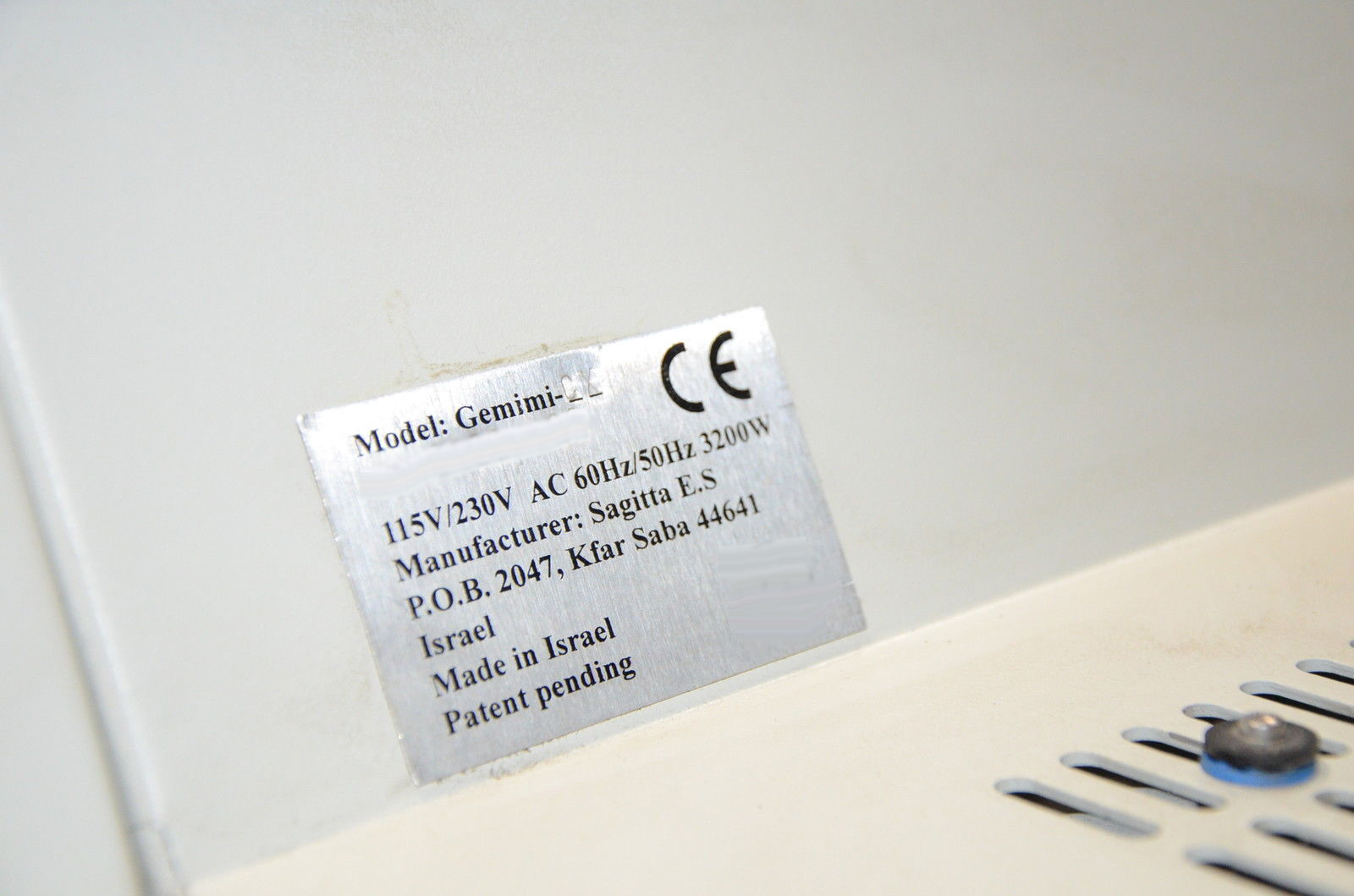

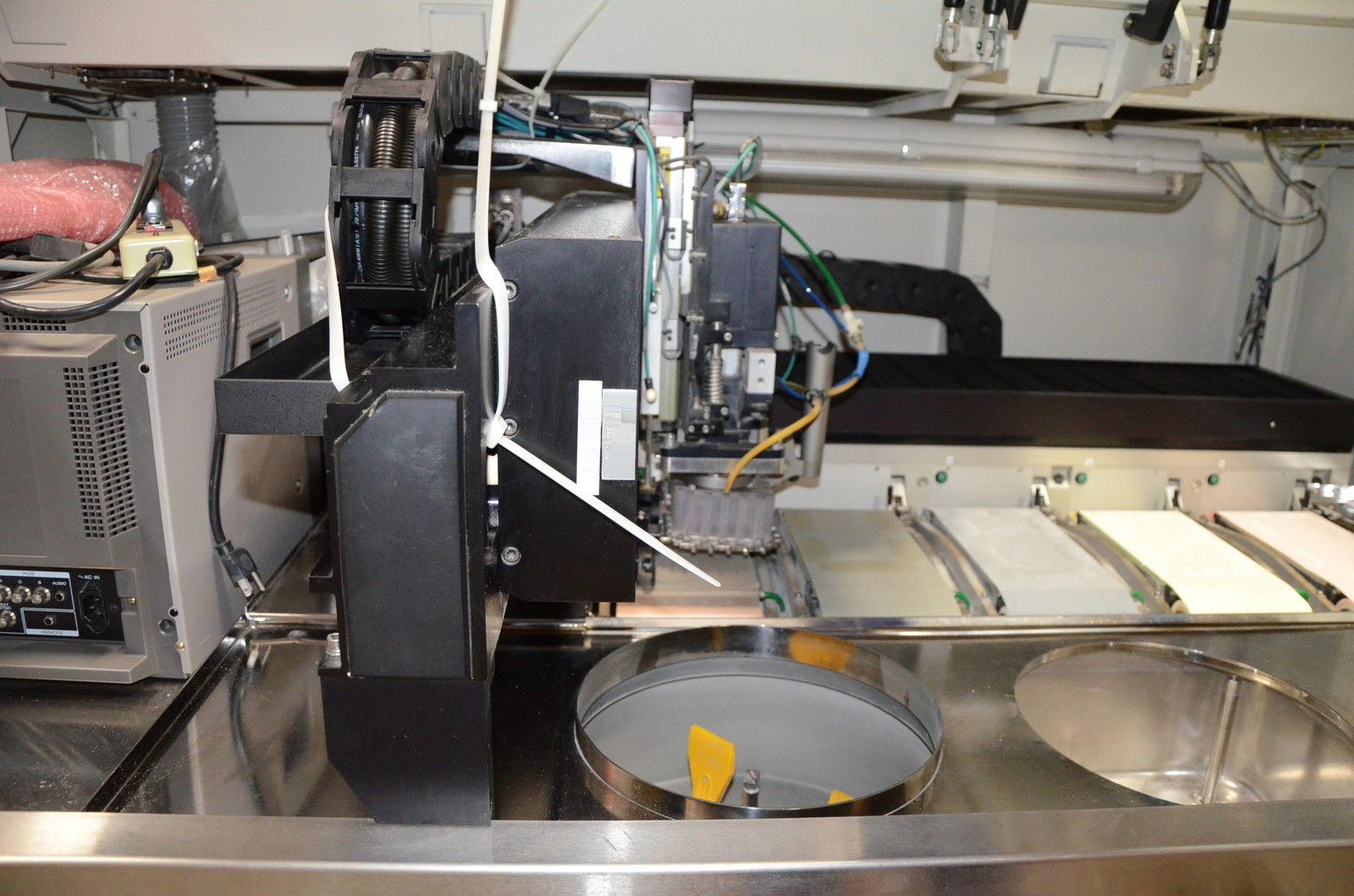

Used GATAN / SAGITTA Gemini CX #9131544 for sale

URL successfully copied!

