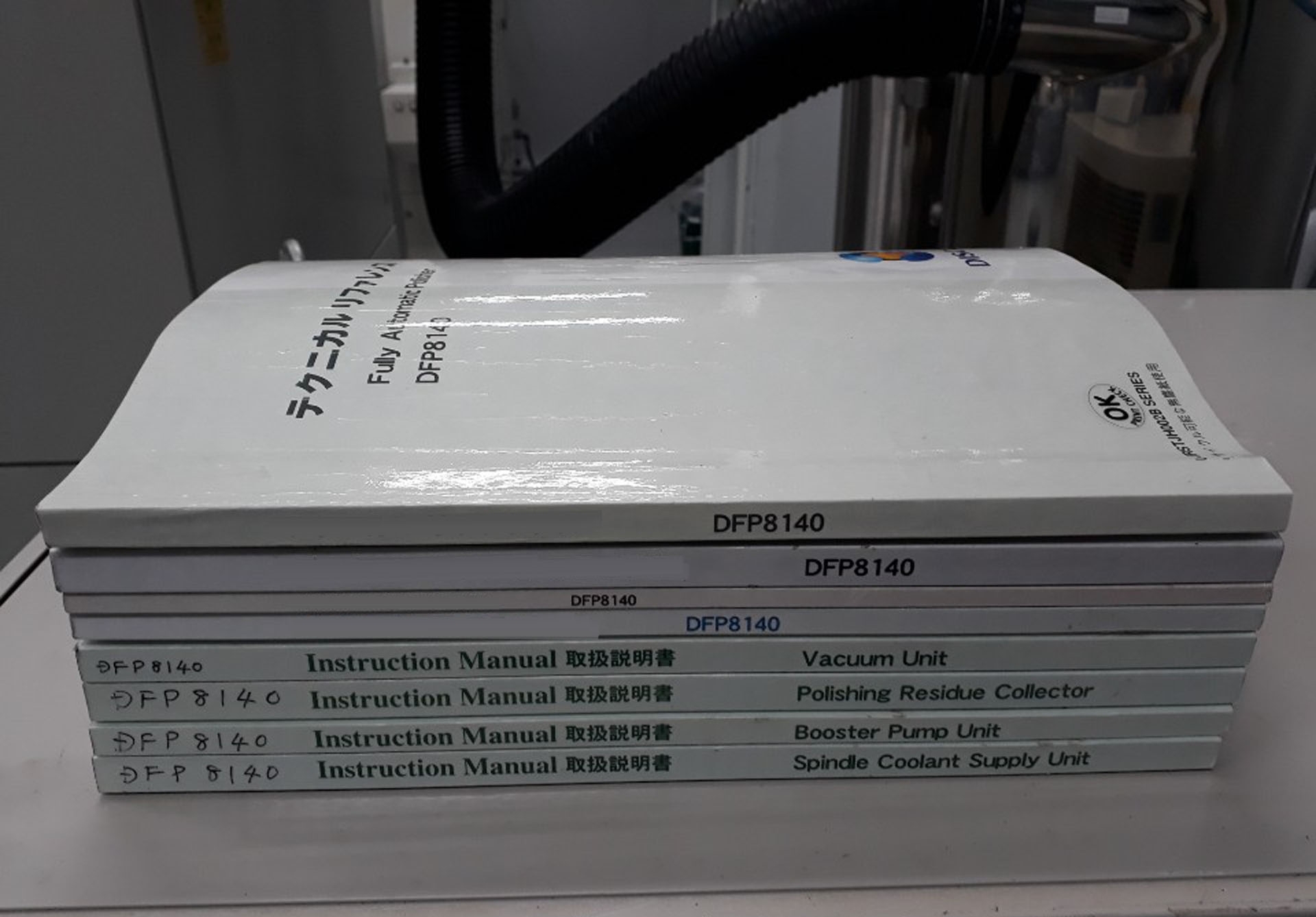

Used DISCO DFP 8140 #9211320 for sale

URL successfully copied!

Tap to zoom

ID: 9211320

Wafer Size: 8"

