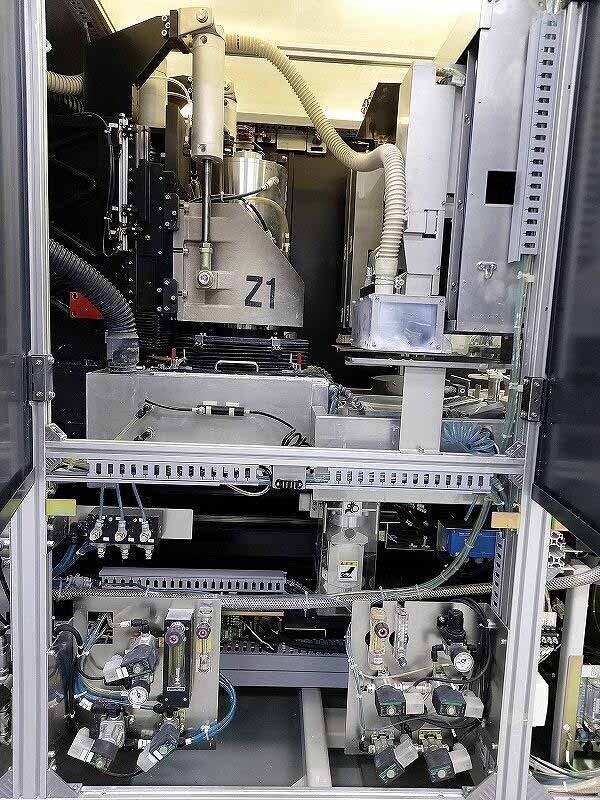

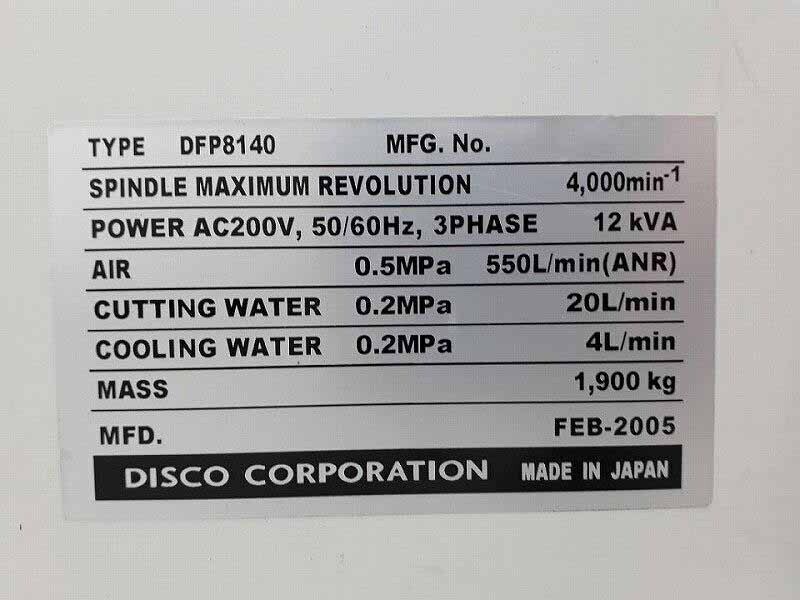

Used DISCO DFP 8140 #9351879 for sale

URL successfully copied!

Tap to zoom

ID: 9351879

Vintage: 2005

Wafer polisher

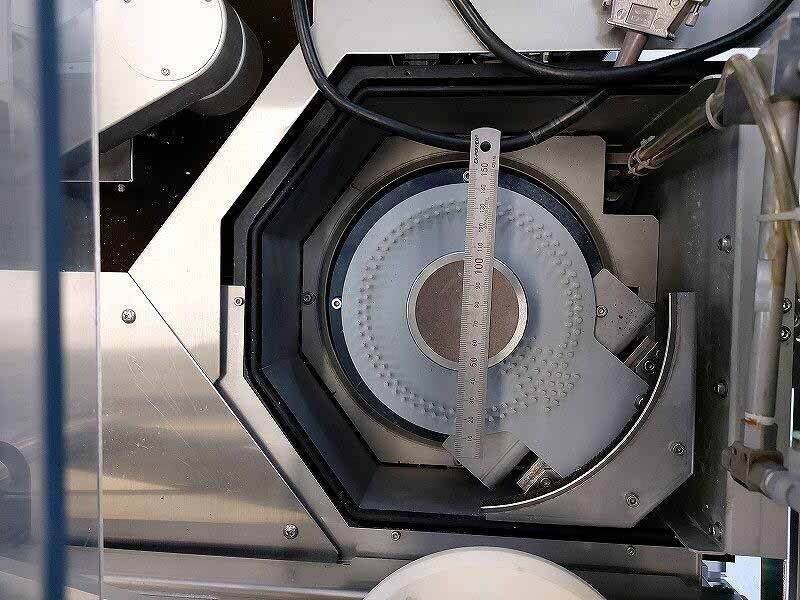

Wafer diameter: 4"-8"

