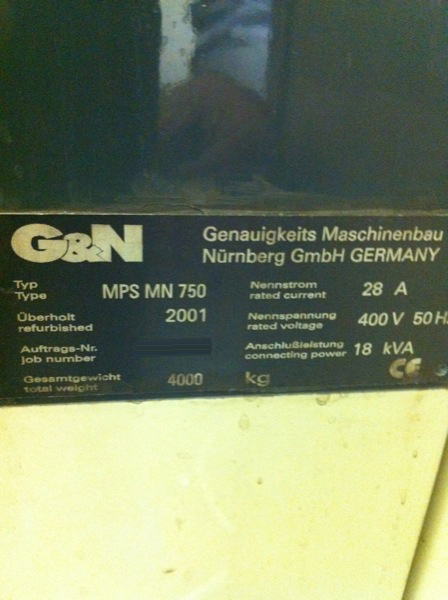

Used G&N MPS 940 #194462 for sale

URL successfully copied!

Tap to zoom

G&N MPS 940 is a comprehensive wafer grinding, lapping and polishing equipment. It integrates utilities and accessories for the production of high-quality, ultra-flat, repeatable wafer surfaces. This system has a multiple control unit to allow simple setup and operation. It features an adjustable tilt mechanism, which ensures uniform grinding rate and surface finish across the full surface of the wafer. MPS 940's tilt range of 2 to 26 degrees helps achieve uniformity in spite of varying hold times, down-force, and grinding pressure. The machine also features lubrication and cooling systems, featuring a stainless steel feed-through machine and advanced cooling mechanisms, which help reduce the temperature of the grinding media. This helps protect the delicate micro-structure of the wafer throughout the grinding process. The grinding media can be manufactured using either ceramic or diamond materials, making G&N MPS 940 suitable for processing a broad range of materials. The grinding media is fed to the work deck by means of a programmable hopper tool, with a maximum media size of 200 microns. This ensures that the feed rate and size of the grinding media are always consistent. The lapping and polishing process is performed in the same asset, which eliminates the need for two separate machines. The precision belt polisher can polish the wafers to 10 nanometer surface finish. The polisher has a built-in computer control model that allows the operator to adjust the speed and pressure of the polishing surface, and the tilt and position of the wafer. Overall, MPS 940 is an advanced wafer grinding, lapping and polishing equipment, offering accuracy and efficiency. The system ensures optimal surface finish for subsequent wafer testing and production stages.

There are no reviews yet