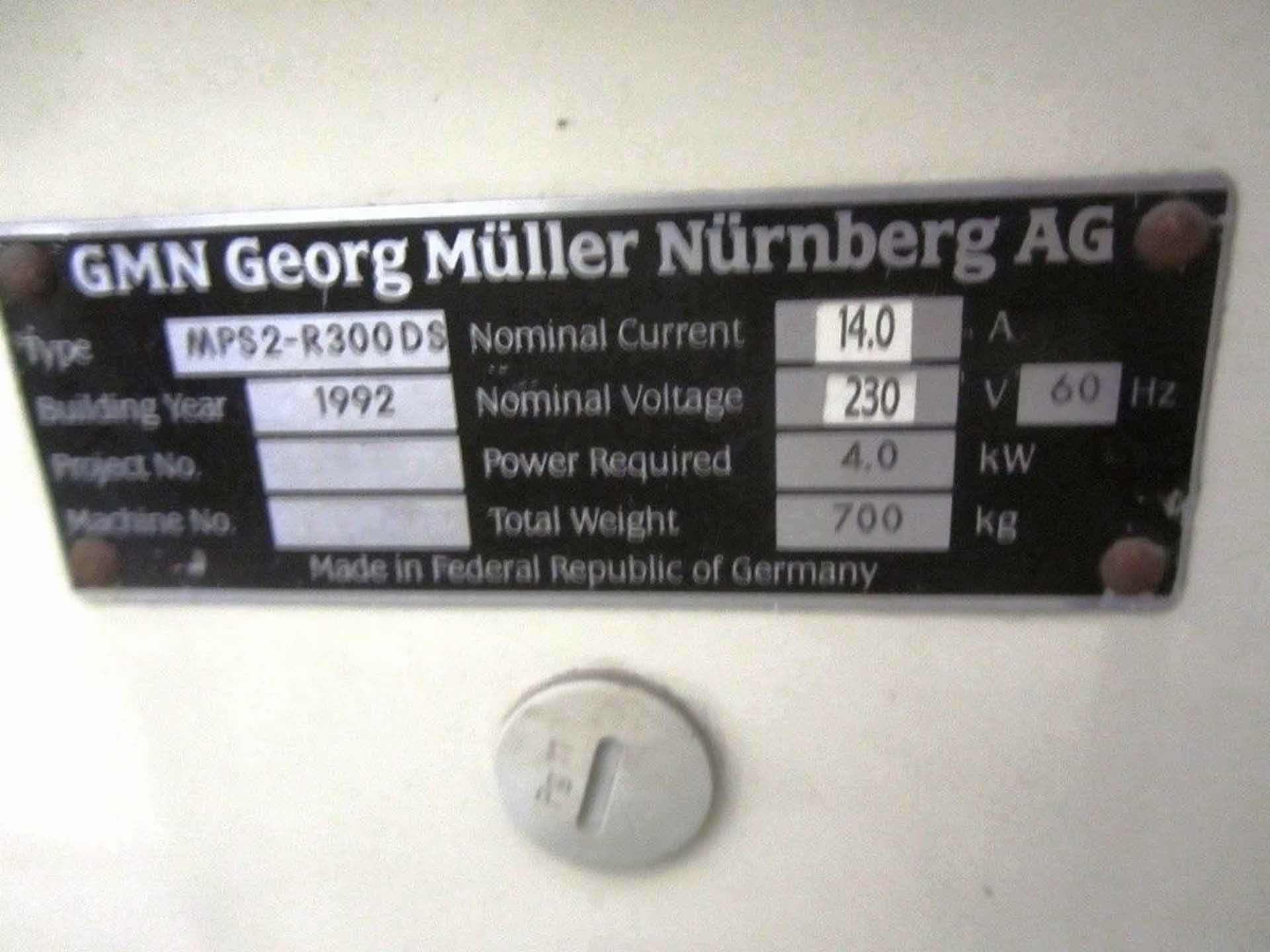

Used GMN MPS 2 R300 DS #9173026 for sale

URL successfully copied!

