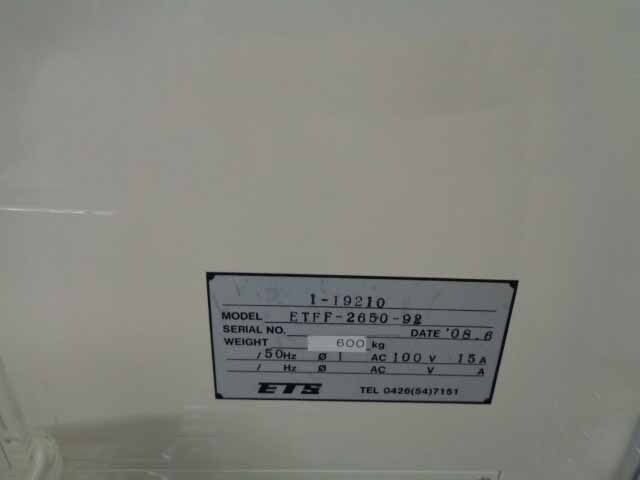

Used EBARA Frex 150 #293660146 for sale

URL successfully copied!

Tap to zoom

EBARA Frex 150 wafer grinding, lapping & polishing equipment is a high performance, multi-functional solution for meeting the most demanding requirements of semiconductor and MEMS device technology. Specifically designed for grinding, lapping and polishing the hardest kind of silicon wafers, Frex 150 provides a superior quality finish with a wide range of settings from 400-2,000 RPM and a maximum grinding pressure of 2.2x106 N/m2. EBARA Frex 150 is equipped with a built-in hydraulically powered grinding head, a 150 mm diameter Schottky wafer chuck, and a large vacuum chuck. The system is built with an upper side grinding, lapping and polishing plate as well as a lower base plate for distributing grinding pressure and support. A special Sensor Gauge Control allows for preset parameters to be used when placing the wafer onto the lapping plate for precise and detailed grinding, lapping and polishing. The unit is also outfitted with large air purge machine that can be used to remove airborne material from the grinding and polishing areas to reduce contamination and optimize grinding/polishing performance. In addition, an automated recirculation tool and triple filtration asset allow for easy and clean filtering of the liquids used for grinding and polishing. Frex 150 comes with a temperature control panel for controlling and monitoring the temperature of the materials used in the grinding and polishing process. Also included in EBARA Frex 150 is a special "profile tracking" software which allows users to preset and save their grinding and polishing parameters. This feature enables them to achieve a repeatable surface-finish profiles and a consistent material removal rate. The software also allows for a wide range of surface roughness detection and allows users to see what changes need to be made during the grinding and polishing process. Finally, Frex 150 is excellent for high-productivity applications thanks to its robust structural design and carefully designed components that ensure low noise levels, low particle emissions and excellent finish yields.

There are no reviews yet