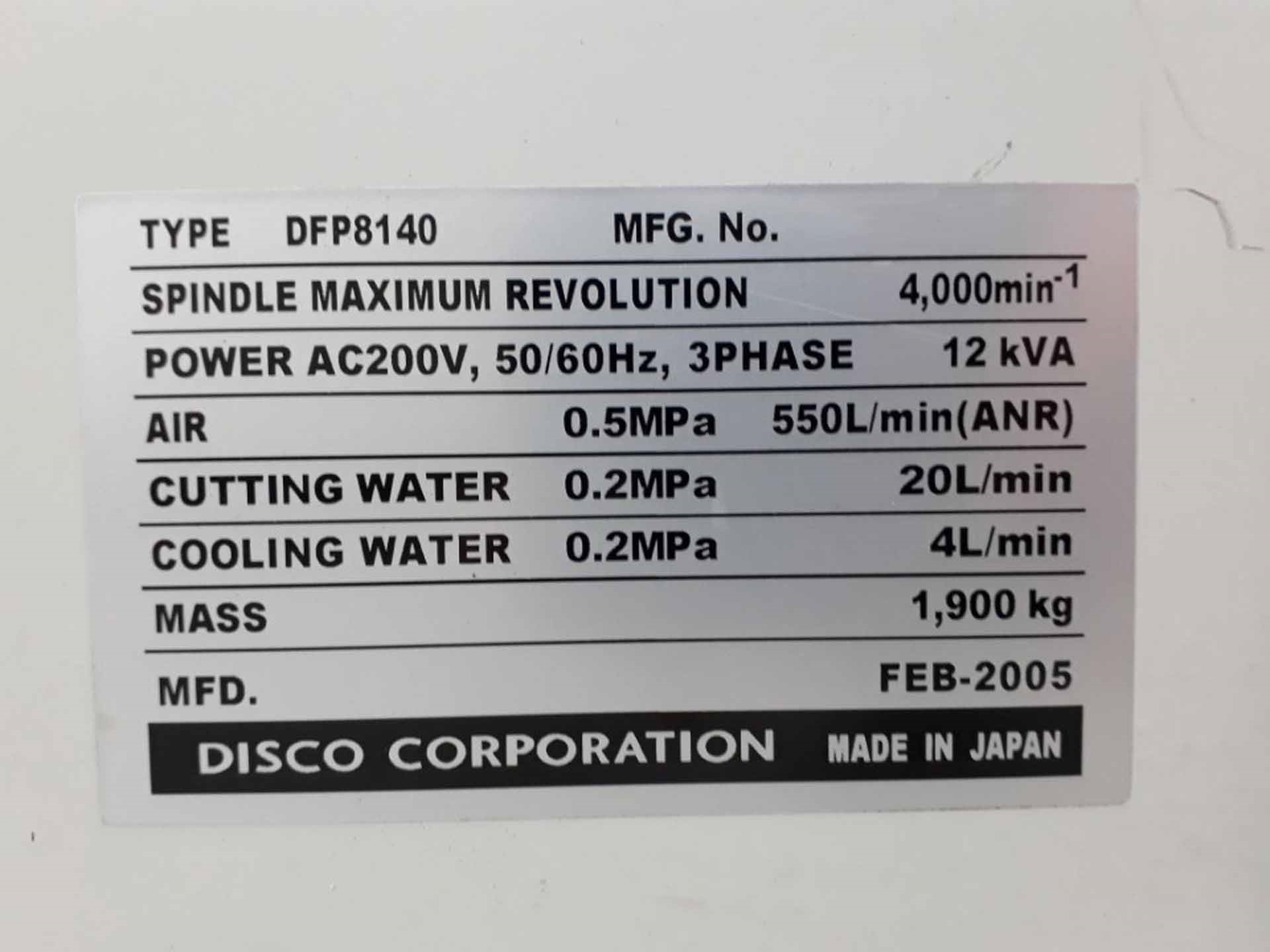

Vintage: 2005

Polisher, 8"

