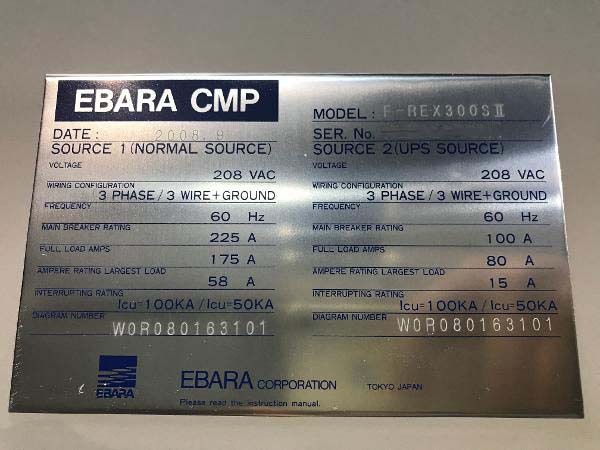

Used EBARA Frex 300S #293625791 for sale

URL successfully copied!

Tap to zoom

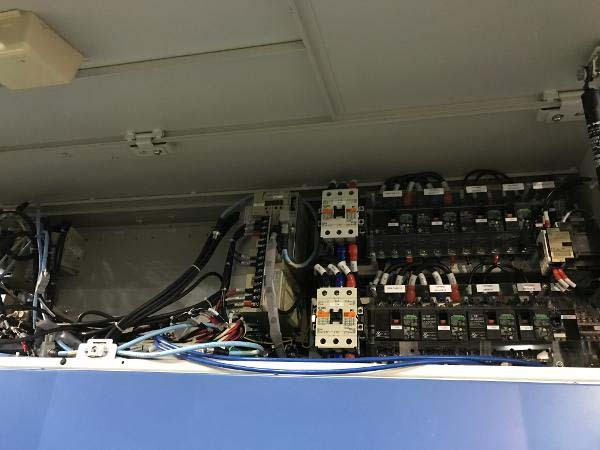

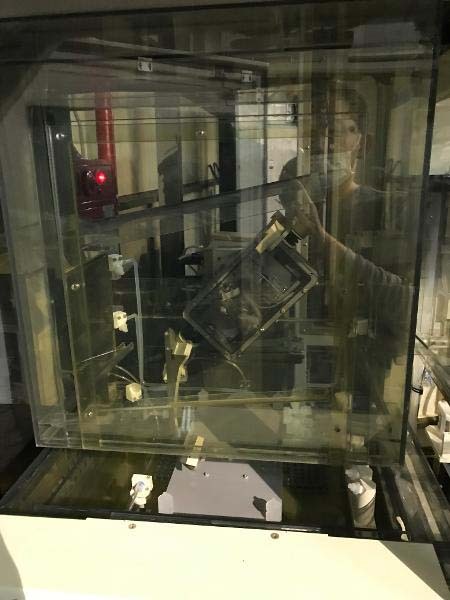

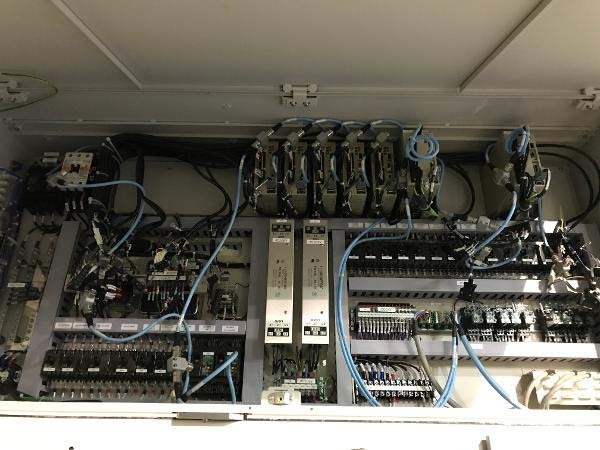

EBARA Frex 300S is a state-of-the-art wafer grinding, lapping and polishing equipment. It is a fully automated, CNC-controlled system capable of producing multi-crystal, multi-level and custom patterned semiconductor wafers. The unit is equipped with a 6-axis motion machine, digital video microscope, closed loop position and pressure servos, and a special robotic arm with a precision end-effector. EBARA FREX300S is designed to maintain a high level of roundness, surface flatness and wafer thickness accuracy. The tool features a abrasive media grinding/polishing head with an adjustable pressure and feed control, giving the operator utmost control over machining process parameters. The robotic arm allows for precise positioning and handling of wafer during the grinding process. F-REX300S also offers an advanced lapping process that ensures a high degree of polishing accuracy. This process involves sawing the wafer into an initial shape, then grinding it to finished dimensions. This stage of the process is performed by a circular movement of the grinding/polishing head while the belt grinders provide a high-precision finish. EBARA FREX-300 S achieves excellent surface finish quality and wafer uniformity. It is equipped with a digital video microscope and spectrometer to monitor surface quality, particle analysis and shape profiles. The asset is also compatible with various types of polishing compounds and diamond-grade suspension slurries. Overall, EBARA FREX 300 S offers a high level of automation, accuracy and wafer quality control that is essential in minimizing defect rates in the semiconductor fabrication process. With its combination of advanced grinding and lapping technology, F REX 300 S is a proven industry leader in the development and manufacture of high quality semiconductor wafers.

There are no reviews yet