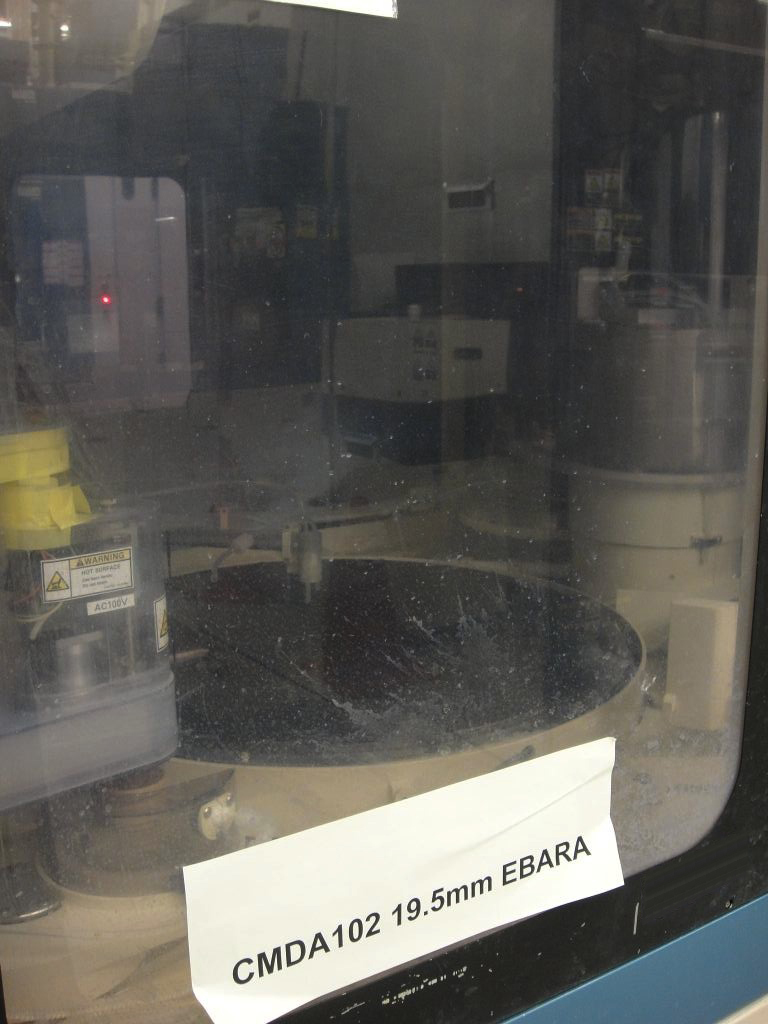

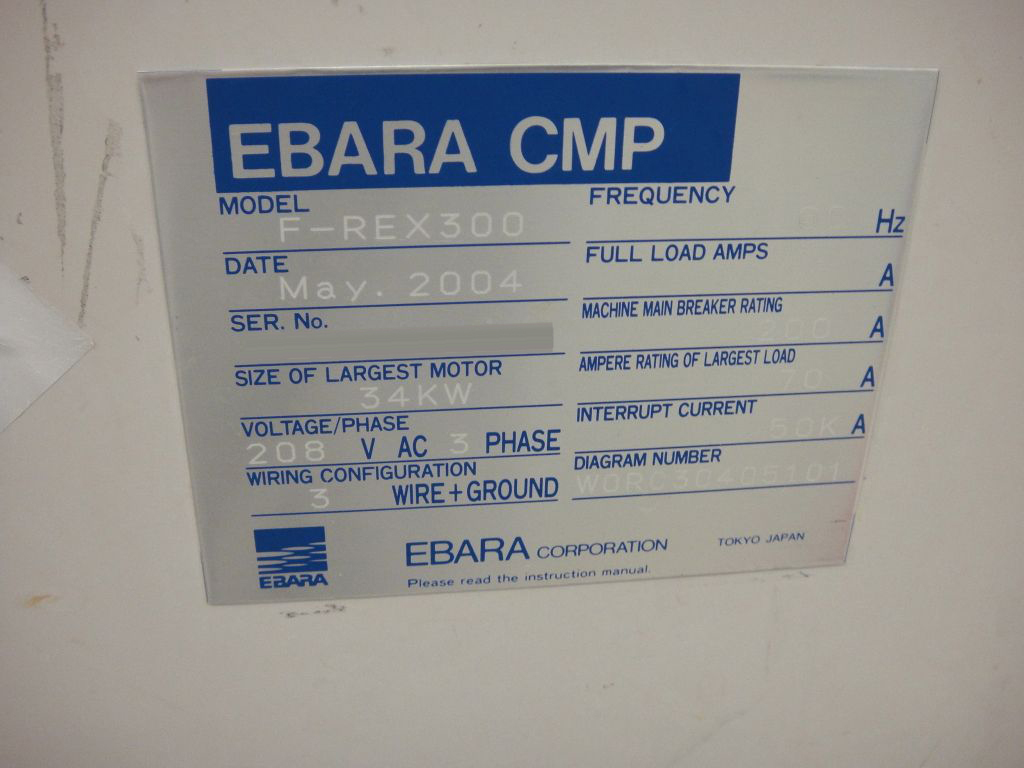

