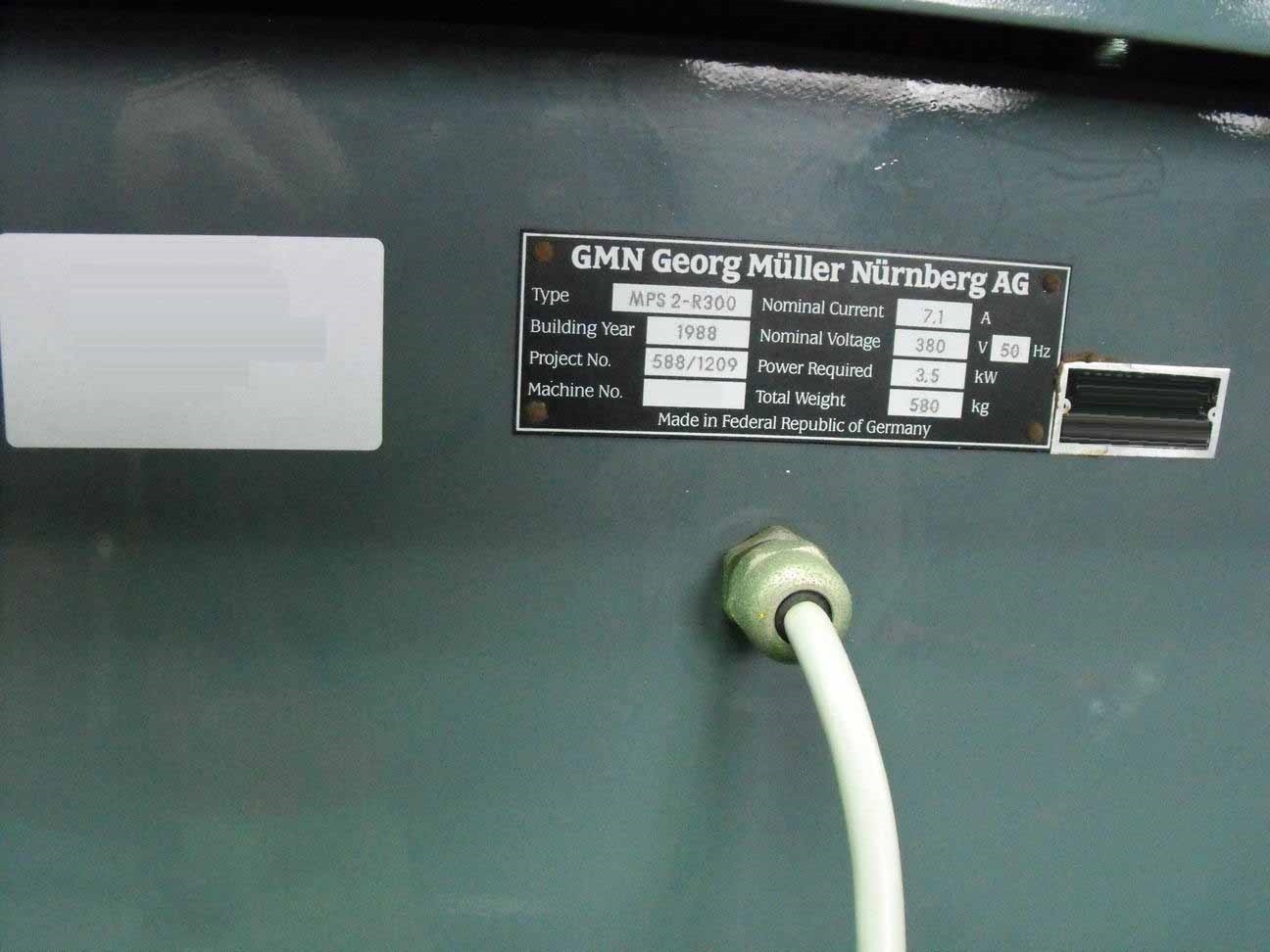

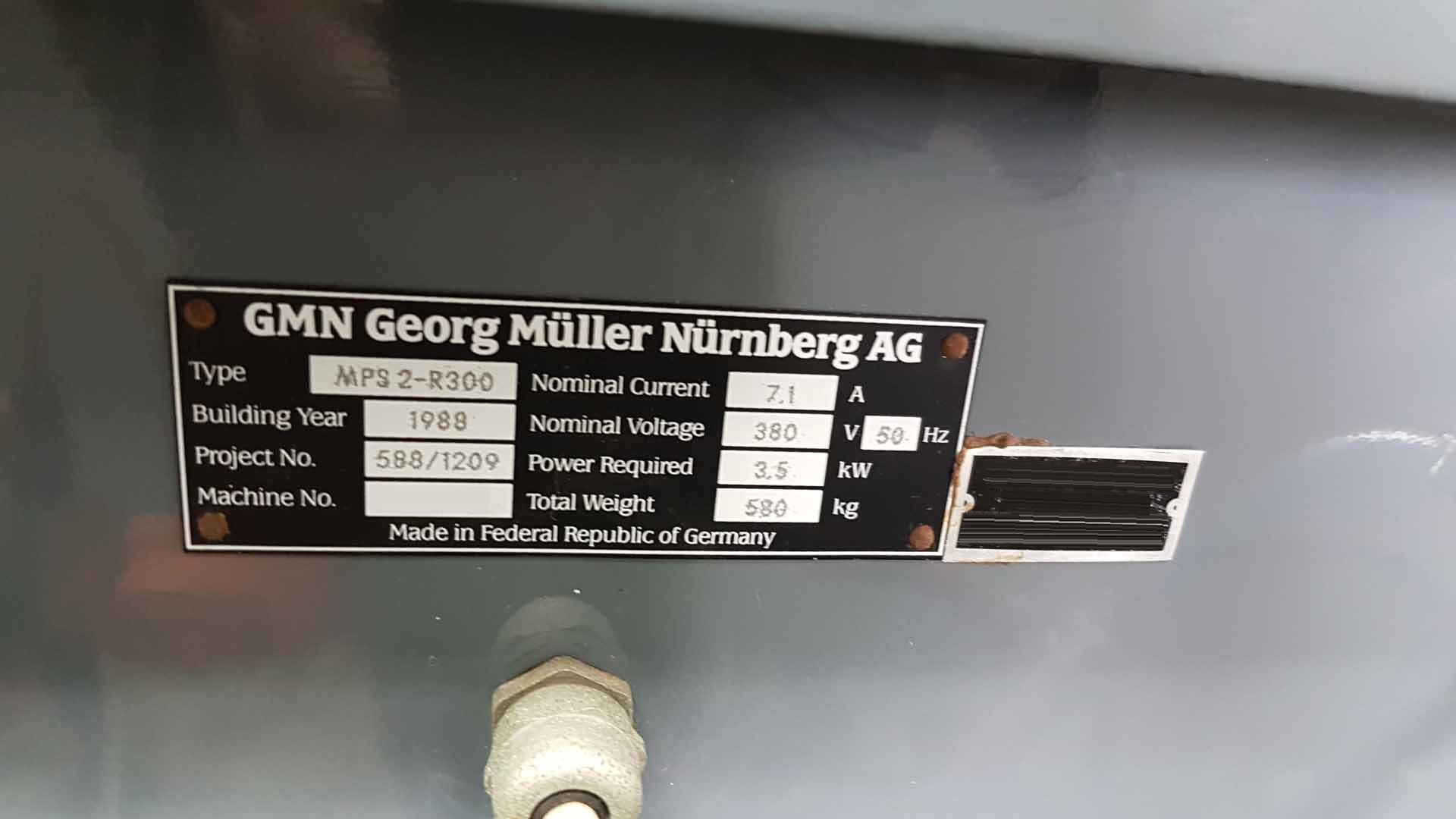

Used GMN MPS 2 R300 #9162225 for sale

URL successfully copied!

Tap to zoom

GMN MPS 2 R300 is a wafer grinding, lapping and polishing equipment used for applications in the semiconductor industry. The system provides excellent surface finishing and high-precision grinding of the wafer edges. The unit includes a robotic machine to precisely position the wafer on the grinding table for safe and accurate grinding. The tool also features a vacuum bed that holds the wafer securely in place and can be used for grinding, lapping and polishing large wafers. The asset has two grinding heads, each driven by a powerful motor that delivers up to 500 W of power to each head. This allows the user to grind and lap multiple wafers simultaneously and quickly. The model is equipped with adjustable pneumatic stops to stop the grinding disc in the exact position required. The grinding head has a high accuracy diamond grinding disc which allows the user to perform precise grinding on the wafer edges. The grinding head also features integrated compressed air cooling for optimal grinding performance. The equipment includes a lapping table for single sided and double sided lapping operations. The table is equipped with a high-precision lapping mechanism and is adjustable, allowing the user to adjust the lap angle and speed to suit the application. The system is also equipped with a polisher for polishing the wafer edges. The polisher is designed to achieve a high level of polishing to remove any roughness and improve the final edge profile. The unit is capable of grinding, lapping and polishing wafers up to 300 mm in diameter. The machine is also equipped with a high-resolution optical microscope that allows the user to inspect the wafer surface prior to final processing. This allows users to identify any surface defects before proceeding to the next stage. MPS 2 R300 is a reliable and efficient tool that can be used for a variety of wafer grinding, lapping and polishing applications. The asset offers high-precision and speed, making it ideal for any semiconductor fabrication process. The model is easy to use and can be quickly configured to suit the needs of the user.

There are no reviews yet