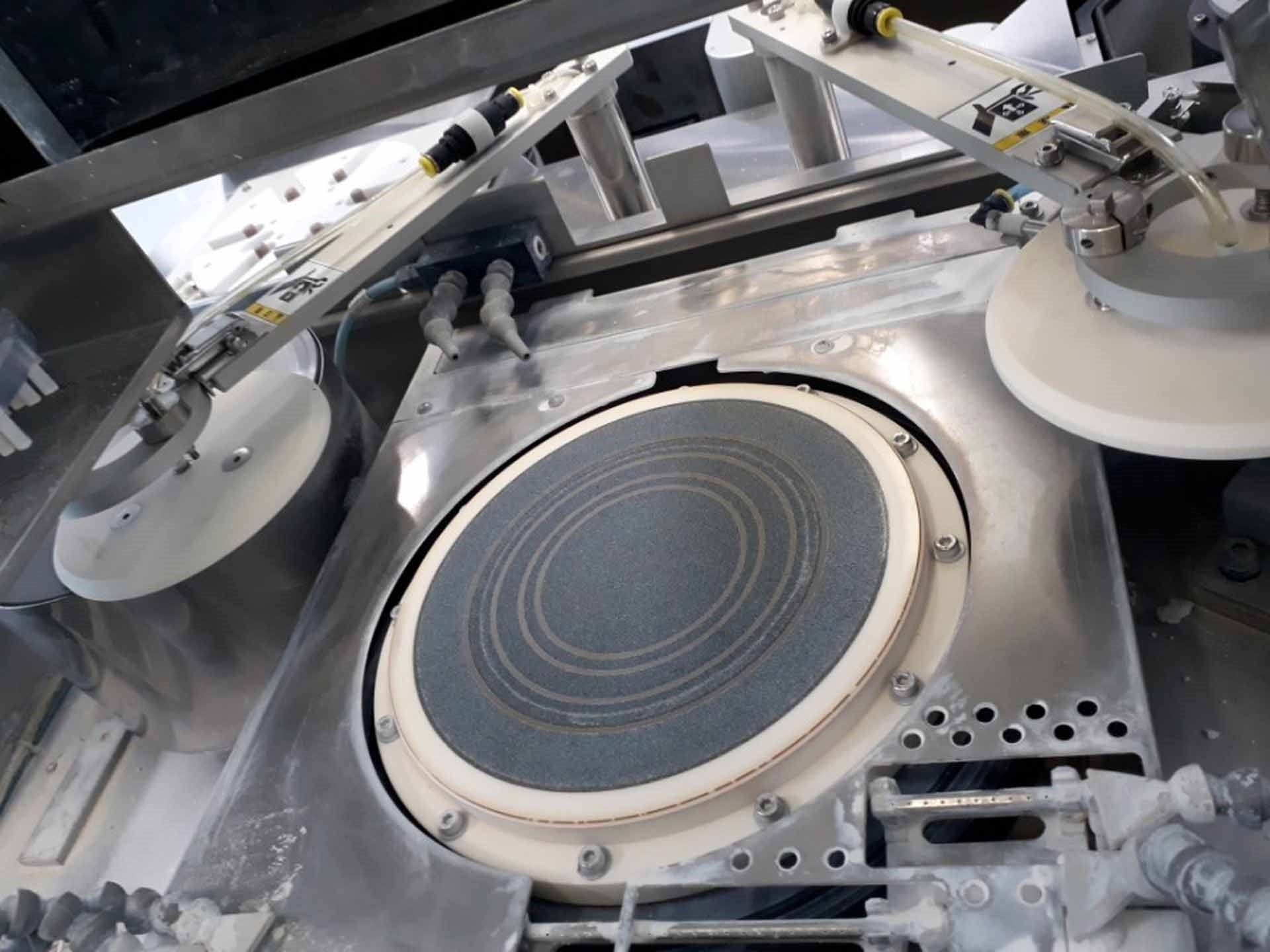

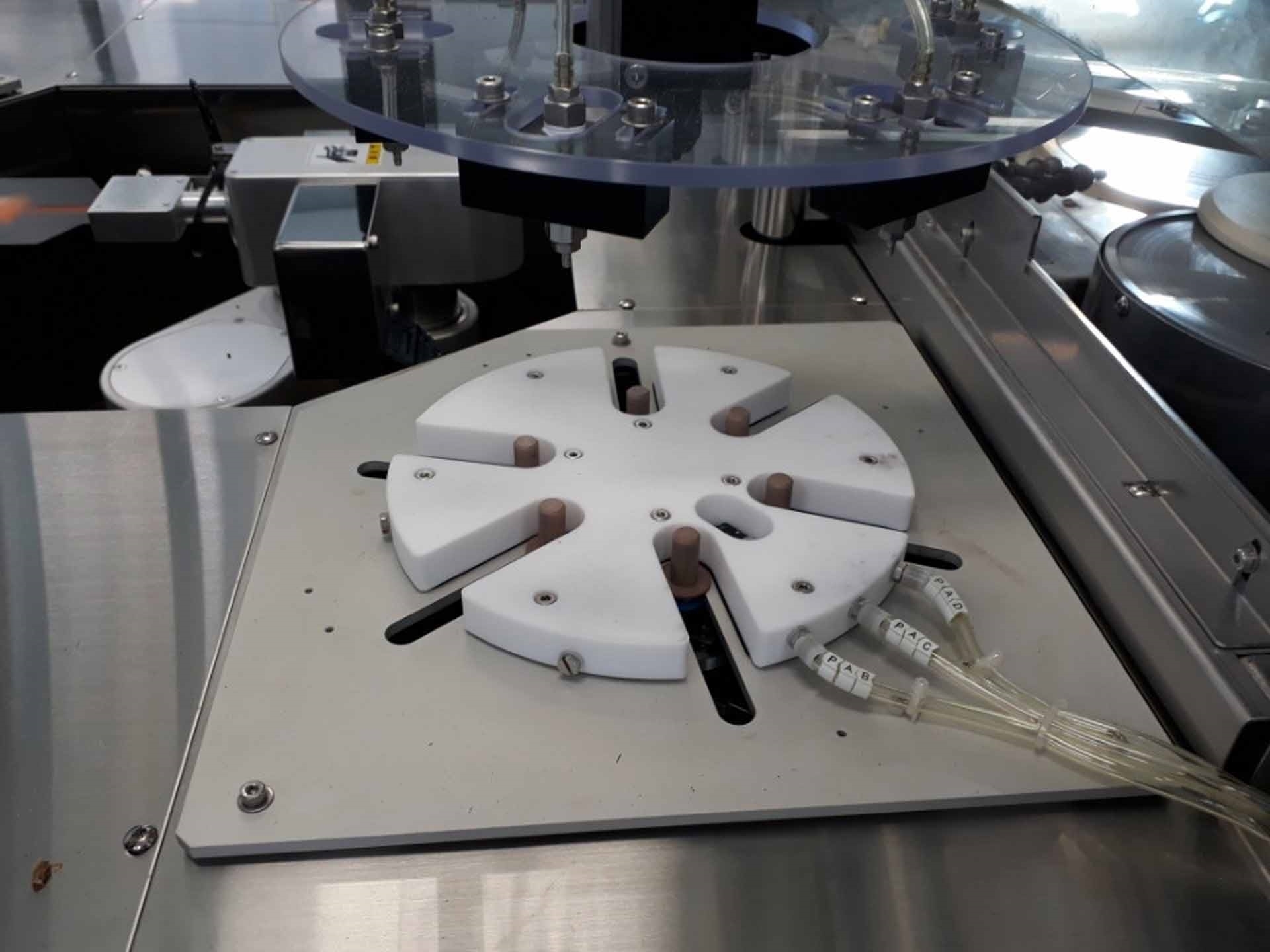

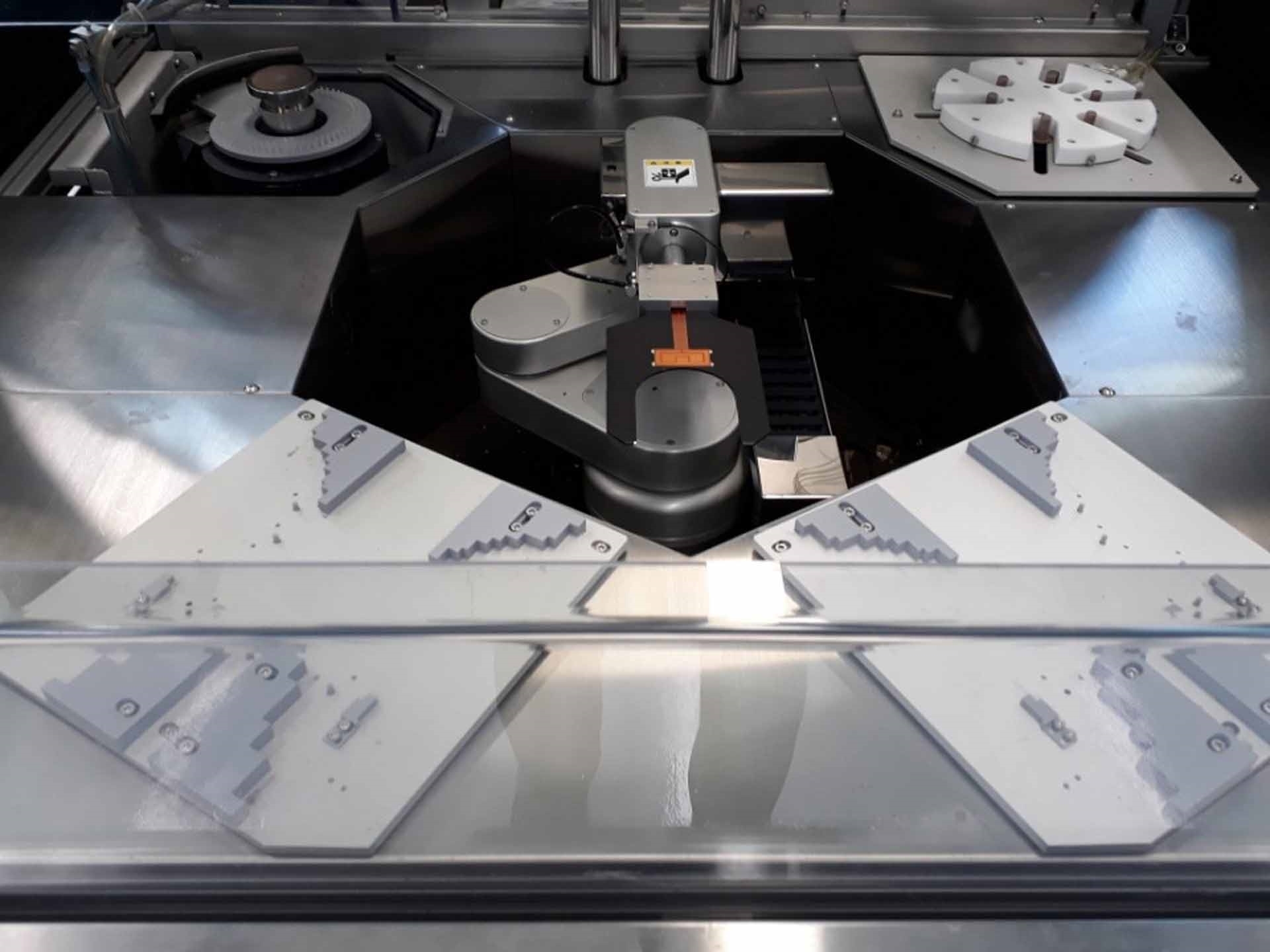

Polishing method: Anomalous in-feed grinding with wafer rotation

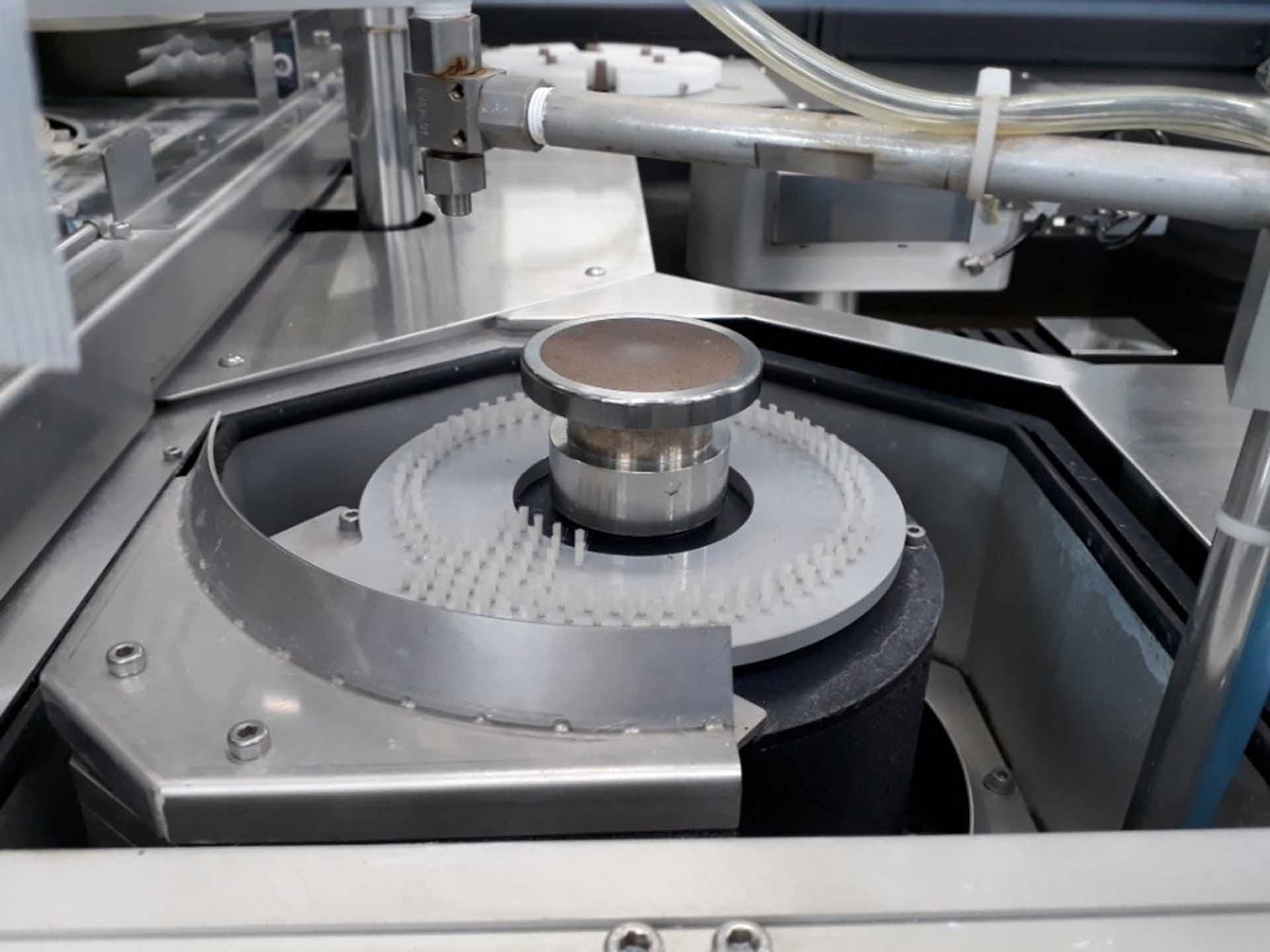