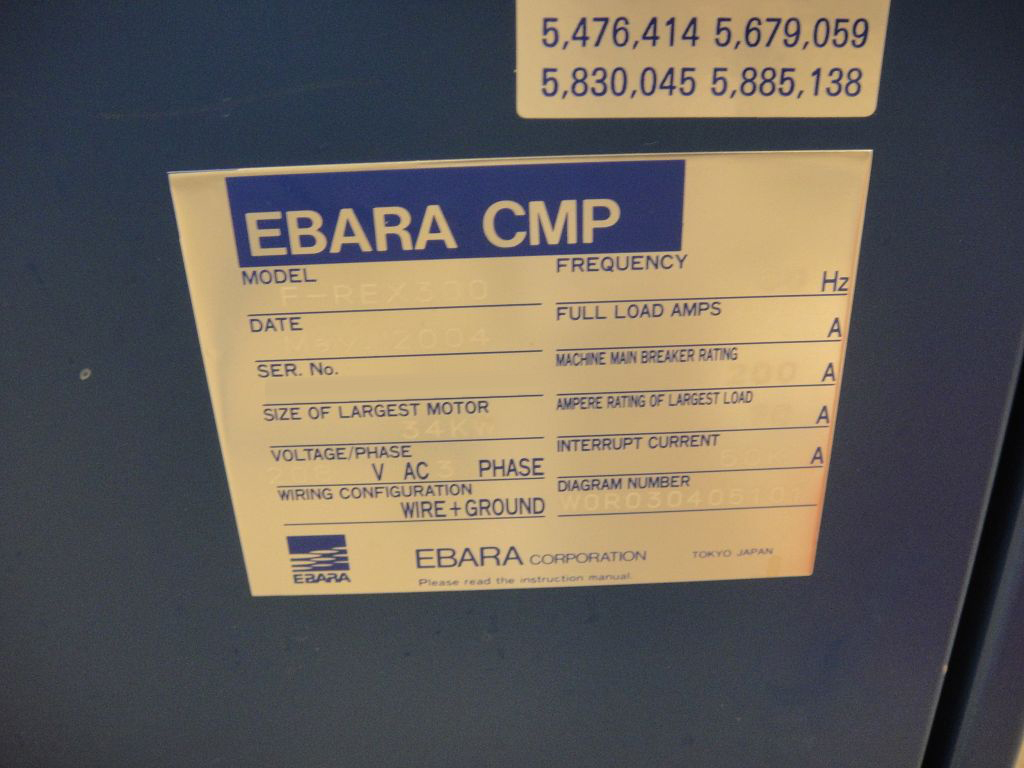

Used EBARA Frex 300 #9017351 for sale

URL successfully copied!