Tap to zoom

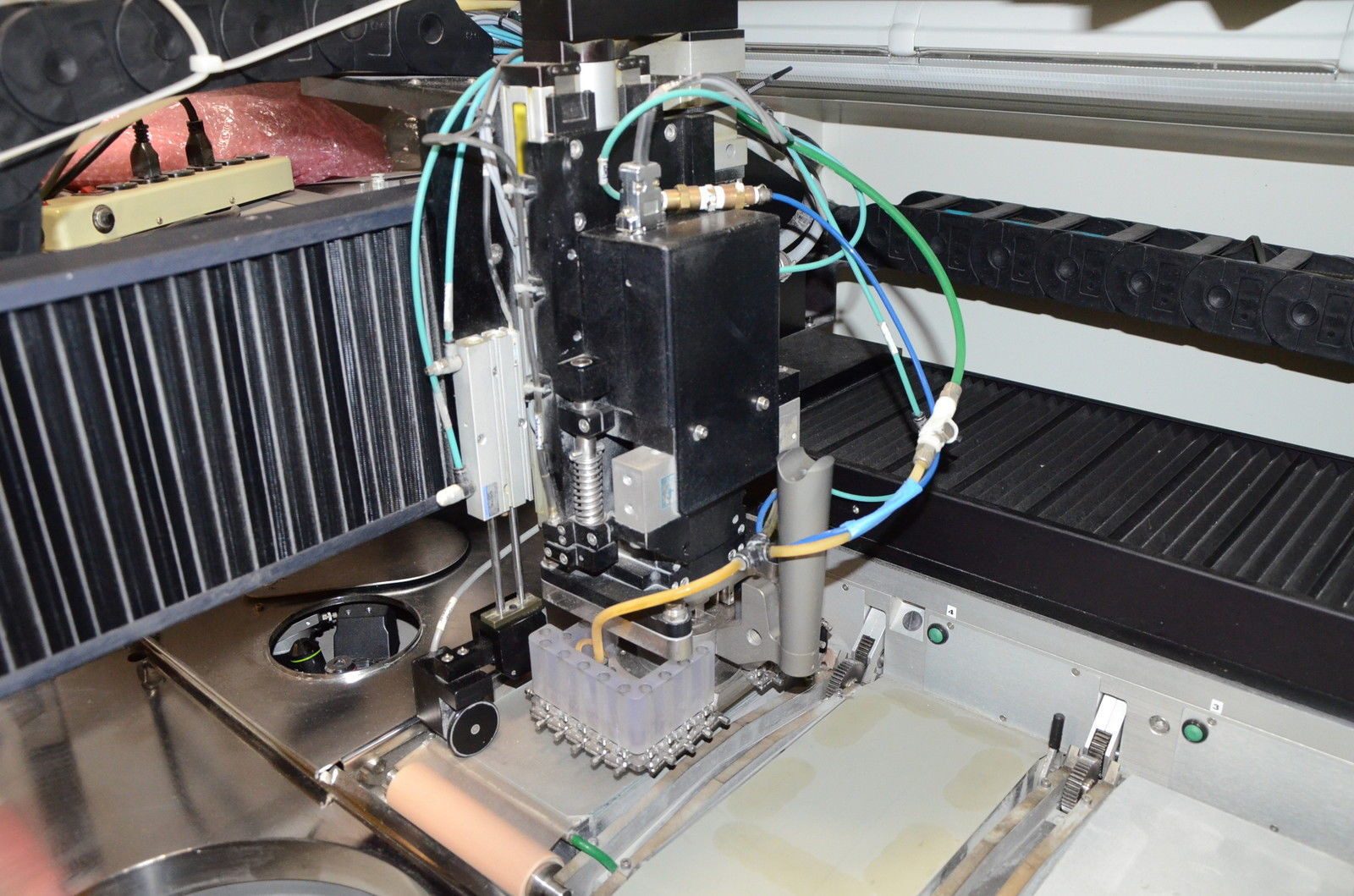

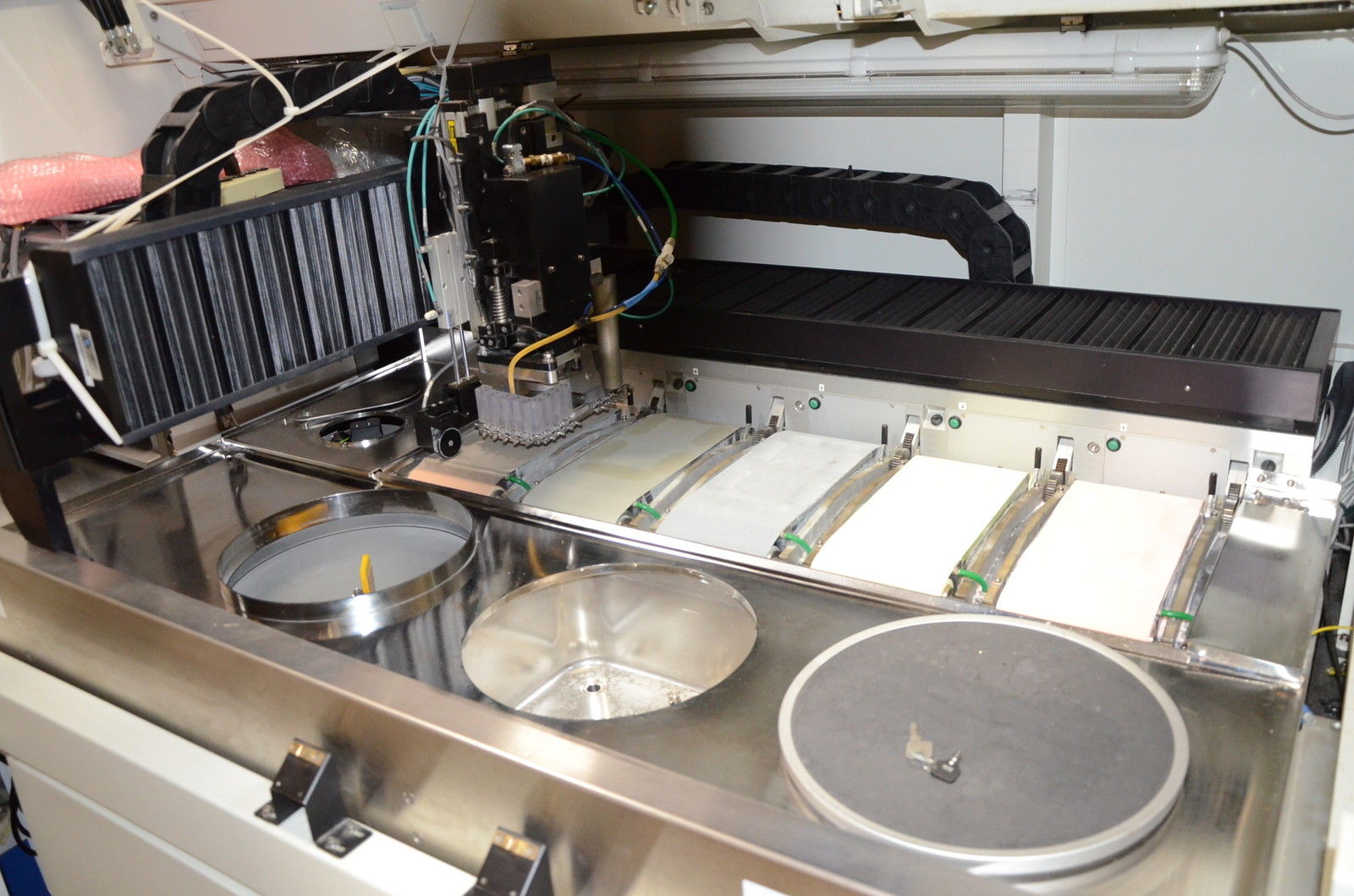

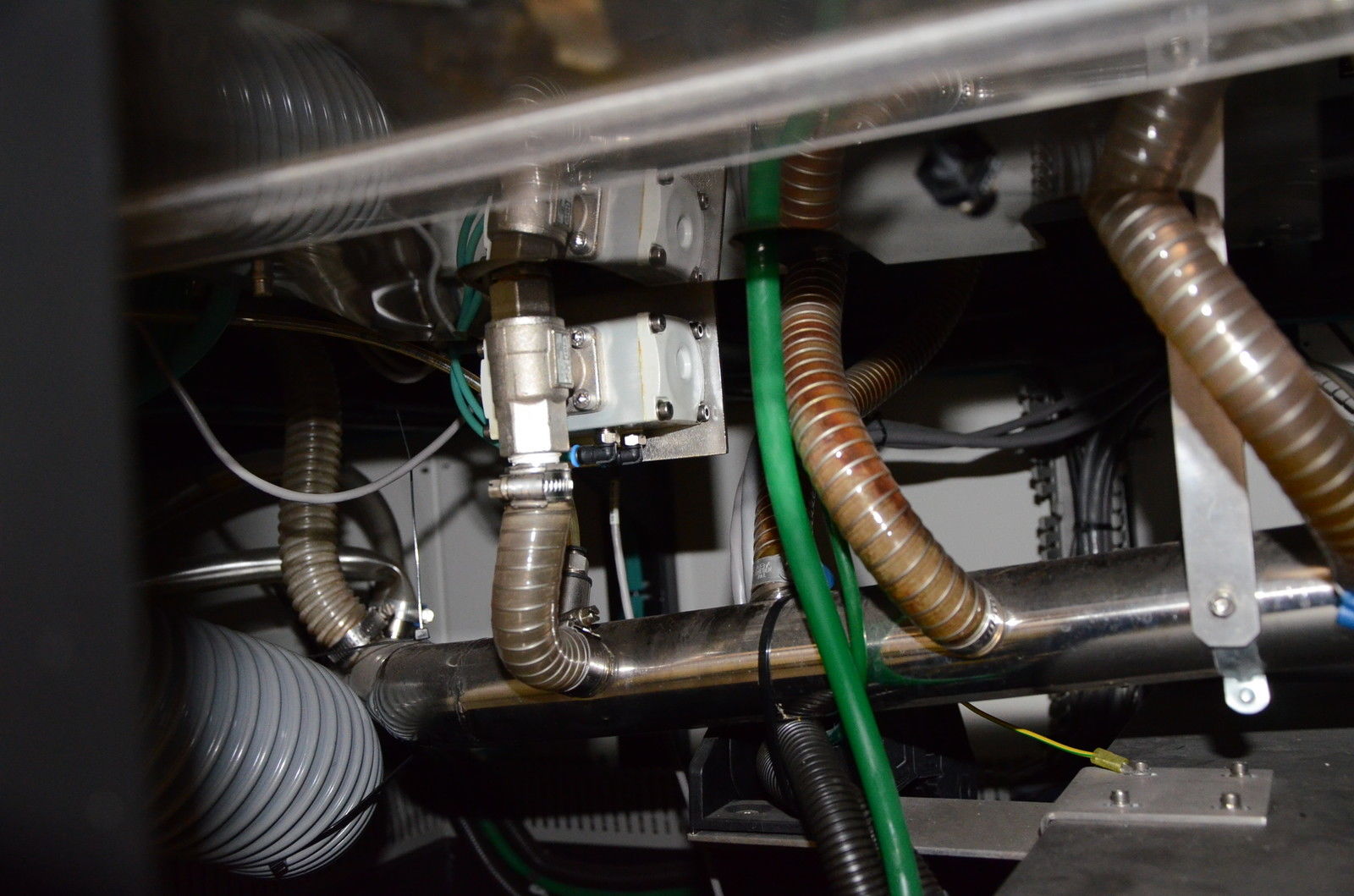

GATAN / SAGITTA Gemini CX is a combination of a wafer grinding, lapping and polishing equipment. It is specifically designed for a single wafer process. This system is multi-step and requires five separate parts to complete the process. The first step is wafer grinding with diamond grinding media. This uses a grinding action to reduce grain size and ensure a uniform surface finish. The second step is lapping with a low-pressure application of diamond lapping media which polishes and smooths the surface without altering the flatness or shape. The third step is polishing. This uses an abrasive slurry to reduce the surface roughness and create a planarized surface. The fourth step is lapping with a higher-pressure application of diamond lapping media which refine the surface uniformity. The fifth and final step is chemical-mechanical polishing, which use an active chemical solution. This step cleans the surface, reduces polishing time, and creates dielectric layers that makes the wafer suitable for semiconductor devices. The main components of GATAN Gemini CX unit are the grinding/polishing unit, the electromechanical motion and semi-automated controls. The grinding/polishing unit can hold and process one wafer at a time. It is equipped with a wafer chuck, pad holder, and diamond abrasive media. The electromechanical motion is provided by stepping motors, and the machine is controlled by a microprocessor. This allows precise movement and alignment of the wafer, along with accurate control of the spinning speed and pressure. The controls provide feedback on the process and provide user-input options to control variables and parameters. This tool can also run automated processes, using preset parameters to automatically grind and polish a wafer. SAGITTA Gemini CX asset is a cost-effective wafer grinding, lapping and polishing model that is capable of producing superior results. It is designed for use in a single-wafer operation, and is highly automated. It is built with heavy-duty construction and has a variety of features designed to ensure accuracy and consistent results. Its automated processes are easy to use, and it can be used to achieve a range of speeds and pressures for different surface requirements.

There are no reviews yet