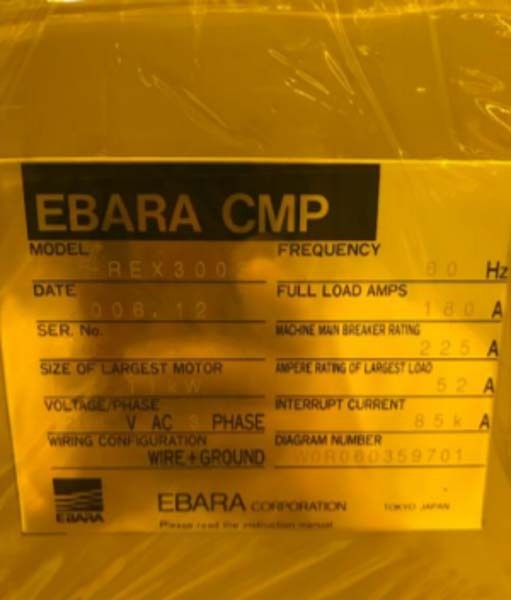

Used EBARA Frex 300S #9382430 for sale

URL successfully copied!

Tap to zoom

EBARA Frex 300S is an advanced vertical spindle, rotary table type wafer grinding, lapping and polishing equipment. This system is designed to efficiently and accurately accomplish precision surface finish, flatness and roundness on wafers of up to 300mm diameter. Designed for process development and high-volume production, the unit is equipped with two grinding/polishing automatically traversing tables, an abrasive slurry delivery machine, Ceramic bonded slurry application tool and a dye removal asset. All of these components are designed to work together to produce a high-quality and consistent finish. The systematic approach influences the overall model design. The user-friendly PLC (Programmable Logic Controller) allows for easy setup and measurements. Its ergonomic configuration includes the controlled charge of the abrasive slurry, and the quick stroke-adjustable rotation of the rotary tables. The rotary tables are driven by closed loop stepping motor for precise, repeatable process control. The design of the rotary table allows flexible fine-tuning to meet substrate shape requirements. They are also protected from disk breakage by the advanced safety functions. The abrasive slurry delivery equipment ensures even abrasive slurry delivery to each wafer. Containing two ceramic bonded slurry application systems, EBARA FREX300S allows for the precise adjustment of pressure, temperature and liquid supply to satisfy specific processing requirements. The dye removal system provides the ability to quickly change abrasives without the need to manually unclog the residue. F-REX300S is engineered to provide superior performance and accuracy on the highest volume production work. The unit is designed to reduce the chances of particle contamination and ensure a uniform surface finish. With its simple and reliable design, the machine aims to provide consistently superior wafer surface quality.

There are no reviews yet