Used HITACHI 324 #9215070 for sale

URL successfully copied!

Tap to zoom

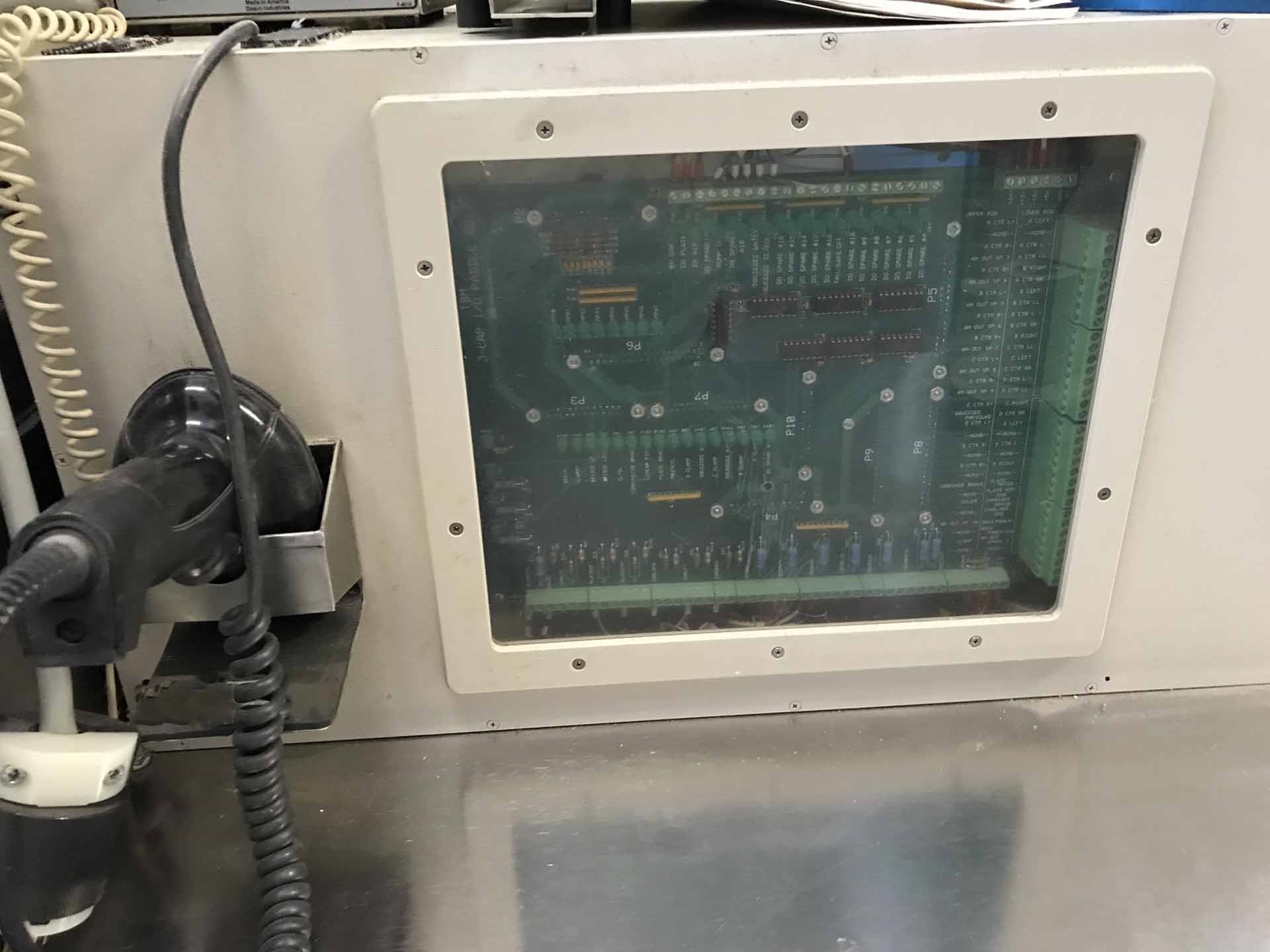

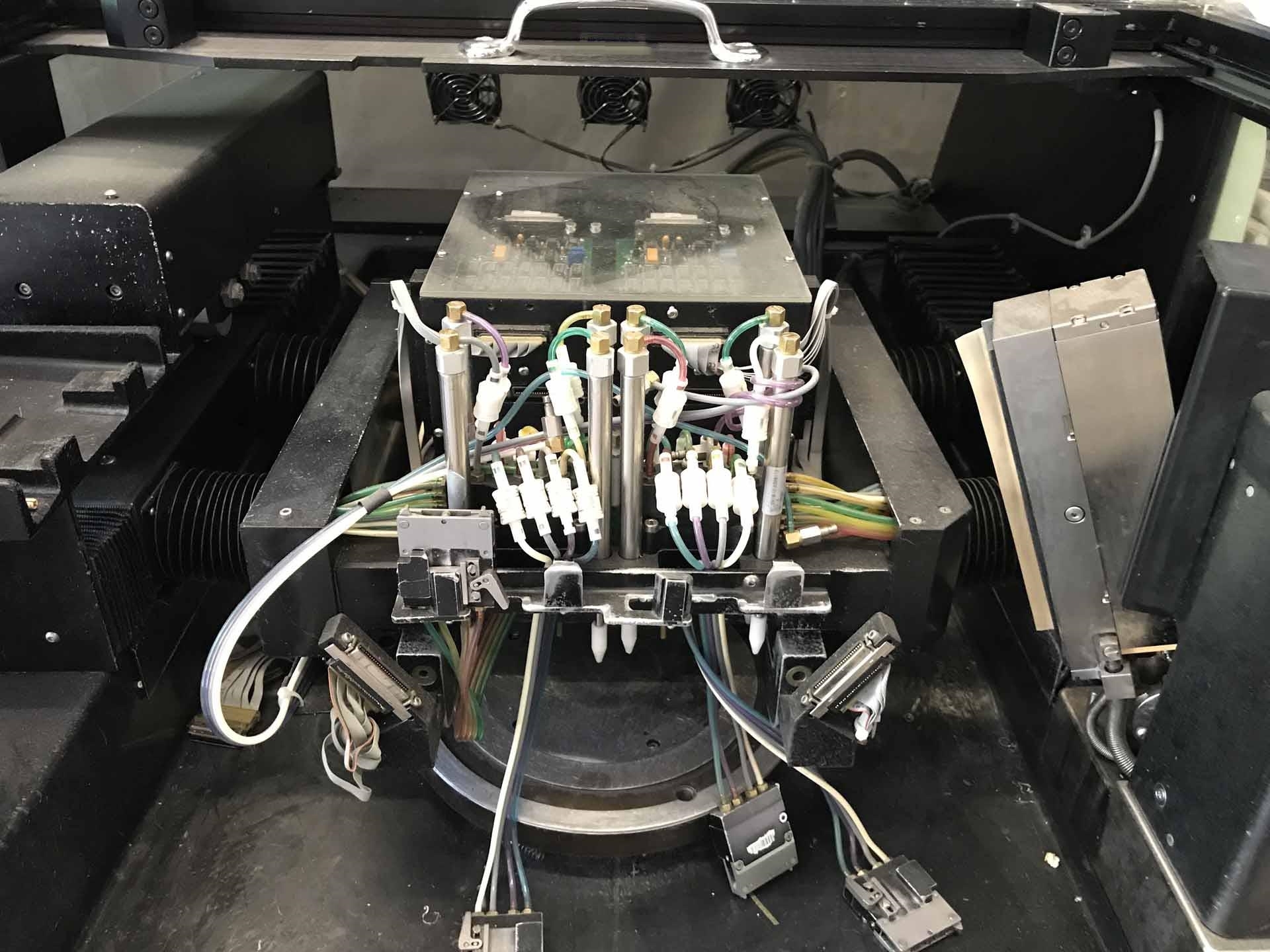

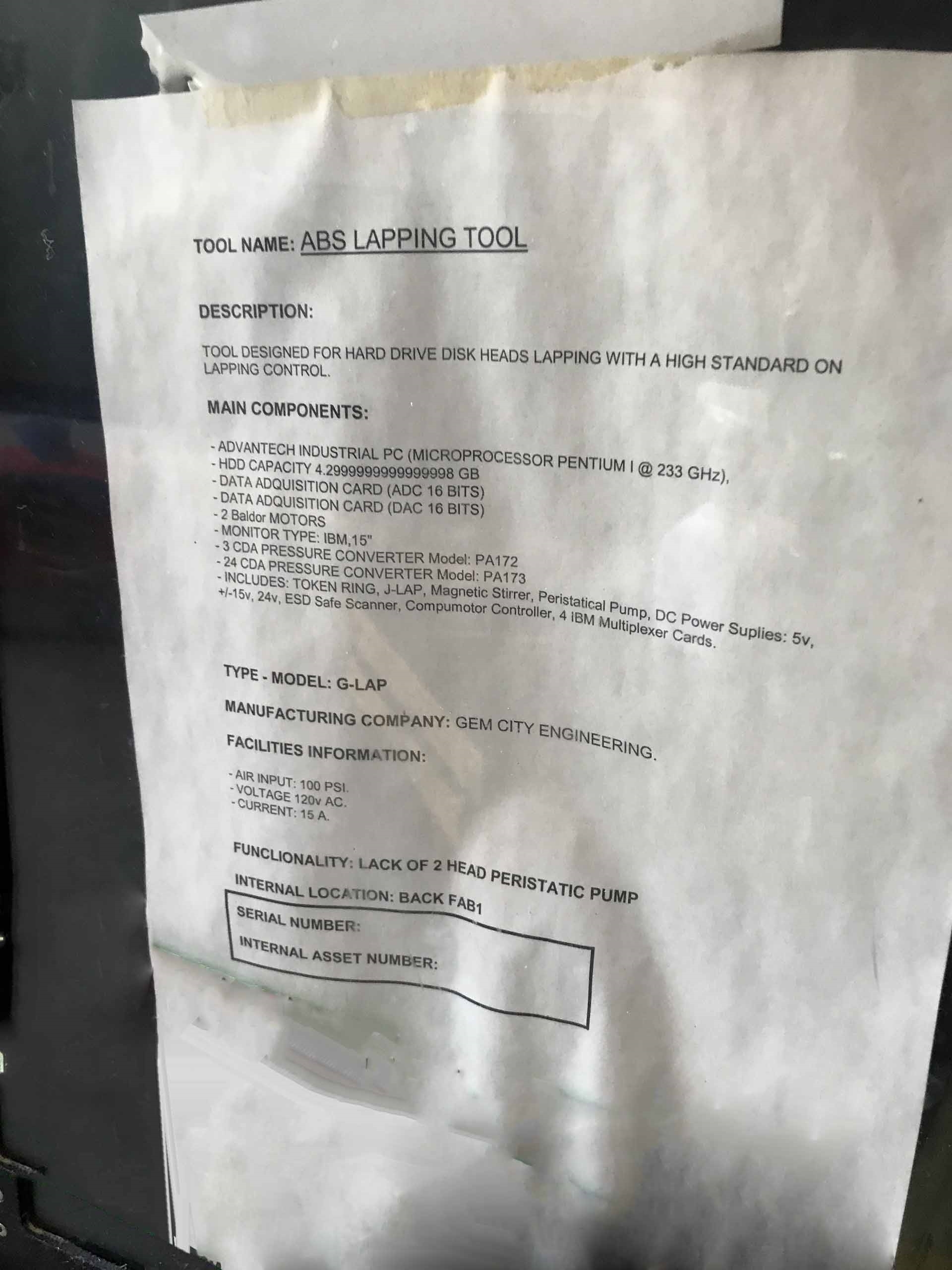

HITACHI 324 Wafer Grinding, Lapping and Polishing Equipment is a cost-effective automated process that enables manufacturers to create surfaces with high precision and uniformity. This system is ideal for process development, polishing and mirror surface application. This machine is suitable for applications such as integrated circuit polishing, precision optical parts, and contact lens manufacturing. 324 utilizes a unique four-station processing chamber to enable simultaneous grinding, lapping, and polishing processes. It uses planetary motion with a single-rail motion carriage for precise movements and can accommodate up to three wafers at a time. The unit is dust-proof and humidity-controlled to prevent potential contamination and damage. The working platform of HITACHI 324 is equipped with two position sensors and two force sensors, as well as an inspection microscope with a zoom lens and stage plate enabling apposite magnification of the sample surface. Additionally, the machine has an independent controller equipped with an 8-inch colored touch-panel. This model is suitable for setting parameters and monitoring the machine, as well as quick and easy programming of recipes. 324 is also capable of controlling a variety of materials and improves processing times with its linear frequency control. It also has a PC-based control unit which is equipped with graphical display software. This software can control all settings in real-time, displaying a host of parameters like pressure, speed, temperature, and pressure distribution. HITACHI 324 is equipped with multiple safety features such as temperature sensors, dual redundancy of air pressure controllers, and safety mechanisms on the grinding, lapping, and polishing heads to prevent unexpected tool malfunctions. The machine is also CE certified. In closing, 324 Wafer Grinding, Lapping and Polishing asset is an automatic process that provides high precision and uniformity enables manufacturers to create various features of the sample surface. This model is highly reliable, efficient and safe, making it ideal for applications such as integrated circuit polishing and contact lens manufacturing.

There are no reviews yet