Tap to zoom

ID: 9017351

Wafer Size: 12"

Vintage: 2004

Poly / STI CMP system, 12"

Factory Interface (FI):

Frame config: metro ready

Load-port type: (4) Asyst ISO

Pre-aligner

Wafer handling robot: track type with dual end effecter

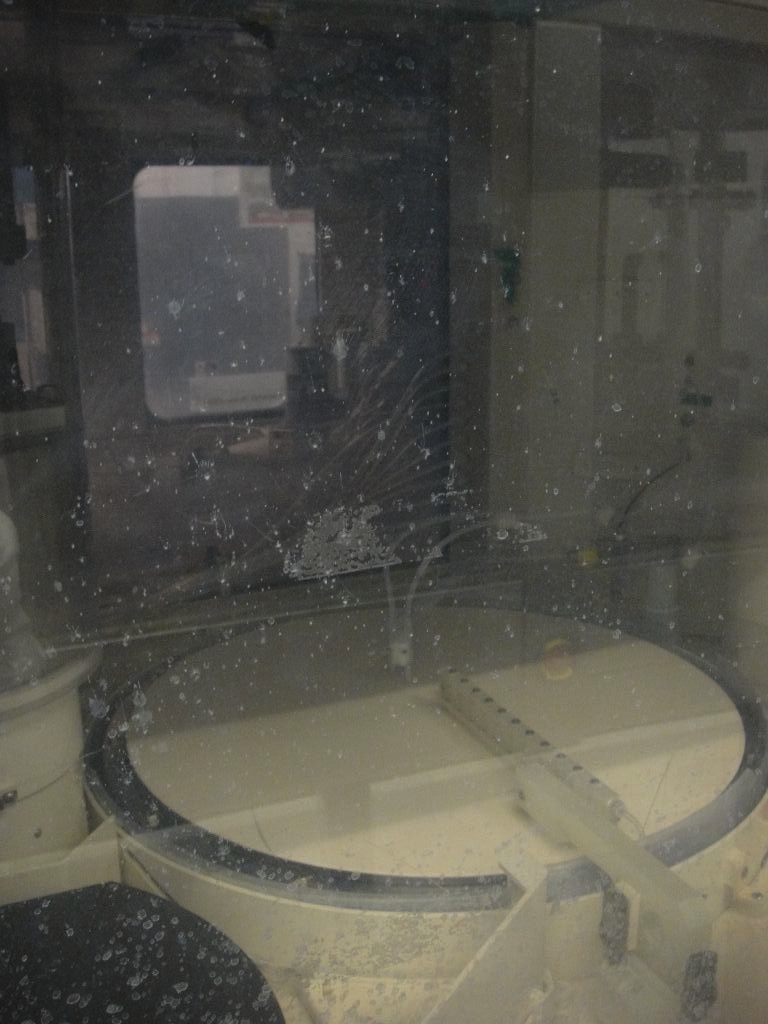

Polisher (L/R):