Polishing method: Anomalous in-feed grinding with wafer rotation

Dry polishing wheel: 300 mm

Porous chuck table

Revolutions: 0-300 min^-1

Vacuum chuck

Chuck table cleaning:

Water and air thrust up

Leveling stone

Brush cleaning

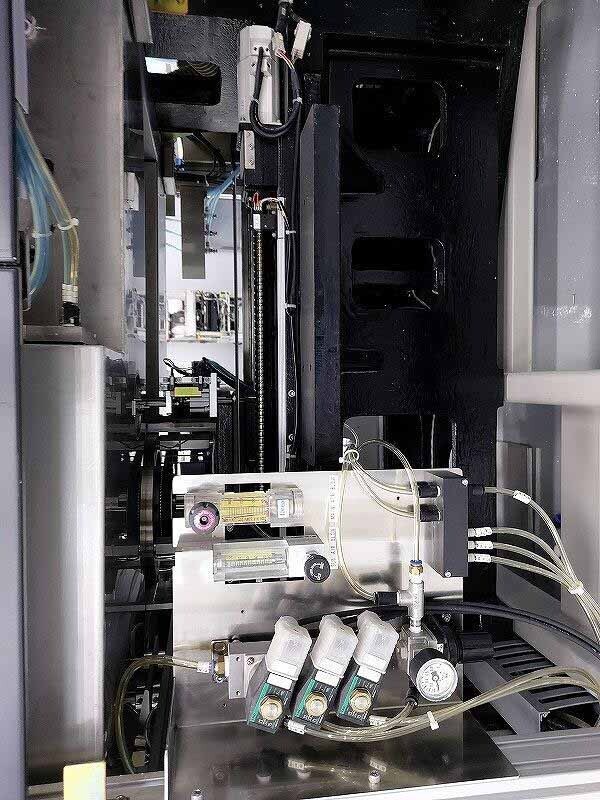

Spinner unit:

2-Stream jet nozzle cleaning

Both side drying

Internal load sensor: Thin force sensor

Spindle:

Output: 4.8 kW

Revolution speed range: 1000-4000 min^-1

2005 vintage.

DISCO DFP 8140 is a wafer grinding, lapping and polishing equipment that delivers high precision and superior surface finish for a variety of wafer products. The system is comprised of a large-scale grinding and polishing tool, the SPG-8140, as well as several additional components that are necessary for its operation, such as a spin chuck, abrasive material, and an air bearing force control unit. The SPG-8140 is a large-scale precision tool that features a 7.8" (195 mm) table travel, 6" (150 mm) grinding/polishing disk, and 7.9" (200 mm) wafer chuck. The SPG-8140 features water-cooled grinding/polishing plate and uses high-precision digital control technology to ensure precise control of abrasive surface finish. The unit also features a self-diagnostic machine to allow real-time inspection for both grinding and polishing. The air bearing force control unit is also included, allowing for force control during the grinding/polishing process. The spin-chuck can be adjusted from a 0 to 400 rpm, allowing for grinding and lapping applications and an increased grinding speed. In addition, the tool includes a 9" (225mm) wafer transfer arm, which can be used to transfer wafers to and from the chuck. In addition to its grinding and polishing capabilities, DISCO DFP8140 also features a in-situ polishing capability. This feature allows for a low-contact polishing of thin-films and low-k surfaces, allowing greater control over the surface finish and polishing quality. The asset also includes a software package that simplifies the operation and operation of the model. Overall, DFP 8140 is a high-precision grinding, lapping and polishing equipment, capable of delivering superior surface finish and accuracy for a range of wafer products. The system is simple to operate and maintain, featuring an intuitive software package for operation and real-time diagnostic features for monitoring of the process. The unit is highly suitable for grinding and polishing operations, as well as low-contact polishing of specialized thin-film and low-k surfaces.

There are no reviews yet