Used DISCO DGP 8761 #293663154 for sale

URL successfully copied!

Tap to zoom

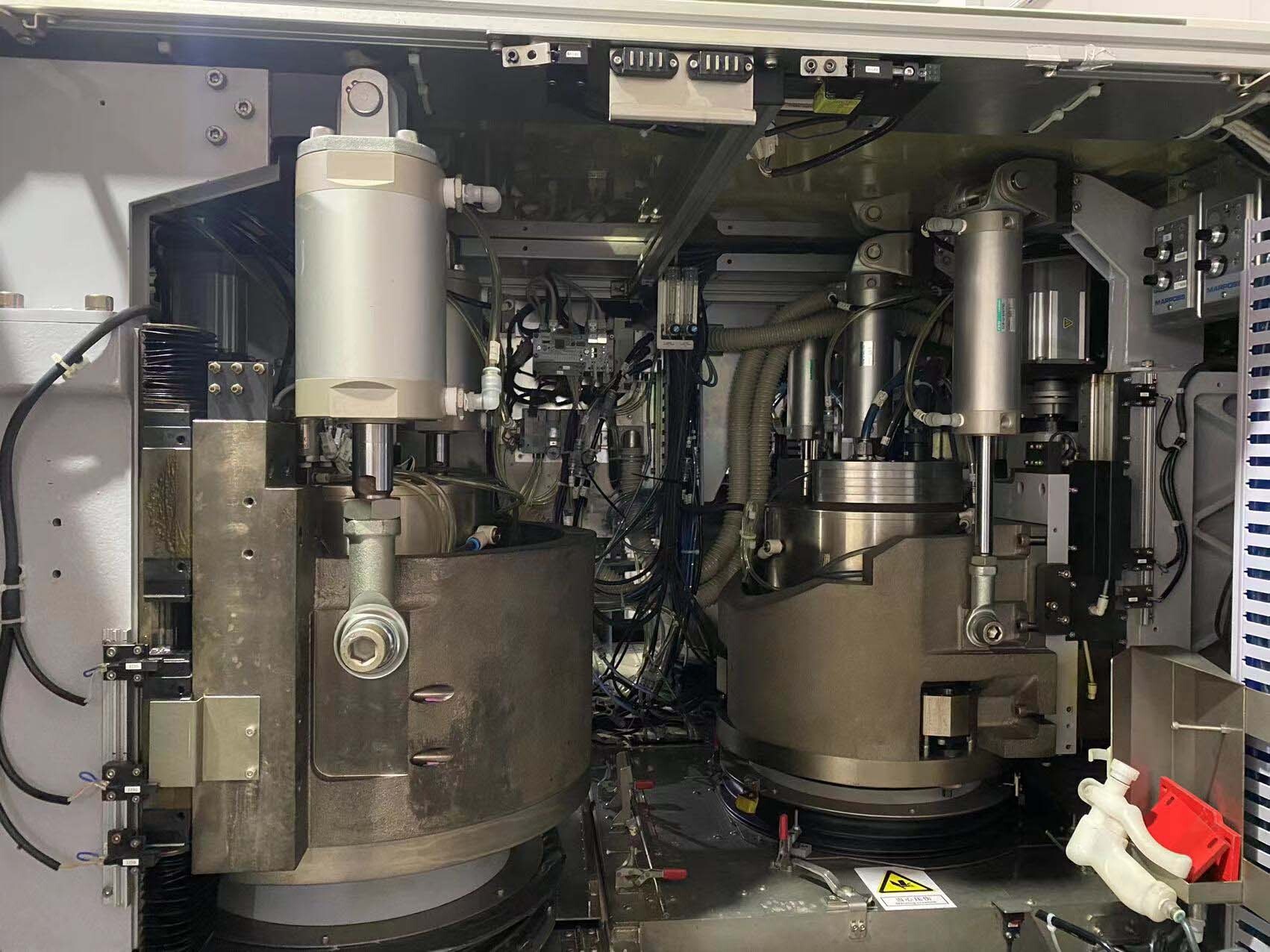

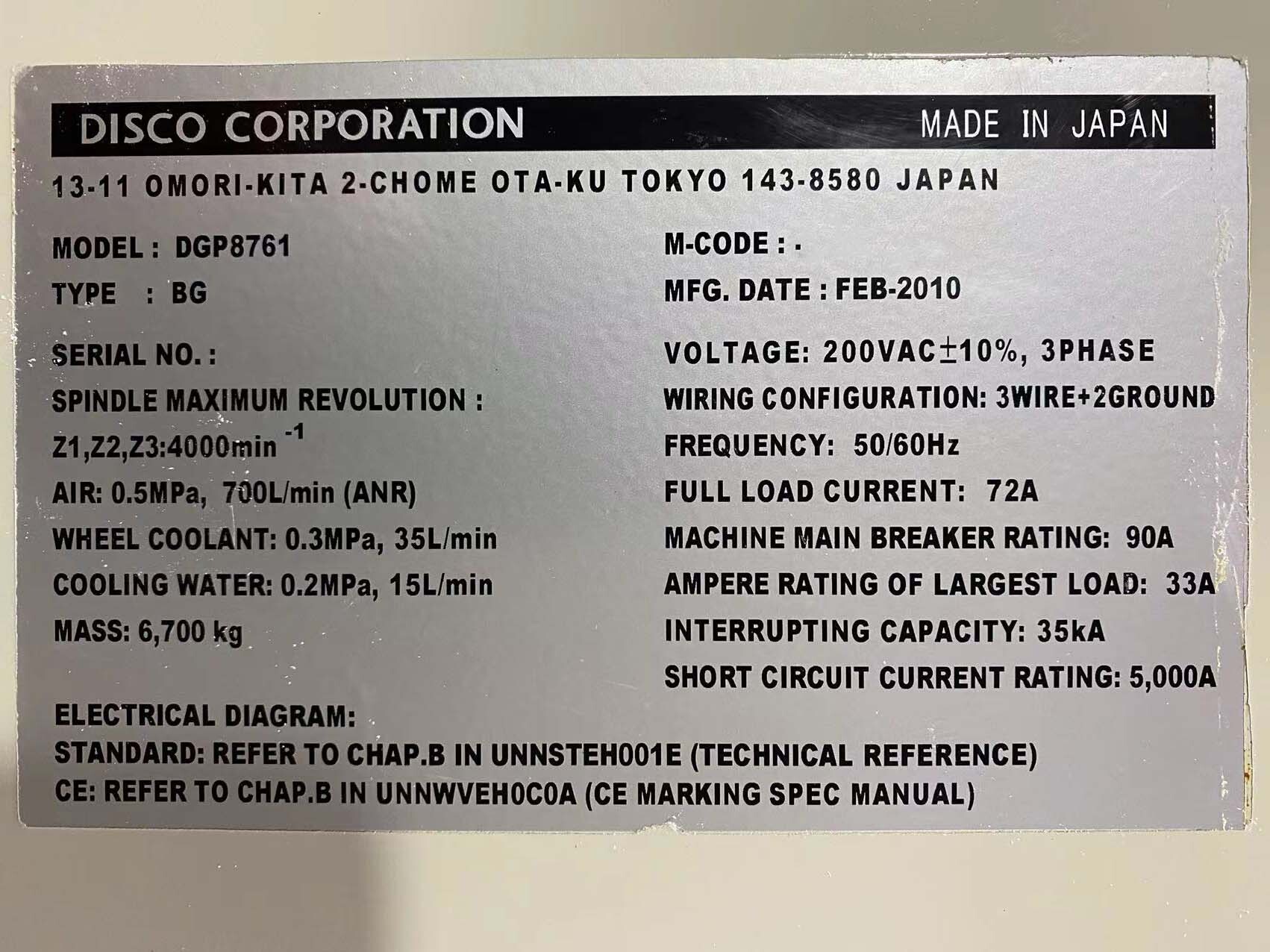

DISCO DGP 8761 wafer grinding, lapping and polishing equipment is an advanced machine designed to produce the highest quality finishes on individual wafers. The system is capable of producing finishes of a few nanometers up to a few hundred nanometers on wafers of any size up to 300 mm in diameter. It has a variety of features, including a compact, high-efficiency motor drive, a rigid body frame, massive main spindle, and a dedicated wafer holder. The main component of the unit is the grinding wheel, which is selected for the specific application and the desired surface finish. The wheel is mounted to the drive spindle by two hexagons located on either side of the wheel. The motor drive spins the wheel at speeds up to 3000 rpm and can also be electronically slowed down for finer polishing. Specialized grinding wheels are mounted to the spindle for grinding, lapping or polishing various materials, including silicon, quartz, ferrite, and even soft materials like plastics and foam. The machine also includes a vacuum Chucking unit for holding the wafer during grinding. This unit is attached to the main spindle and works in conjunction with the vacuum tool to ensure that the wafers remain securely in place even at high speeds. The chuck also has adjustable end stops for making sure the entire wafer is polished evenly, no matter the size. Another feature of DISCO DGP8761 is the ability to go from one step of the process to the next quickly and efficiently, making it ideal for finishing multiple wafers in a timely manner. The asset also includes automatic flush nozzles that help to keep the wheel and work surface clean, even at high speeds. The automatic flush nozzles are essential for preventing work surface contamination and providing a final finish with a uniform appearance. The model has a number of features that minimize operator fatigue and ensure safety for the user. It features an emergency stop button, an automatic spindle load monitor, and a vibration isolation base that ensures the equipment is noise free. In addition, the grinding wheel can be easily replaced without having to remove the wafer, saving time and increasing production efficiency. DGP 8761 wafer grinding, lapping, and polishing system is the ultimate tool for creating precise, mirror-like surfaces on any wafer up to 300 mm in diameter. Its robust construction and versatility make it a must-have tool for any wafer processing facility.

There are no reviews yet