Process (L/R): STI

Polishing heads: 300 mm AL head, gen. II

Endpoint: TCM and friction

Platen type (speed): ceramic (SIC), 10-150 rpm

Pad type: IC1000

Platen pad conditioner: scan dresser 4” disc (3M 5122-AB), sweep driven

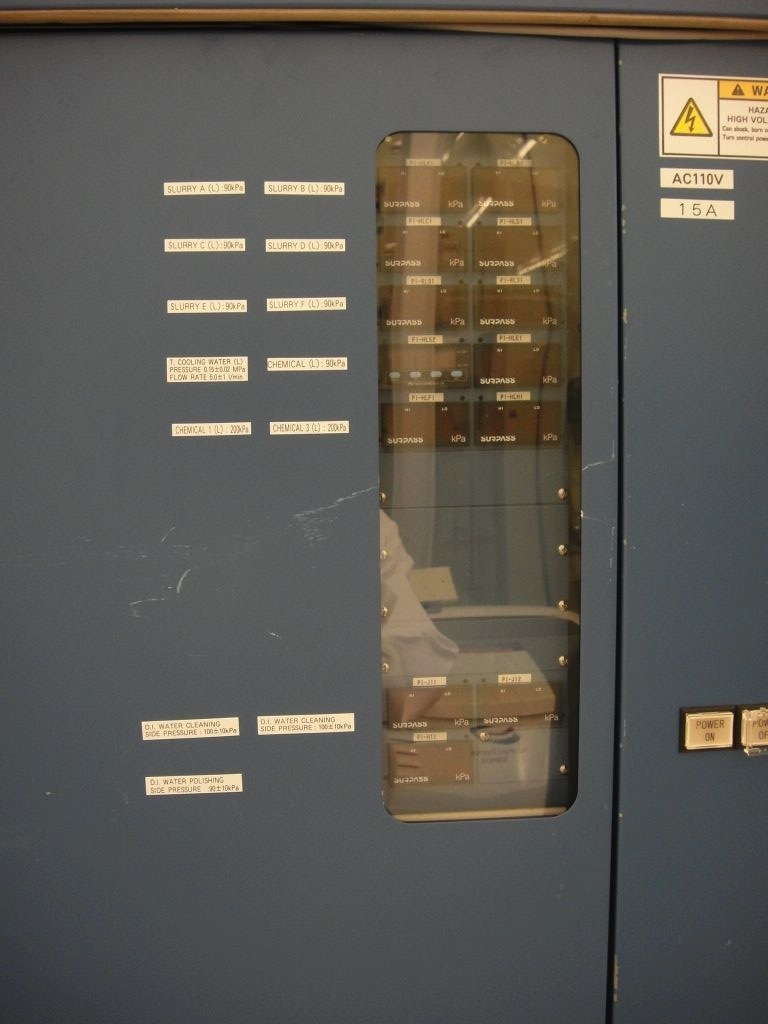

Slurry delivery: closed loop (CLC) delivery

Slurry flow range: 25-250 mL/min (low flow rate)