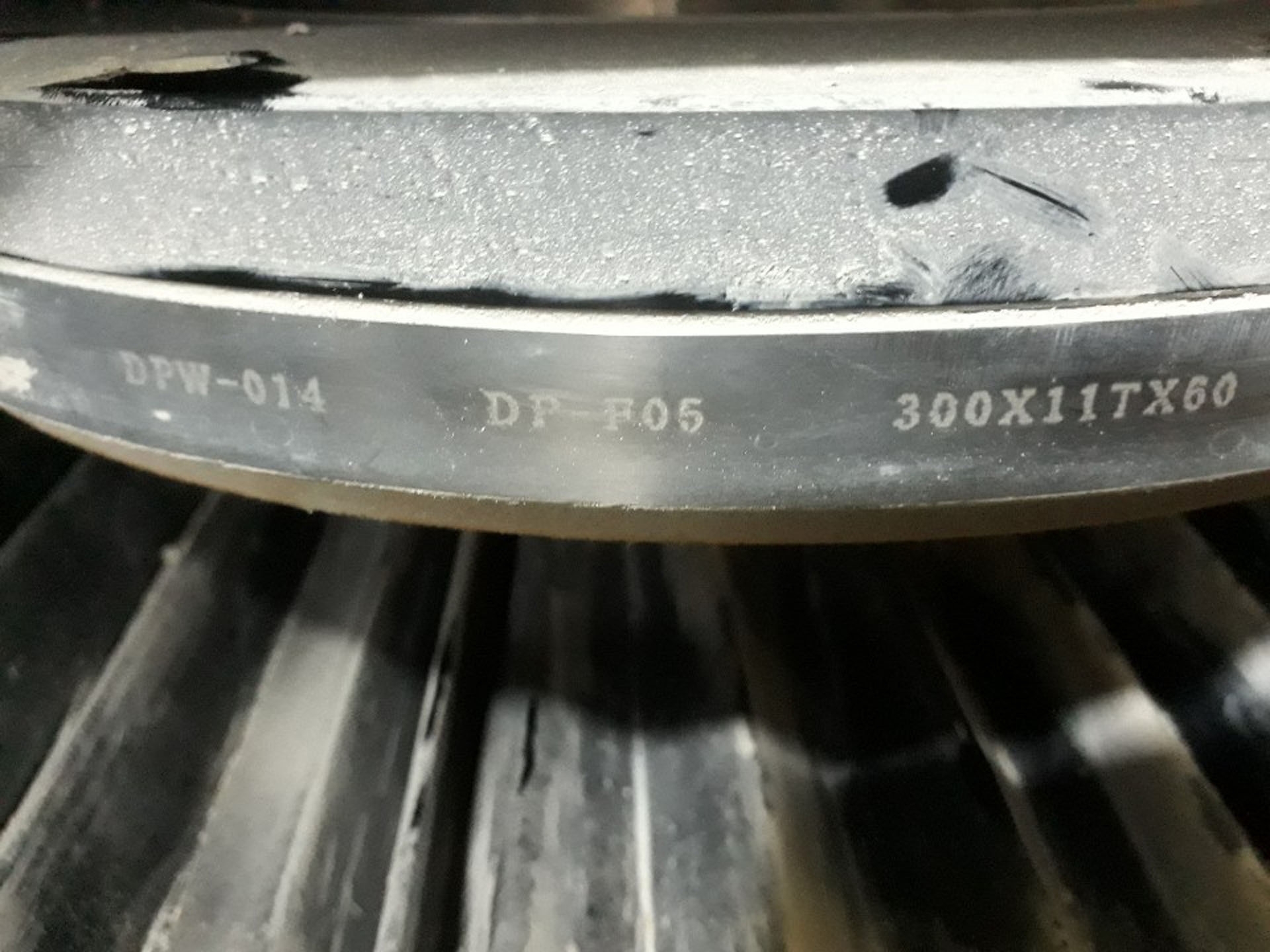

Dry polishing wheel: φ300 mm

Chuck table type: Porous chuck table

Chuck-method: Vacuum

Revolution: 0-300 min^-1

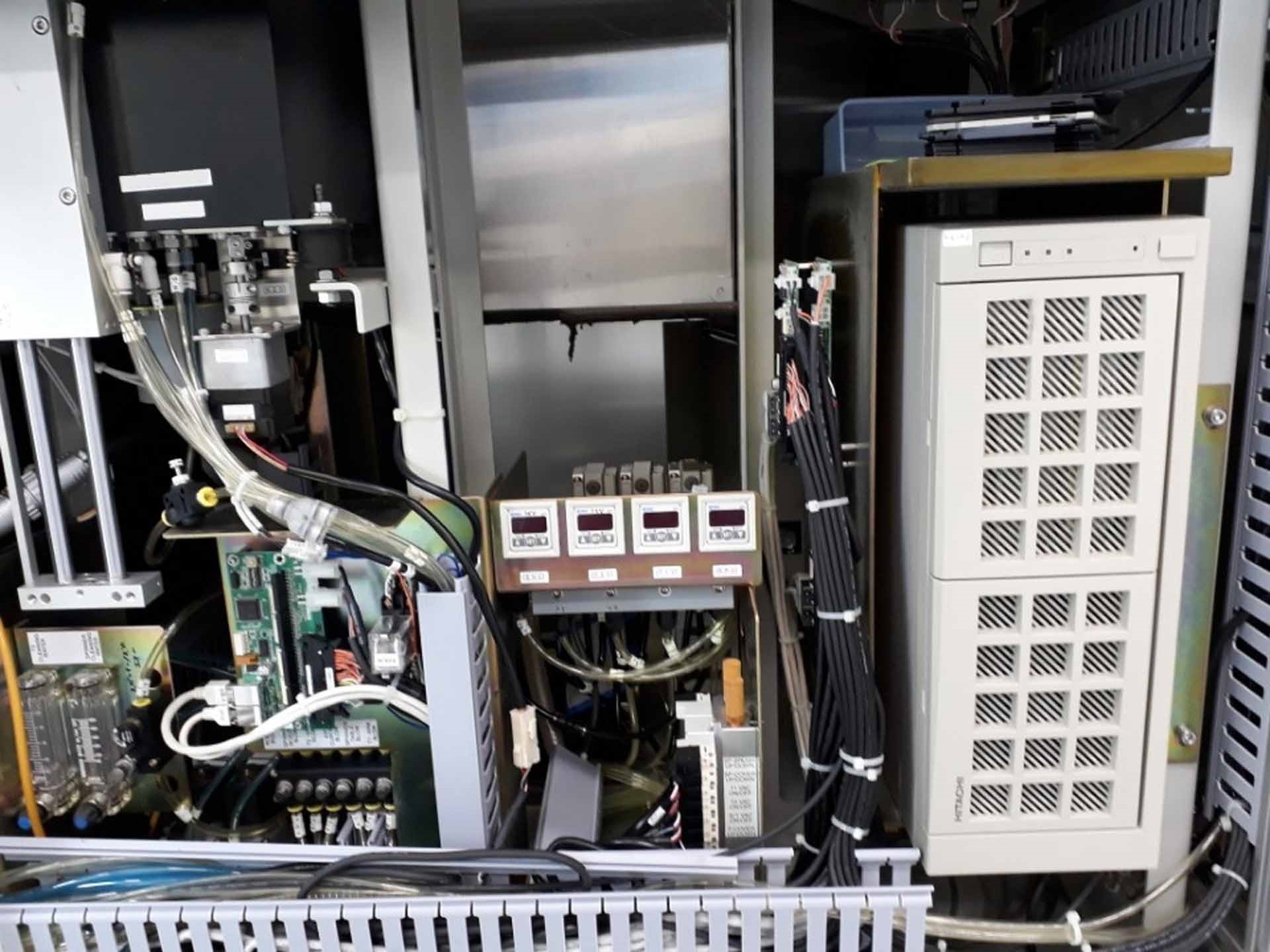

Operating system: Windows NT 4.0

Chuck table cleaning:

Water and air thrust up

Leveling stone

Brush cleaning

Spindle:

Output: 4.8 kW

Revolution speed range: 1,000 - 4,000 min^-1

Internal load sensor: Thin force sensor

Spinner unit:

2-Stream jet nozzle cleaning

Both side drying

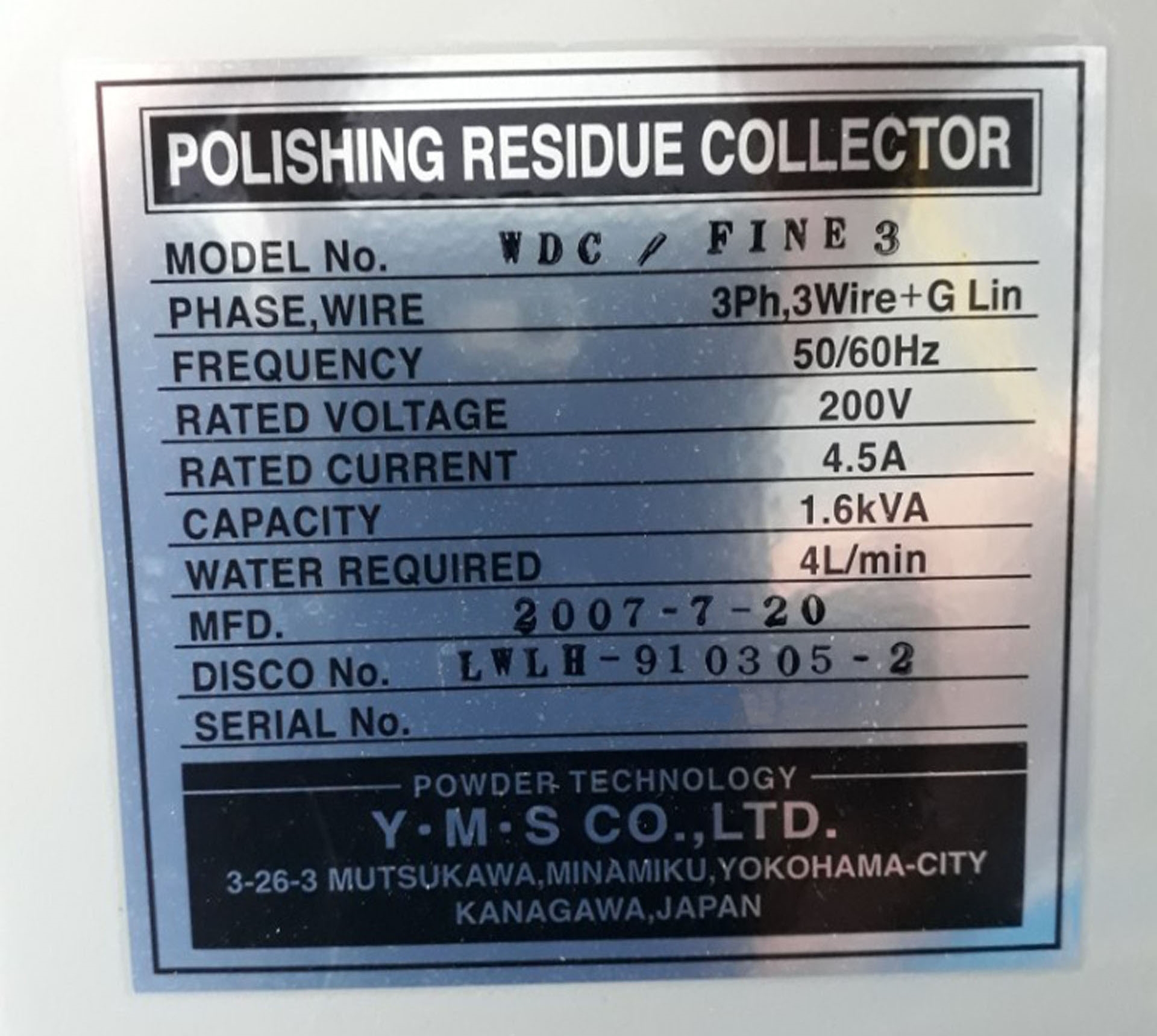

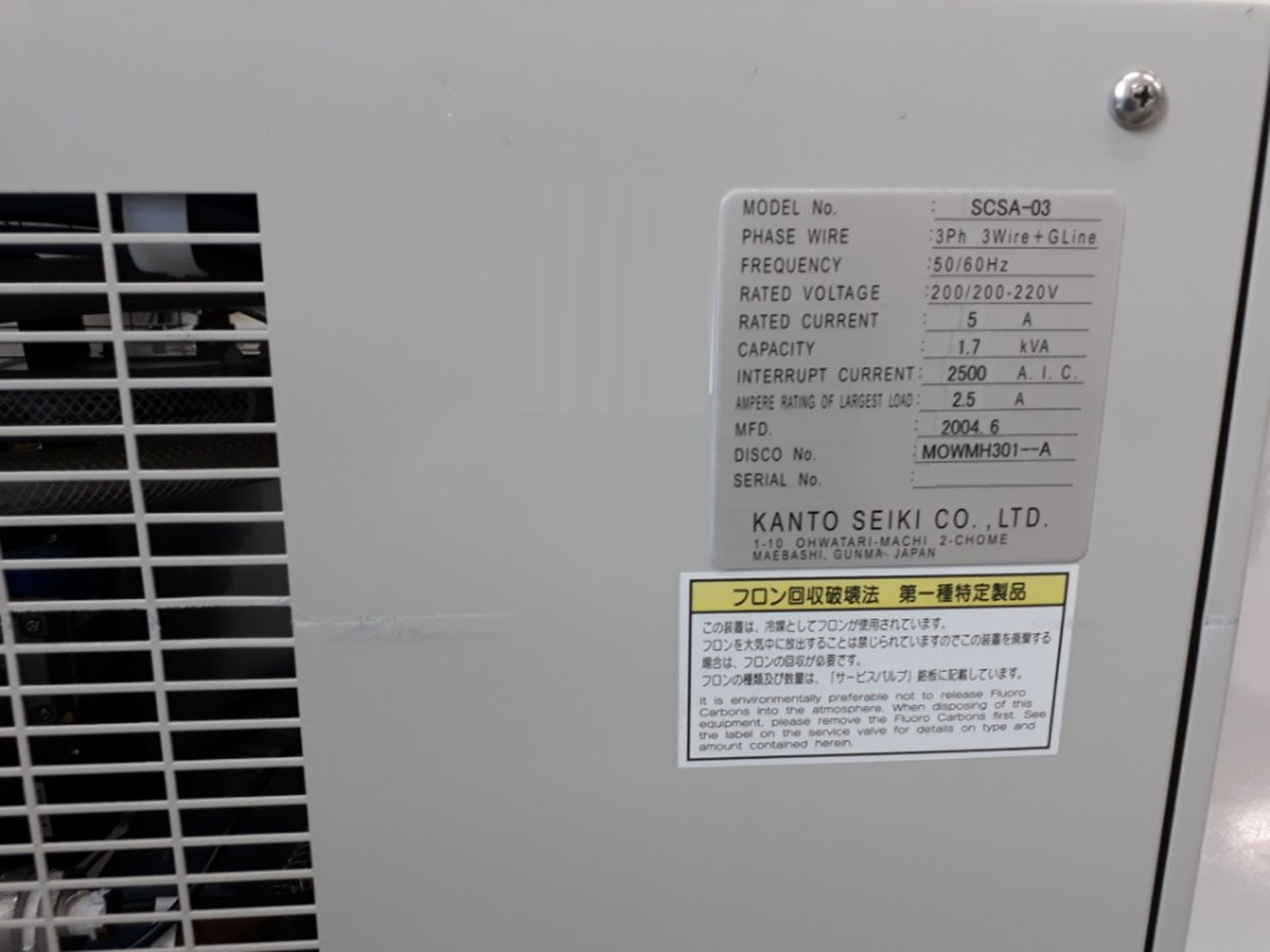

Power supply

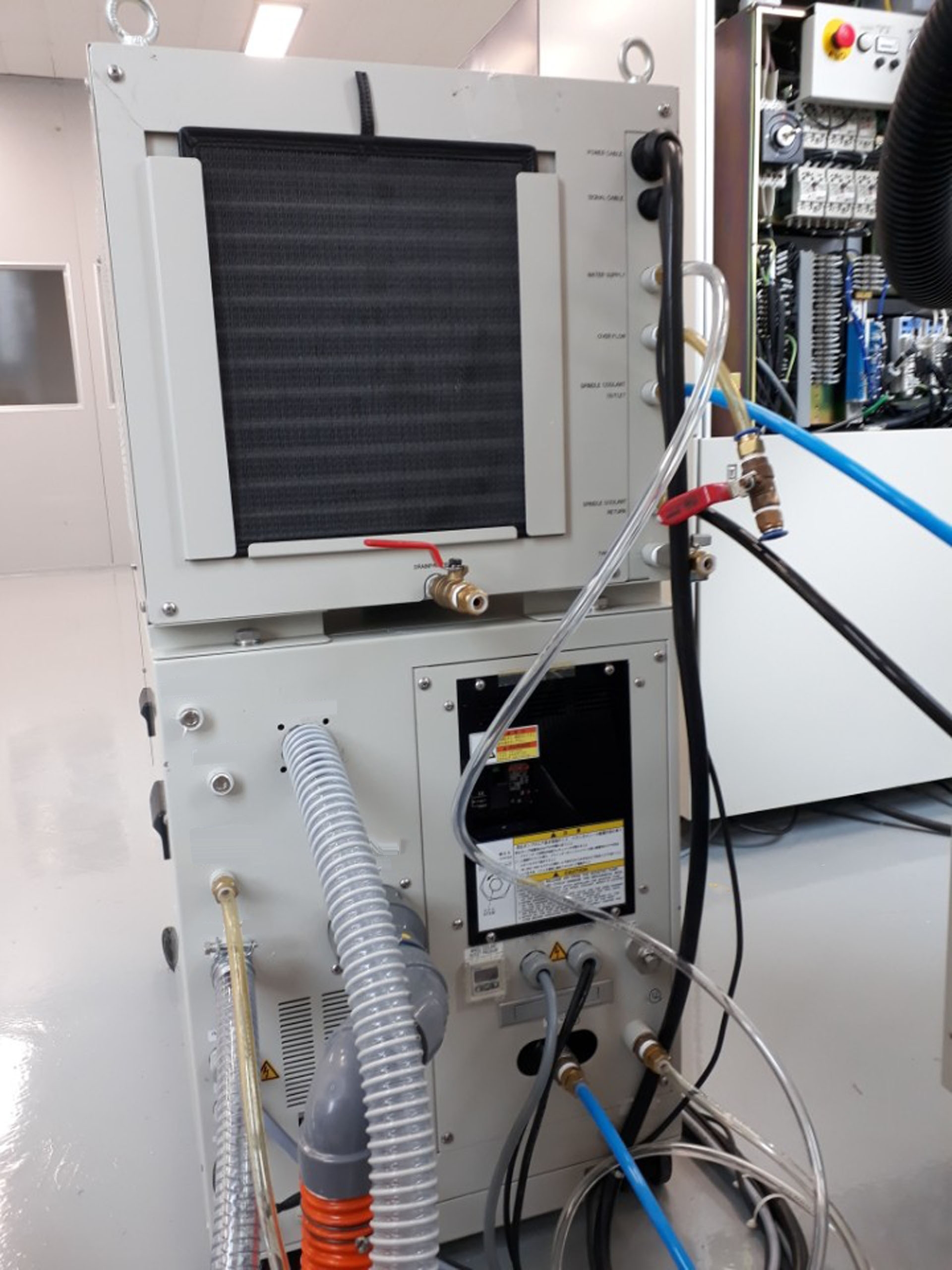

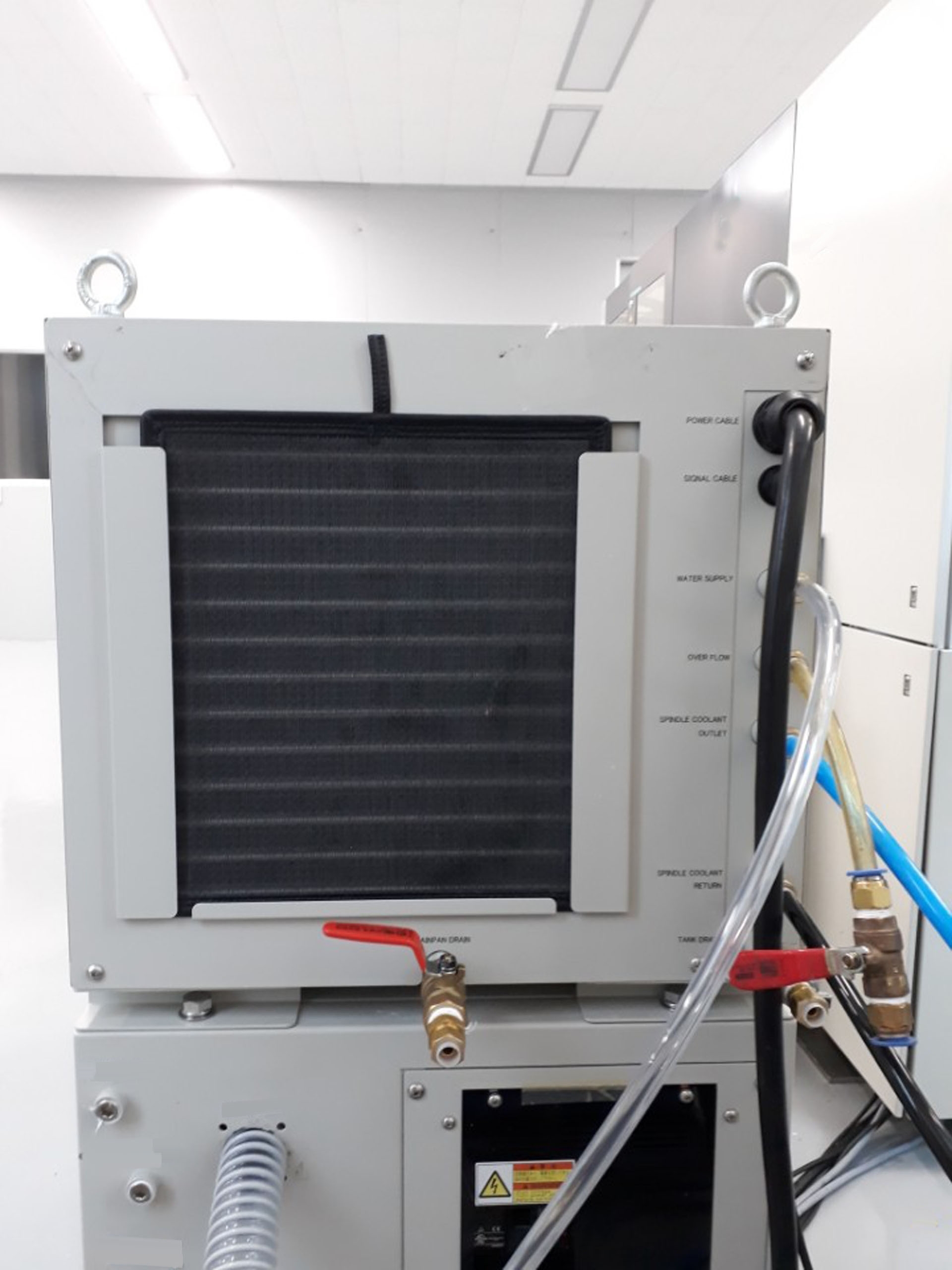

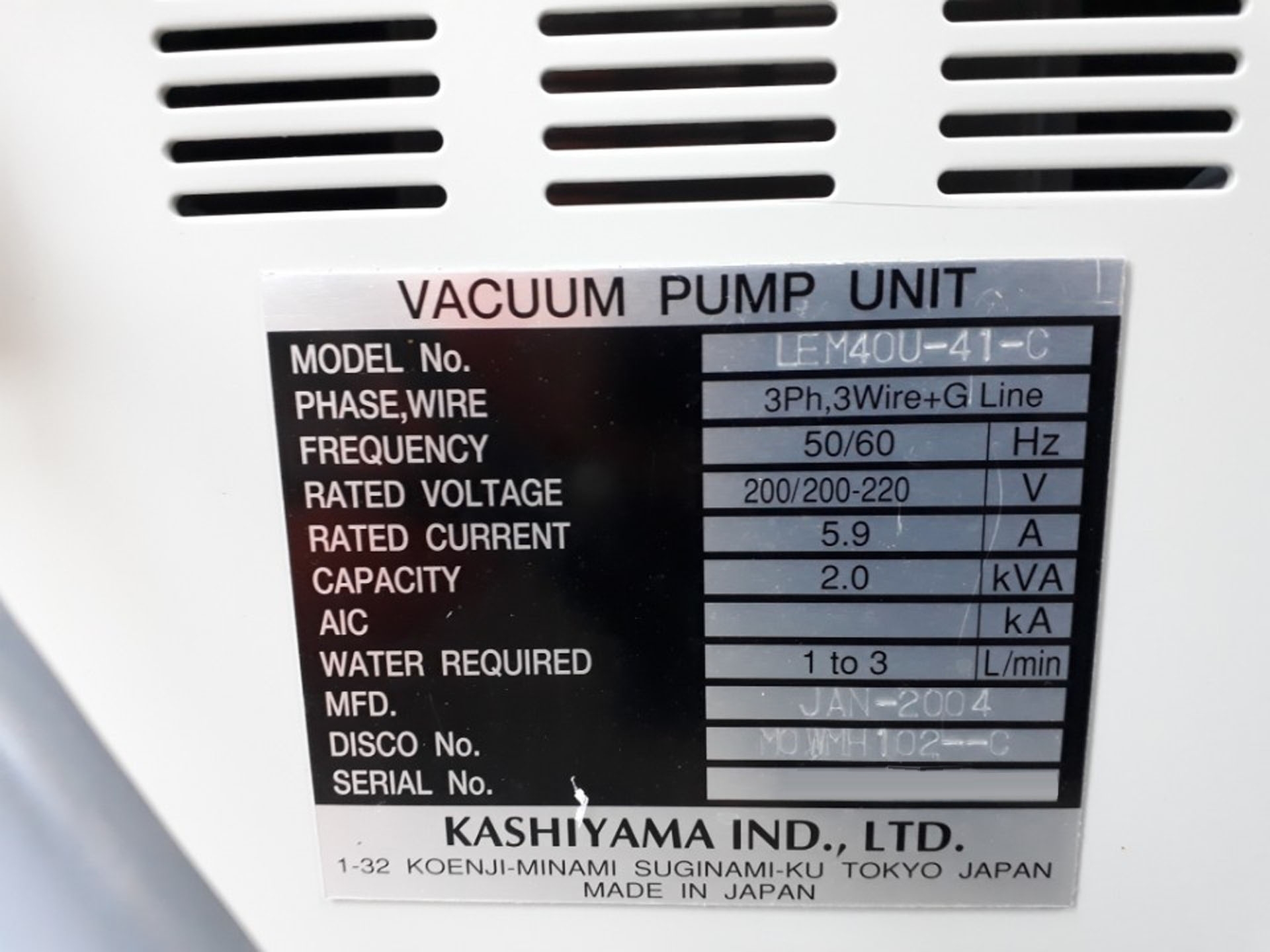

Chiller / Vacuum unit

Air: 0.5 MPA, 550 L/min (ANR)

Cutting water: 0.2 MPA, 20 L/min

Cooling water: 0.2 MPA, 4 L/min

Power supply: AC 200 V, 50/60 Hz, 3 Phase, 12 kVA

2005 vintage.

DISCO DFP 8140 is an advanced wafer grinding, lapping and polishing equipment designed for high throughput and superior results in today's most advanced semiconductor wafer manufacturing processes. Developed by DISCO Hi-Tec, DISCO DFP8140 offers high accuracy, superior results, and high throughput with superior level of control capabilities. This new polishing system features the latest in advanced grinding and lapping