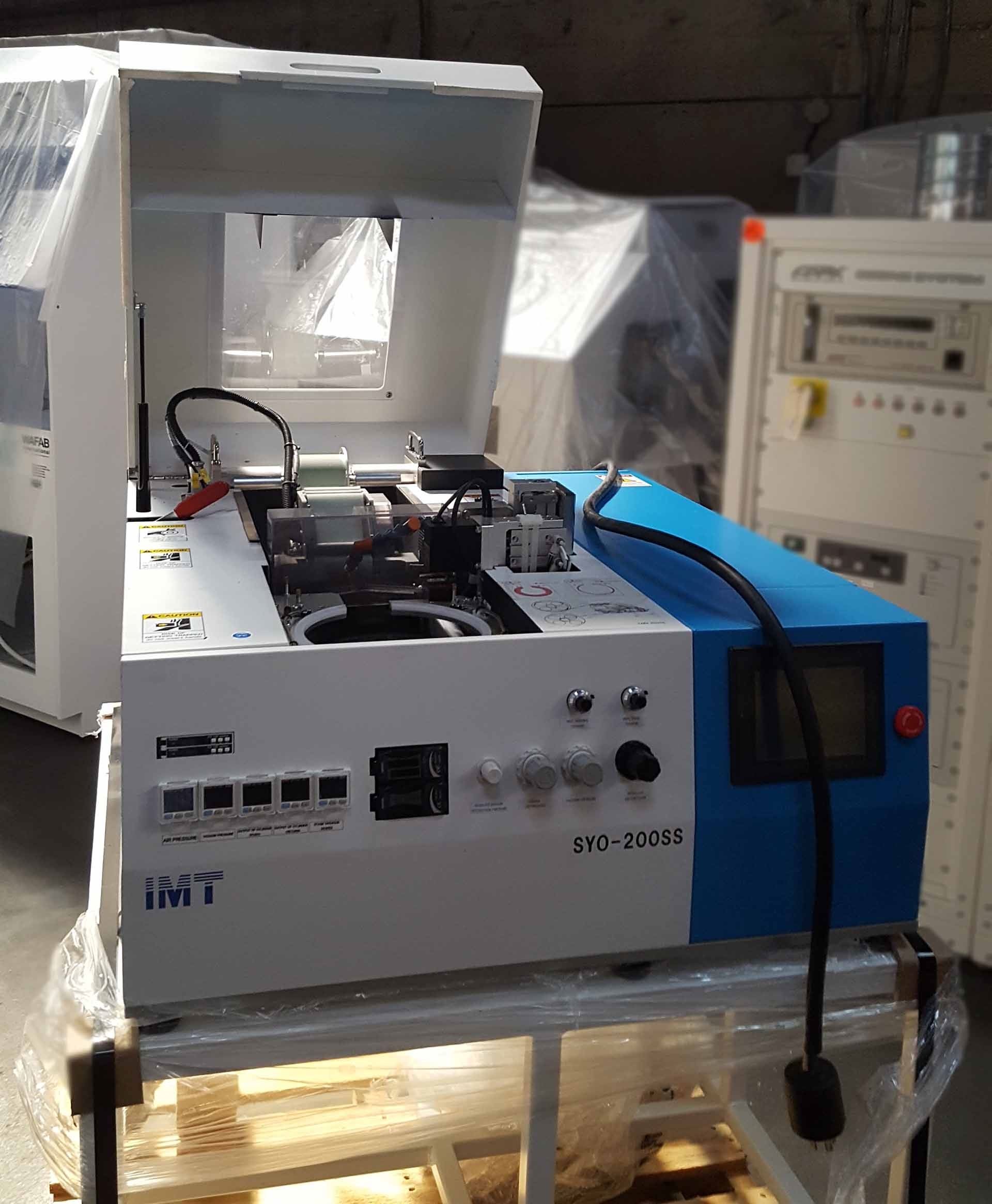

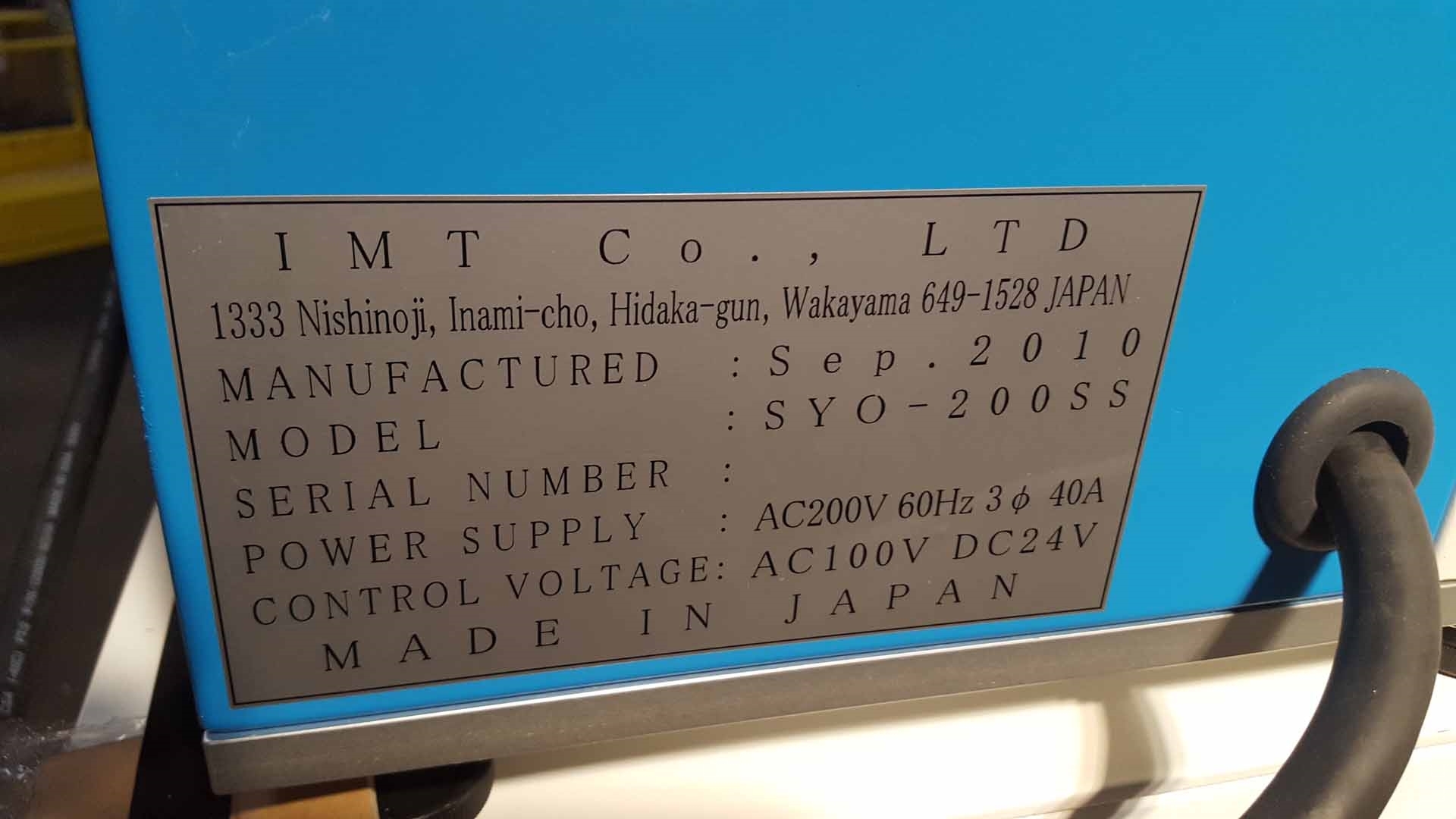

Used IMT SYO-200SS #9223029 for sale

URL successfully copied!