Slurry line 1: HS-8800

Slurry line 2: none

Slurry line 3: none

Wafer slip-out sensor: yes

Wafer loss camera: no

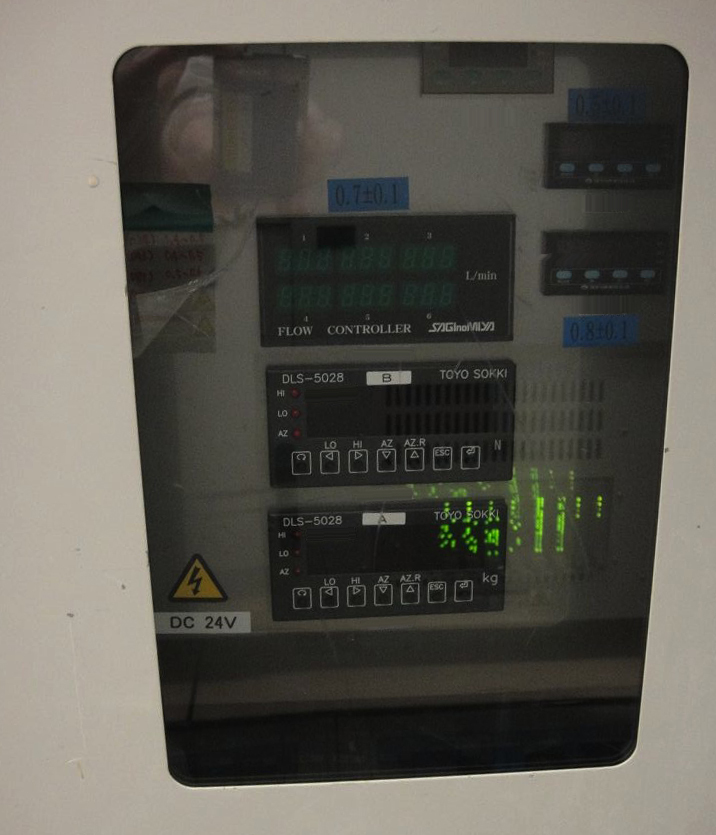

Platen cooling flow monitor: Tokyo KEISO

Platen cooling temp monitor: user configurable alarm settings

Dresser DIW flow meter: flow range 1.0-1.5 L/min

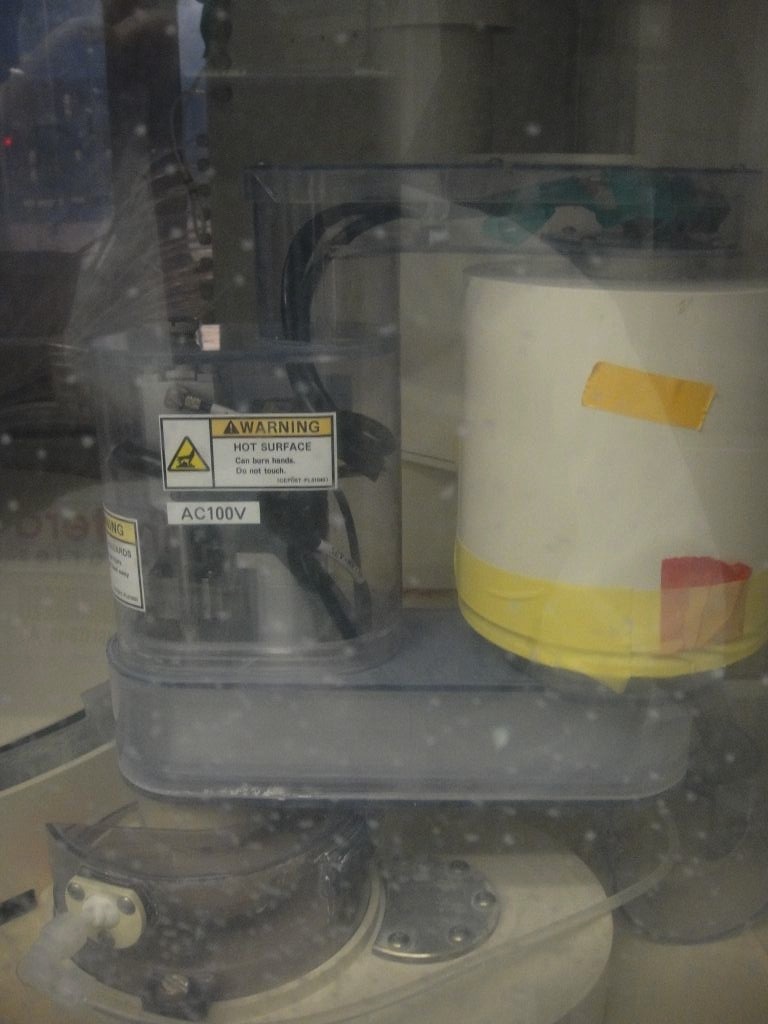

Atomizer: yes

Endpoint (L/R):