Tap to zoom

ID: 9173026

Wafer Size: 4"

Vintage: 1992

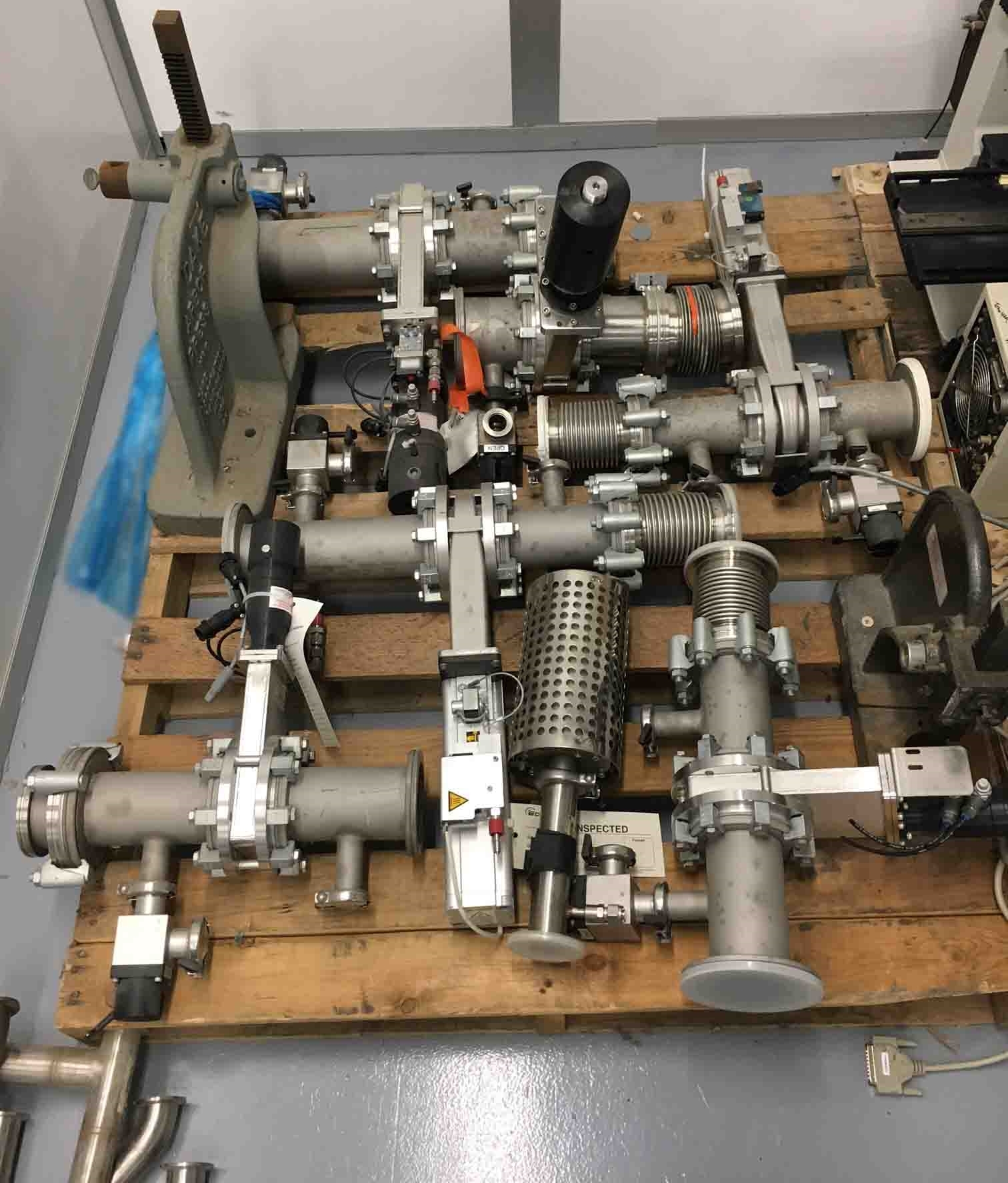

Surface grinder, 4"

Back grinding: Silicon wafers

Vacuum chuck

1992 vintage.