Tap to zoom

ID: 9223029

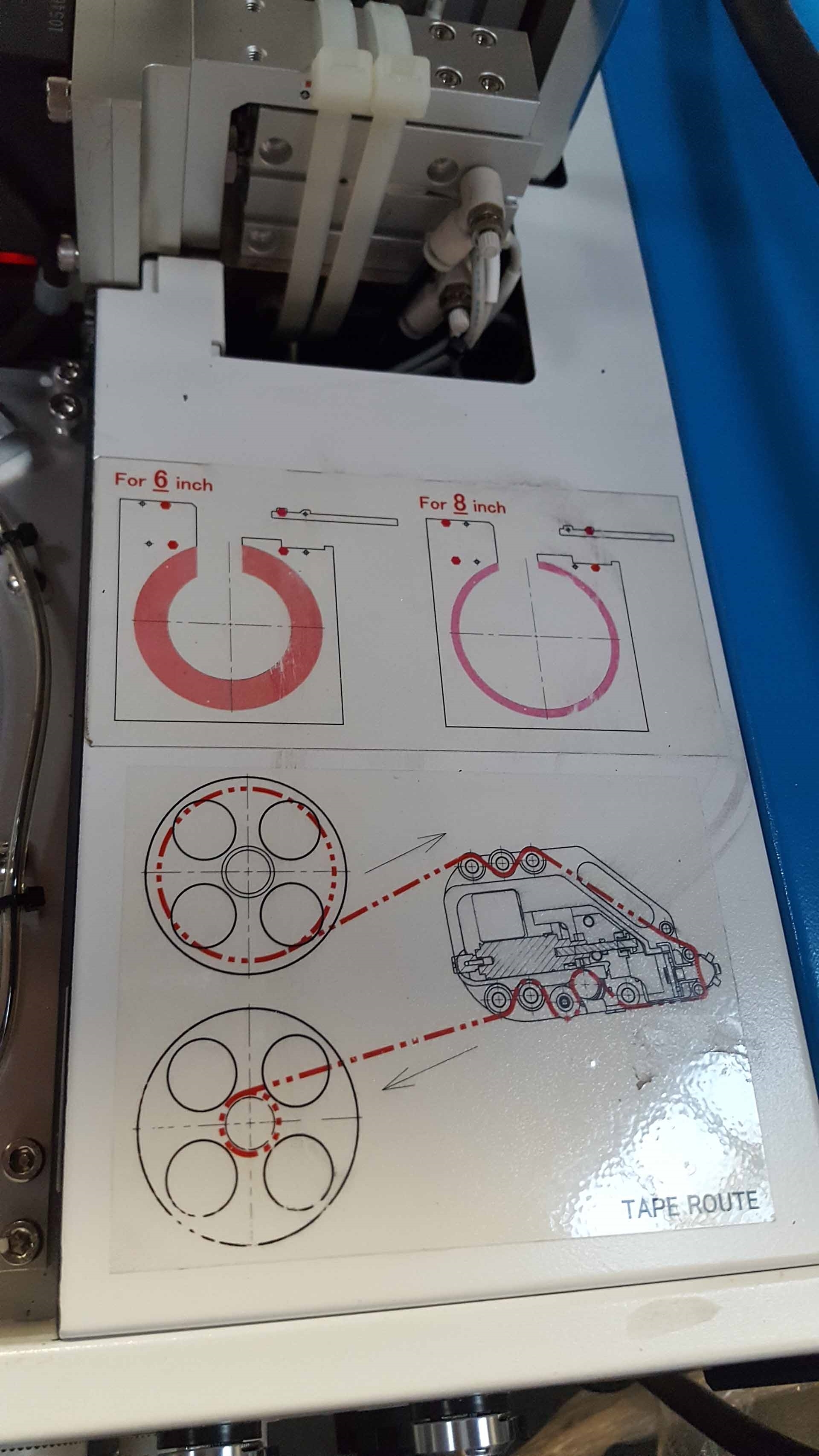

Wafer Size: 2"-6"

