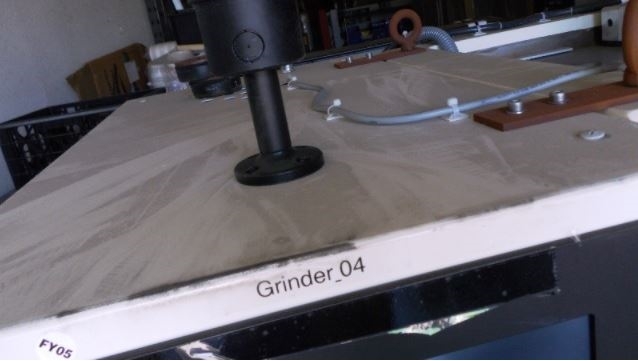

Used G&N V400 #9208430 for sale

URL successfully copied!

Tap to zoom

ID: 9208430

Ceramic wafer grinding machine

With its polymer concrete casting for better vibration absorption

Improve structural integrity

Rigidity & stiffness to grind advanced materials

Technical data:

Motor: 4 kW

Spindle speed: 1450 RPM

Total connected load: 8 kW

Chucks: 28x2” 16x3” 12x4” - 9x5” 6x6” 3x8” 1x12”

Rotary tabl: 520 mm

Rotary table speed: 1 - 30 rpm

Cup grinding wheel:

Vitrified: 250 x 40 x 76

Diamond / CBN: 250 x 40 x 76

Z-Axis & rotary table motion: PMAC-Lite (4 Axes) Control

Compressed air: 60 - 90 PSI

Fine down feed:

Range: 200 mm

Step: 1 µm

Machine control:

Retrieve data and communicate directly with program 15" TFT touch screen & industrial computer support

Dual spindle machine for fast stock removal & ultra-fine surface finish

Coolant treatment:

Closed-loop chiller controls grinding coolant temperature & coolant

Integrated filter system separates Ga As & other material particles for disposal & reclaiming

Power supply: 220/380/440 V, 60 Hz.

G&N V400 Wafer Grinding, Lapping and Polishing Equipment is a powerful and highly efficient machine designed for wet- and dry-grinding, lapping and polishing of silicon wafers up to 8" diameter. The system is composed of an enclosed stainless steel grinding tank, with integrated circulation and filtration systems, a vertical motor-driven base plate, and an upper polishing platen, all connected to the computer-controlled main controller. The unit operates using a unique 3-axis motion machine, consisting of a vertically orientated motor-driven base plate, for rotation and tilt adjustment, and an upper polishing platen, providing a precise lateral and radial movement. The motion tool provides a highly accurate and precise grinding and polishing result. The polishing platen is equipped with a precision air bearing for vertical rotation of the wafer. The wafer grinding process is controlled via a dedicated control unit which allows the user to adjust the parameters such as grinding speed, pressure, time and shape of grinding stone or pad. The asset is also equipped with a high-precision touch probe to ensure accurate surface roughness measurements can be taken during the grinding process. The model can be further equipped with a range of accessories designed to improve productivity. A rotating turret-style lifting equipment is available, which provides quick and easy loading and unloading of the wafer into the grinding tank. A vacuum fixture system is also available for perfect alignment of the wafer. V400 Wafer Grinding, Lapping and Polishing Unit is a highly efficient and precise production machine suitable for a range of thin-film and wafer applications. The fine control and easy loading and unloading capabilities make the tool ideal for batch processing, providing excellent quality and productivity.

There are no reviews yet