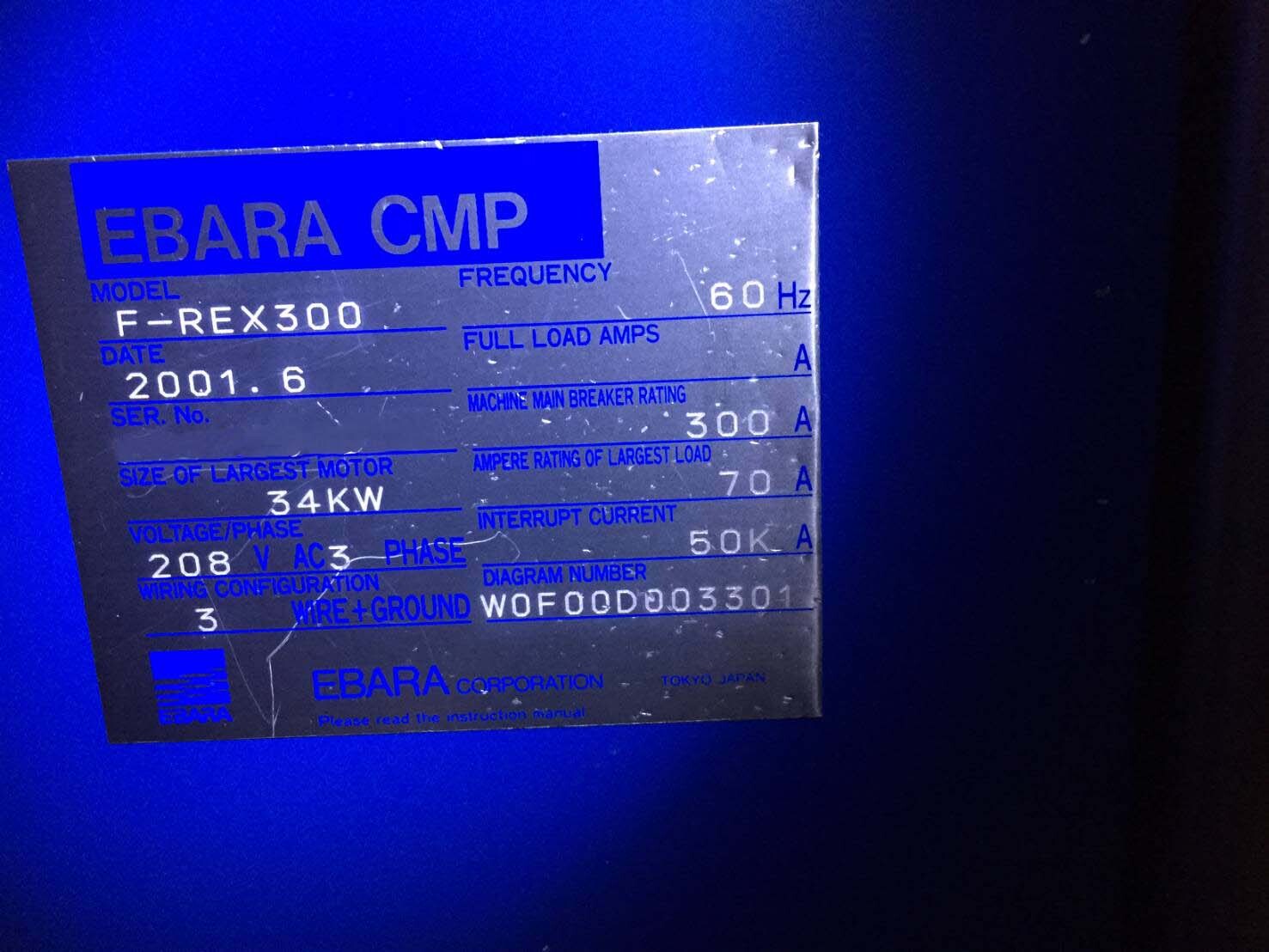

Used EBARA Frex 300 #293652216 for sale

URL successfully copied!

Tap to zoom

ID: 293652216

Wafer Size: 12"

Vintage: 2001

W-CMP System, 12"

(4) ASYST S2 load ports

Chemical connections (Bottom)

Exhaust connections (Top)

Gas connections (Bottom)

Drain connections (Bottom)

Polisher (L/R):

AL Polishing head, 12"

Endpoint: TCM and friction

Platen type: Ceramic (SIC), 10-150 RPM

Platen pad conditioner: Sweep driven, Scan dresser disc, 4”

CLC Slurry delivery

Slurry line1: ASAHI 25-250ml / min

TOKYO KEISO Platen cooling flow monitor

Platen cooling temperature monitor

Dresser DIW Flow meter: Flow range 1.0-1.5 L/min

Atomizer

Cleaner:

Type 1: Roller brush

Chemical delivery type: (1) Chem CLC 0.0-1.0 L/min

Upper flow meter: 0.0-1.0 L/min

Pencil brush spin rinse dryer

Options:

Robot D / R / L: YASKAWA

Status lamp (RYGB, Front / Rear)

Monitor 1: Front

Monitor 2: L-Side

Monitor 3: R-Side

EPD monitor: R-Side

(2) CPU:

Touch panel drawing and control version: 7.5.00

ME10 / ME20

Communication:

Controller (Logic): VME

Controller (process database): Touch panel

2001 vintage.

EBARA Frex 300 is an automated wafer grinding, lapping, and polishing equipment designed for use in the semiconductor industry. It offers extreme precision, providing up to 0.5 um finish, and high-speed operation for efficient production. The system utilizes an ultra-low force polishing unit for optimal results, with a variable speed programmable turntable for processing of a wide range of types and sized materials, allowing for maximum flexibility. It is designed for operation in a cleanroom environment with stainless steel, corrosion-resistant cages, and laminar air flow hoods. The machine consists of a 6-axis robot, an Advanced CNC grinder, and a twin-disc lapping arm. The robot is capable of moving wafers, working with four wafers at a time, and is equipped with two linear axes and two rotary axes. It is integrated with the CNC grinder through a servo-motor, which provides precise control and faster processing speed. The CNC grinder includes a high-precision table, ideal for wafer grinding, lapping and polishing. The twin-disc lapping arm uses a flat and a contoured faceplate, to precisely polish both flat and curved surfaces, enabling precision control and minimizing cycle times. The tool also offers a range of customizable options for a variety of applications. It can be configured to accommodate different sizes of wafer platforms, and is equipped with a wafer cleaning station, pressure control valves, and air knives for efficient transfer of wafers. Additionally, the asset can be extended with additional features, such as different lapping disks, Chuck jaws, and other accessories. EBARA FREX-300 has been designed to facilitate a straightforward and easy operation. It offers a range of safety features for operator safety and protection, and is capable of providing exceptional fabrication results with high accuracy, reliability, and efficiency.

There are no reviews yet