Vintage: 2010

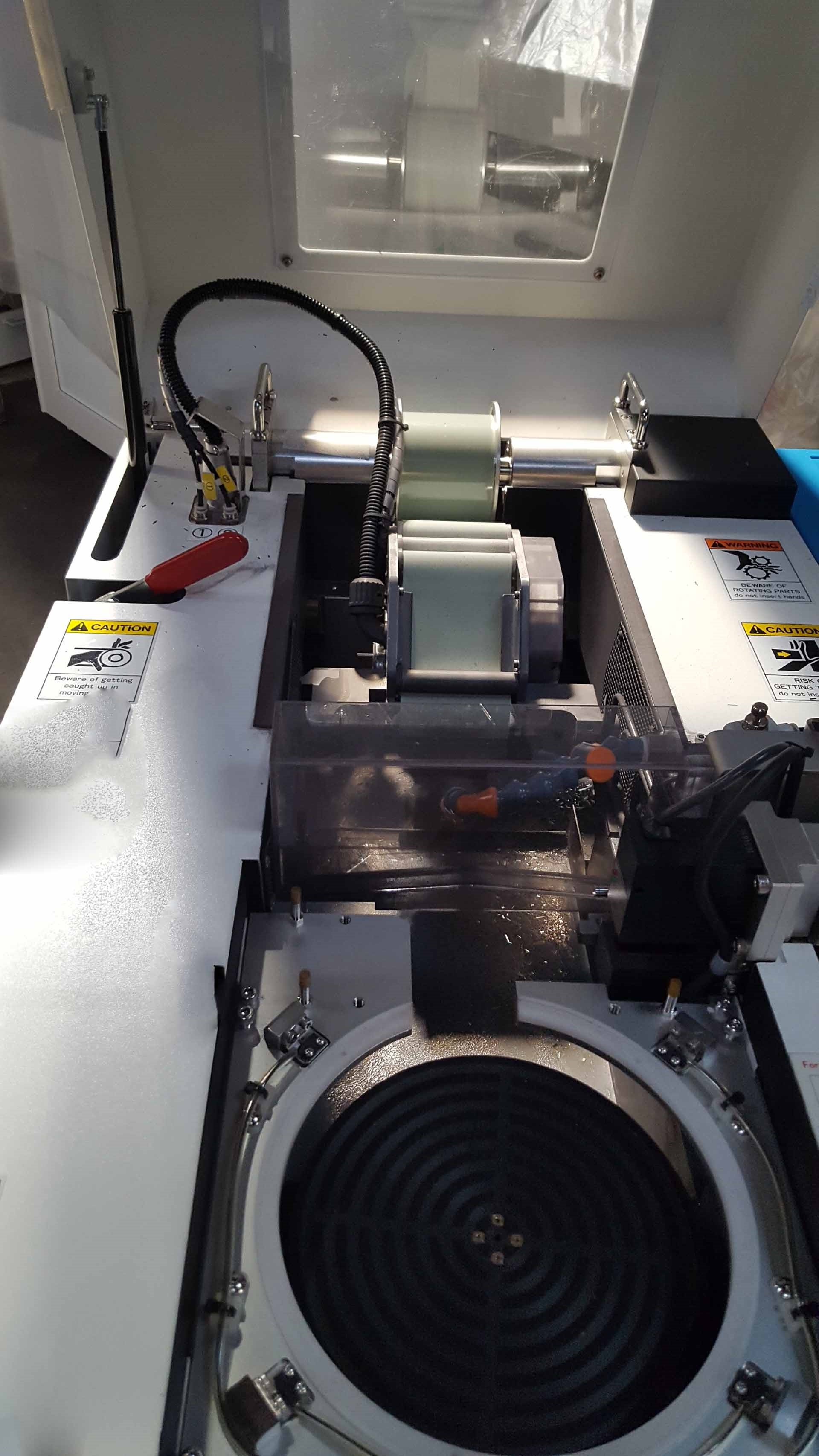