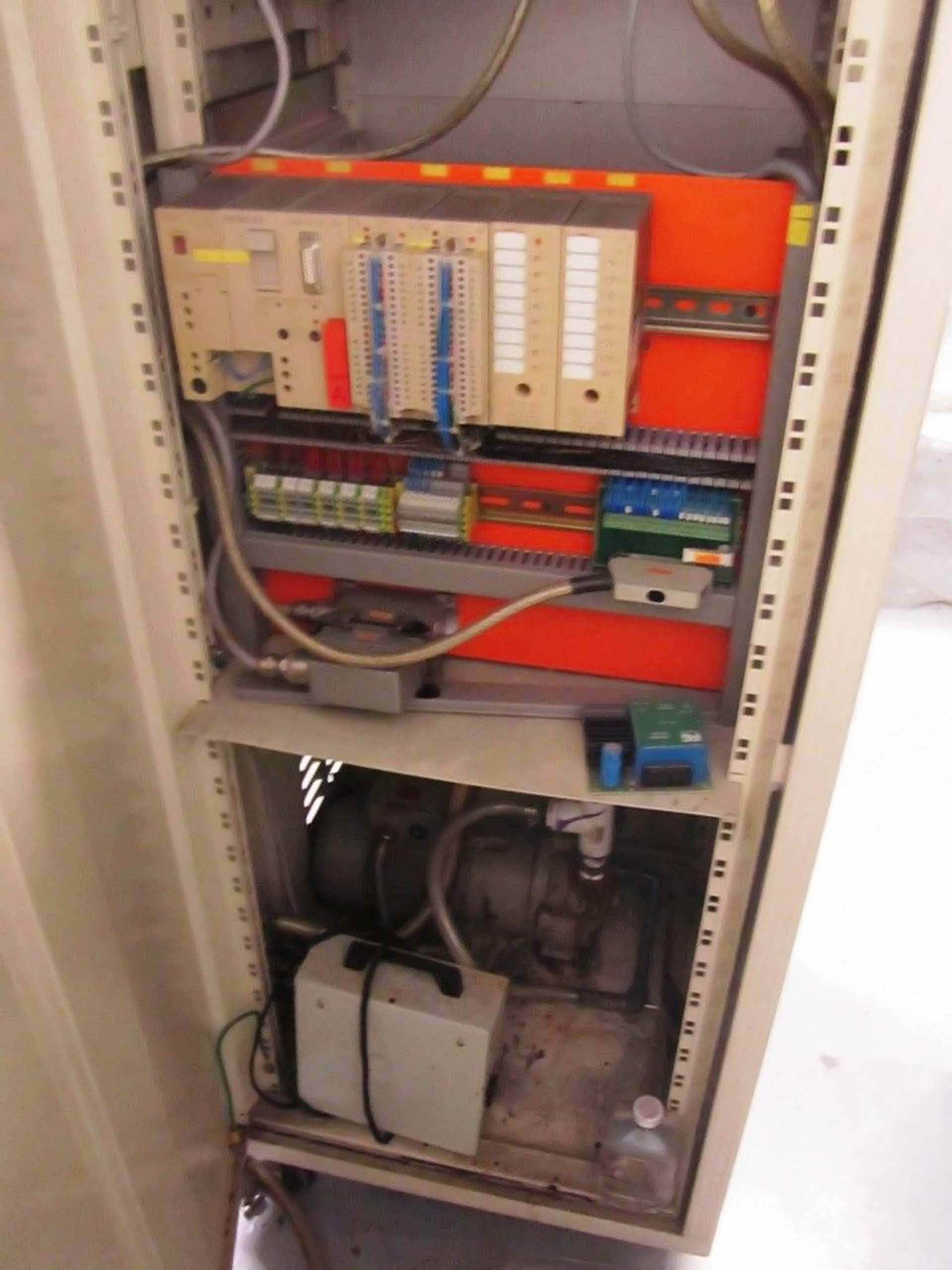

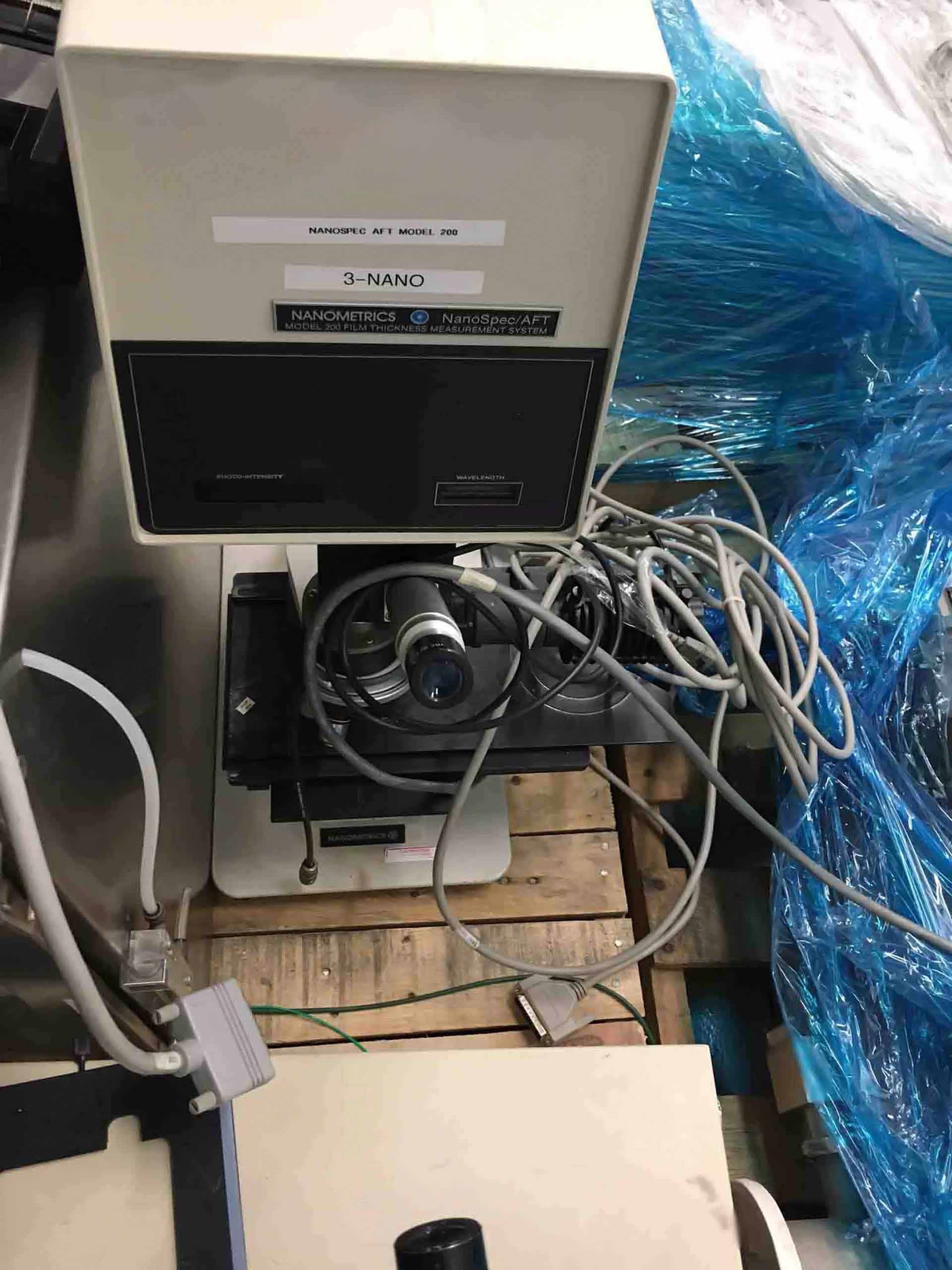

GMN MPS 2 R300 DS is a comprehensive polishing solution designed for the precision grinding, lapping, and polishing of various materials. It incorporates a highly efficient two-stage process, enabling the production of perfect surface finishes with impressive precision and repeatability. The equipment is engineered to provide fast and effective stock removal while maintaining extremely high levels of accuracy, repeatability, and quality control. GMN MPS 2 R300DS features a series of motor-driven grinding discs from which abrasive materials are fed. This allows for variations in speed and height of the abrasive media in order to achieve a desired surface finish. The feed rate of the abrasive media is adjustable and can be precisely controlled. Additionally, a separate downdraft table is integrated into the system and can be used to allow for the removal of dust, debris, and other byproducts of the grinding process. MPS 2 R 300 DS also includes clamp chambers and support systems that can be tailored to the exact demands of the individual application. Customizable platen systems allow for the grinding of wafers or larger materials with a thickness up to 0.6mm, and the grinding process can be monitored and adjusted with the advanced integrated control unit. MPS 2 R300 DS utilizes a variety of grinding and polishing techniques to ensure consistent reliable results. A wide range of optional grinding or polishing tools can be utilized with the machine to provide excellent machining and finishing of any material. A number of other features, such as a frequency-converted speed range, rotation angle indicator, and various safety interlocks are also included to ensure safe, efficient operation of the tool. In conclusion, GMN MPS 2 R 300 DS is an advanced precision grinding, lapping, and polishing asset designed to produce perfect surface finishes with excellent accuracy and performance. Its capabilities are further enhanced with a range of optional components allowing for a variety of grinding, lapping, and polishing techniques to be used, ensuring superior quality results.

There are no reviews yet