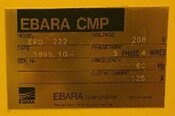

Used EBARA EPO-222 #9203985 for sale

URL successfully copied!

Tap to zoom

EBARA EPO-222 is a dual-space wafer grinding, lapping and polishing equipment designed and manufactured by EBARA Corporation for precision polishing of wafers used in the semiconductor industry. The machine utilizes a variety of grinding, lapping and polishing operations in order to produce a superior finish on both sides of the wafer, making it suitable for use in a wide range of processes, including the fabrication of advanced components such as LEDs, lasers, and MEMs. EBARA EPO222 system consists of a dual work chamber, enabling the operator to run two different and concurrent processes within the same unit. The machine comes equipped with a high-performance spindle, grinding disks, and lap plates to ensure maximum accuracy in the production of flat and round parts. The grinding and polishing process utilizes advanced technology, including accurate pressure control, to ensure a high degree of uniformity and repeatability, enabling the operator to produce parts with precise surface finish and repeatability. EPO 222 machine also comes with an automated vision tool, capable of measuring the parts with a precision of 0.001 mm. This enables the asset to accurately detect and correct shift, roundness, and radius errors, allowing for faster production of high-quality parts. Additionally, the machine comes with a safety monitoring model, enabling the operator to monitor the status of the process and to ensure the safety of the process environment. The equipment offers adjustable speeds from 0 to 999 RPM, and adjustable grinding wheel pressures between 0 and 25 kgs, enabling the operator to accurately accomodate the conditions necessary for each process. Also, the machine has a built-in self-checking system, which ensures a safe and reliable operation, and its auto-program function allows the operator to program the production process easily. All in all, EPO222 offers the operator precision, accuracy, and flexibility in the production of high-quality wafers.

There are no reviews yet