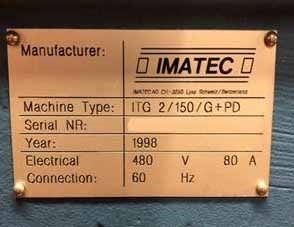

Used IMATEC ITG-2-150-G+PD #9216458 for sale

URL successfully copied!

Tap to zoom

ID: 9216458

Vintage: 1998

Through feed grinder

Conveyor belt: 150 mm (5.9”) Wide

Conveyor belt length: 4600mm

Includes:

Fixture wash station

Grinding wheel balancer

Cyclotron type CA21: Coolant paper filter (30 Micron) tank

Spindle speed of grinding wheel: 1750 RPM Maximum

Spindle motor power: 18.5 kW / 24.8 HP

Machine controller: PLC

ALLEN BRADLEY SLC 5/03 With operator panel

Grinding station:

Equipped with water cooled

Spindle motor: 25 kW & Fixed spindle speed

Grinding spindle size: Diameter 160 mm

With displacement: 200 mm

Pneumatic wheel wear detection system

Accuracy & stability: Four post die sets

(2) Grinding spindles:

Main spindle: Grinding

Second spindle: Brush deburring

De-burring station:

Equipped with variable spindle speed

De-burring wheels bolted to wheel flange

(2) Machine hoods:

Upper part: Mechanical movements and drive systems

Lower part: Grinding area

Upper hood: (3) Access doors

Includes:

Accessories with machine

Panel view 550 monochrome includes ALLEN BRADLEY diagnostics

Wet grinding includes:

Coolant distribution to several different areas:

Grinding wheel

Brush de-burring station

Belt cleaning both inner & outer side

Air nozzle with height adjustment system

Electrical drive motor

Control unit

Reduction valve

Permanent magnetic chuck: 150 mm x 1600 mm

With fixed down-hold

Leveling shoes includes for ITG:

4 Leveling shoes & anti-vibration elements

Height of shoes: 55 mm (Approximately)

Grinding wheel flange: 350 mm

With (10) holes for fixing bolts

Bolts and weights for balancing & spindle cooling unit included

Power supply: 480V, 80A, 60 Hz

1998 vintage.

IMATEC ITG-2-150-G+PD Wafer Grinding, Lapping and Polishing Equipment is designed to improve the efficiency of surface preparation applications. This compact, high-throughput system offers a great level of flexibility and cost-effectiveness, enabling users to prepare surfaces of different sizes and characteristics. The unit is equipped with a powerful grinding and polishing head, a wafer transporter machine, and a vibration-dampening platform. The grinding and polishing head has diamond wheels that allow for a precise and repeatable grinding and polishing process. The tool also includes a vacuum chuck to securely hold wafers during lapping and polishing. The wafer transporter asset is designed to quickly transfer wafers from the head to the work surface, while the vibration-dampening platform helps to ensure precise and repeatable results. The model is equipped with a servo-driven control equipment that helps to ensure the optimal speed and accuracy for each operation. The grinding, lapping and polishing process is completely automated, which drastically reduces operator fatigue. The system's user interface is intuitive and easy to use, allowing for optimal process control and parameters adjustment according to the nature of the material and the surface to be prepared. IMATEC ITG-2-150-G+PD is also designed to be integrated with many other wafer preparation processes. It is capable of adjusting its speed automatically to match the cycling rate of a CMP unit, allowing for a fully integrated manufacturing line. The machine also provides an accurate and repeatable finish in the appropriate range of grit size. This helps to facilitate the manufacturing process and improve throughput. Overall, IMATEC ITG-2-150-G+PD offers a great level of flexibility and performance for wafer grinding, lapping, and polishing applications. Its design allows for high-precision machining with reduced operator fatigue and improved product quality. The tool is perfect for users who need a cost-efficient and reliable asset that can deliver repeatable and accurate results.

There are no reviews yet