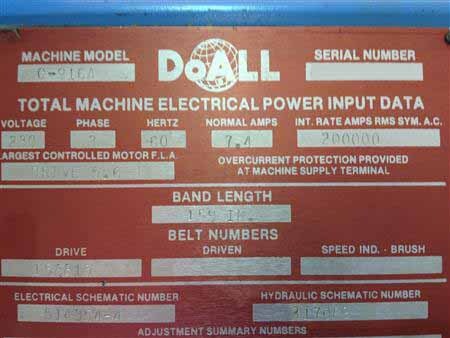

Used DOALL C-916A #9111433 for sale

URL successfully copied!

Tap to zoom

ID: 9111433

Vintage: 1995

Horizontal Saw

Capacity 9" x 16" Flats

Round Diameter 10.75"

Blade Size 159" L x 1" W

Work Height 26"

Blade Speed 105 - 275 FPM

Main Motor 2 HP

Hydraulic Clamping

Hydraulic Stock Feed Roller Table

Variable Speed Drive Adjustment by Wheel

Programmable Piece Part Counter

Coolant Selector Switch

Saw Blade Adjustment Guide

Coolant Pump

1995 vintage.

DOALL C-916A is a specialized lapping and polishing equipment ideal for working on both hard and soft materials. This system is designed to deliver a quick and cost effective method of resurfacing wafers to very tight tolerances with high surface finish quality and precision. C-916A consists of four components that are all mounted on a single mobile stand; a full diametral grinding wheel, a polishing wheel, a coarse honing wheel, and a fine honing wheel. The diameter of the polishing wheel is adjustable to accommodate wafers of varying sizes, and a wide range of abrasives can be used to meet the users' exact needs. The unit also includes two water reservoirs that act as a coolant to keep the temperature of the wafer during the grinding and polishing process. The grinder is driven by a powerful 1.5 kW motor with oscillating capability, enabling it to move across the entire surface on a reciprocating movement. This provides an even finish for all surfaces when grinding runs at higher than average speeds. At the end of each cycle, both the diameter of the grinding wheel and the abrasive used to achieve the finish of the wafer can be manually selected for specific applications. The polishing wheel is also adjustable in size and type of abrasive material, depending on the user's specifications. This wheel has a rotating movement that minimizes any potential swirl marks on the wafer. The coarse honing wheel uses 120-grit and higher abrasive materials to rapidly remove large amounts of stock, while the fine honing wheel includes a diamond abrasive suitable for fine polishing. All of the components of DOALL C-916A, with the exception of the motor, are made from stainless steel. This ensures less corrosion over time and will maintain its quality even with daily use. The machine also requires only minimal maintenance, providing a reliable and cost-efficient solution for regrinding wafers.

There are no reviews yet