techniques, optimized for automated operation for silicon wafers and other substrates. DFP 8140 is an ideal unit for backgrinding, CMP planarization, lapping, and surface polishing. It is suitable for silicon, quartz, and glass substrates. It includes a variety of tools and accessories such as an oxidizer and 8-inch diameter diamond polishing pads, as well as other tools to lay a foundation for superior results. The machine is programmed with a graphical control machine which enables the user to input and save unique processes, as well as record detailed process data. The tool also offers advanced safety features such as interlock protection and alarms, allowing for better process control and operation. DFP8140 features a high speed 8" polishing spindle that rotates up to 16000 RPM. This ensures a high polishing speed and can accommodate both flat and complex shapes, with a smooth finish. The grinding spindle can be used for manual or automatic operation to simplify the grinding process. For lapping and planarization, DISCO DFP 8140 has an adjustable pressure head which can be modified to provide superior control over the polishing rate. In addition, the asset has an integrated vacuum polishing model for flawless polishing results. DISCO DFP8140 is an advanced equipment designed for wafer grinding, lapping and polishing. With its efficient processes and superior quality results, it is suitable for a wide range of semiconductor processes, such as backgrinding, CMP planarization, lapping, and surface polishing. Featuring a high-speed 8-inch polishing spindle, adjustable pressure head, integrated vacuum polishing system and advanced control unit, DFP 8140 is the perfect choice for cost-effective and superior results.

There are no reviews yet