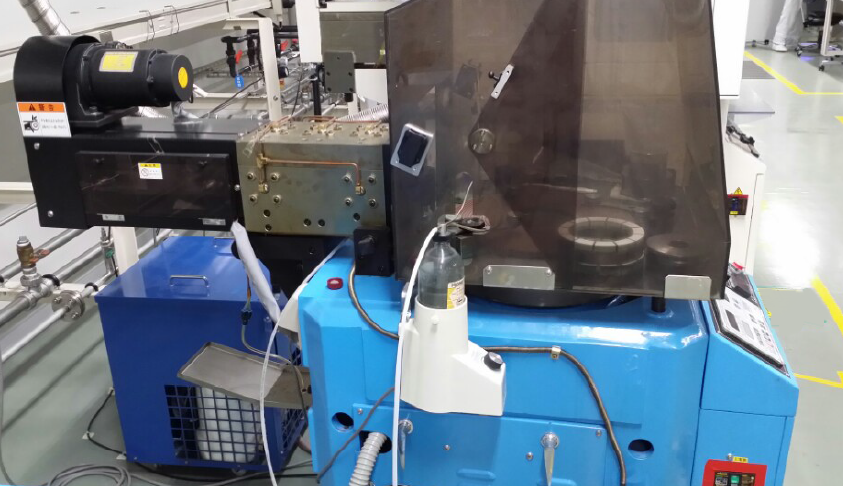

Used ENGIS EJW-400IFN #9107357 for sale

URL successfully copied!

Tap to zoom

ENGIS EJW-400IFN is a revolutionary wafer grinding, lapping and polishing equipment designed for advanced semiconductor device fabrication. This system utilizes advanced technology to process advanced semiconductor devices in a more efficient manner with higher yields and quality, ultimately resulting in decreased production costs. The unit is equipped with a high-precision, 400mm capacity grinding, lapping and polishing machine, an aspirator to filter particles, a dust collector and a measuring/ interpreting device to control the entire process. This machine requires virtually zero-maintenance and provides fully automated operation. EJW-400IFN has a load capacity of up to 400mm wafers, providing a maximum per-cycle capacity of 30-pieces of 4-inch wafers. The tool has a variable-speed motor and can process wafers from 0.12 - 1.5mm thickness. The lapping process is carried out by both fixed-abrasive and free-abrasive methods to meet different accuracy demands. The polishing process uses 1000 +/- 10 μm abrasive particles under low pressure, allowing for high precision processing. The asset offers a high level of throughput, with the ability to process up to 180 pieces of 4-inch wafers in an eight-hour shift. This efficiency is further enhanced by the combination of a static-dynamical motion mechanism and reciprocal feed motion to ensure fast chip removal. The model utilizes a step-dwell operation with a graphite adapter, yielding superior wafer quality with low particle release. For safety, the equipment is equipped with automated monitoring and a mechanical stopping function which will stop the system if the grind plate becomes excessively charged or blocked due to foreign objects. The unit is also designed for low noise emissions and protective shielding. Overall, ENGIS EJW-400IFN is a state-of-the-art and efficient wafer grinding, lapping and polishing machine specifically designed to produce high quality semiconductor devices, and is applicable for many diverse applications. The tool is ideal for those looking for a reliable, cost-effective, high-throughput solution for processing advanced semiconductor devices.

There are no reviews yet