Table current monitor (TCM): yes

Multi-process monitor ME20 for EPD: yes

Metrology option: none

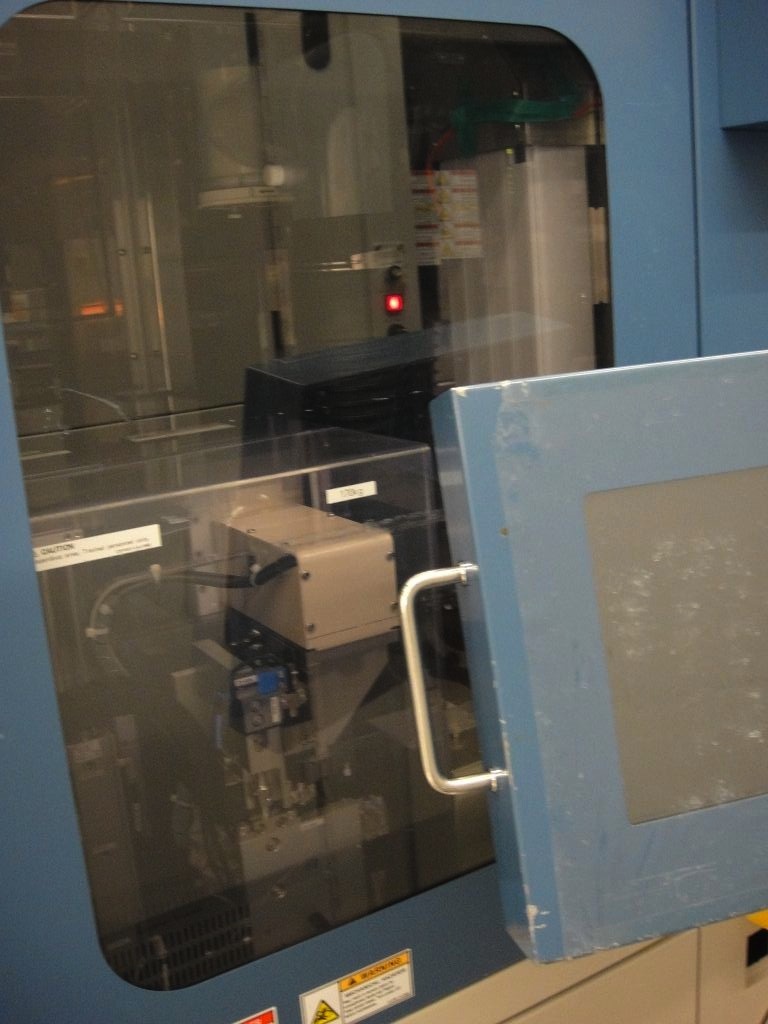

Cleaner (L/R):

Cleaner 1 type: roller brush

¬ Note: no megasonic

¬ Chem. delivery type: (1) chem CLC 0.0-1.0 L/min (alarm capability)

¬ Chemical 1 upper flow meter: 0.0-1.0 L/min

¬ Chemical 1 lower flow meter: 0.0-1.0 L/min

¬ Chemical line 1: HF

¬ Chemical line 2: n/a

¬ Bevel edge cleaning: yes

Spin rinse dryer: pencil brush

¬ Chem delivery type: (1) chem CLC 0.0-1.0 L/min (alarm capability)

Options:

Robot D: Yaskawa

Robot R: Yaskawa

Robot L: Yaskawa

Status lamp (RYGB, front/rear)

Monitor 1: front

Monitor 2: L-side

Monitor 3: R-side

EPD monitor: R-side

Software:

Main SW ver: 7.5.02

CPU-1 (OS/9) ver: 7.5.02

CPU-2 (OS/9) ver: 7.5.00

Touch panel control ver: 7.5.00

Touch panel drawing ver: 7.5.00

Online ver: 7.5.00

ME10/ME20 ver: 2.4.30.0

Communication:

Controller (logic): VME

Controller (process database): touch panel

Heat exchanger / chiller:

(1) Advanced Thermal Sciences SX-21

Facility:

Seismic support: bracket locations to be provided

Chemical connections: bottom

Exhaust connections: top

Gas connections: bottom

Drain connections: bottom

Power requirements: 208 VAC (3.4 kW) , 200 A, 3 phase, 3 wire+ground, 60 Hz

2004 vintage.

EBARA Frex 300 is a wafer grinding, lapping and polishing equipment that is capable of achieving superior results at high production rates. This automated system is designed to run wafers up to 300 mm in diameter, efficiently and reliably producing superior results with an accuracy of 1 micron or less. The unit utilises material removal techniques to achieve the highest levels of surface finish. It can simultaneously process a number of substrates and has built-in process parameters for a wide variety of wafers. The machine is controlled by a Graphical User Interface (GUI) which facilitates easy operation and adjustment. When used in conjunction with ELID (electrolytic in-process dressing) grinding, EBARA FREX-300 is capable of achieving high removal rates on many types of substrate. This process utilises a stationary diamond grinding wheel to remove material and then a non-rotating abrasive pad to level and finish the workpiece. This results in an improved level of surface flatness when compared to conventional grinding methods. F-REX300 is equipped with an automated spindle changer, allowing quick transition between different wafers and different processes. This tool uses a wide range of grinding spindles and tools to meet the needs of various production requirements. The spindle changer is programmable and is able to move from one operation to the next quickly and accurately. The asset has a self-diagnostic model to check for any errors, and a visual alarm for help to quickly identify any issues. The built-in safety measures are designed to protect the equipment from damage and ensure that no damage is done to the wafers. FREX-300 is also designed to be energy-efficient and is capable of achieving significant energy savings through the use of efficient motors and advanced control systems. Overall, EBARA F-REX300 is an advanced wafer grinding, lapping and polishing system capable of producing superior results with excellent accuracy and repeatability. This unit is an ideal choice for high-volume applications and provides users with an efficient, reliable and cost-effective solution to their production needs.

There are no reviews yet