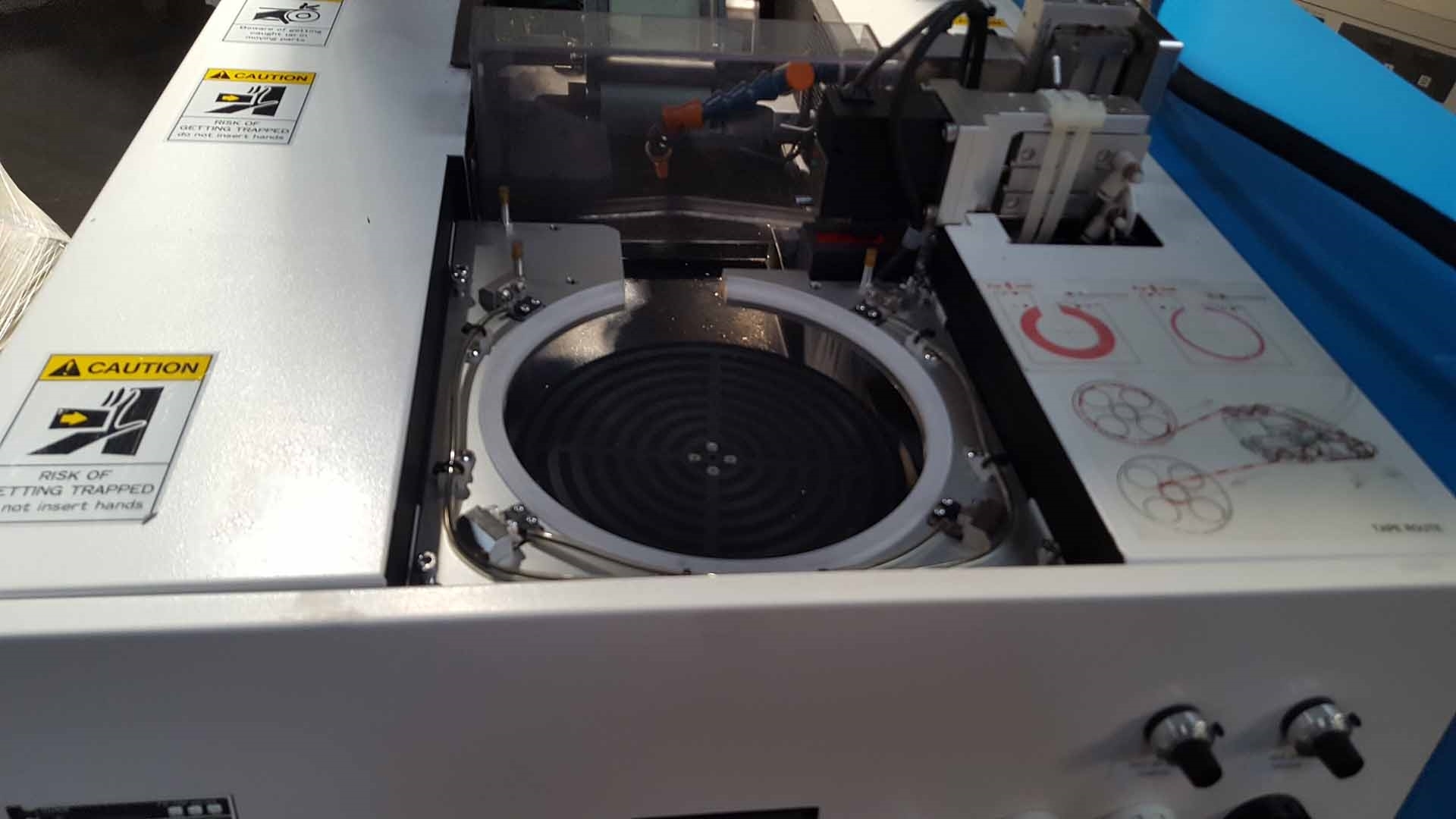

Polishing system, 2"-6"

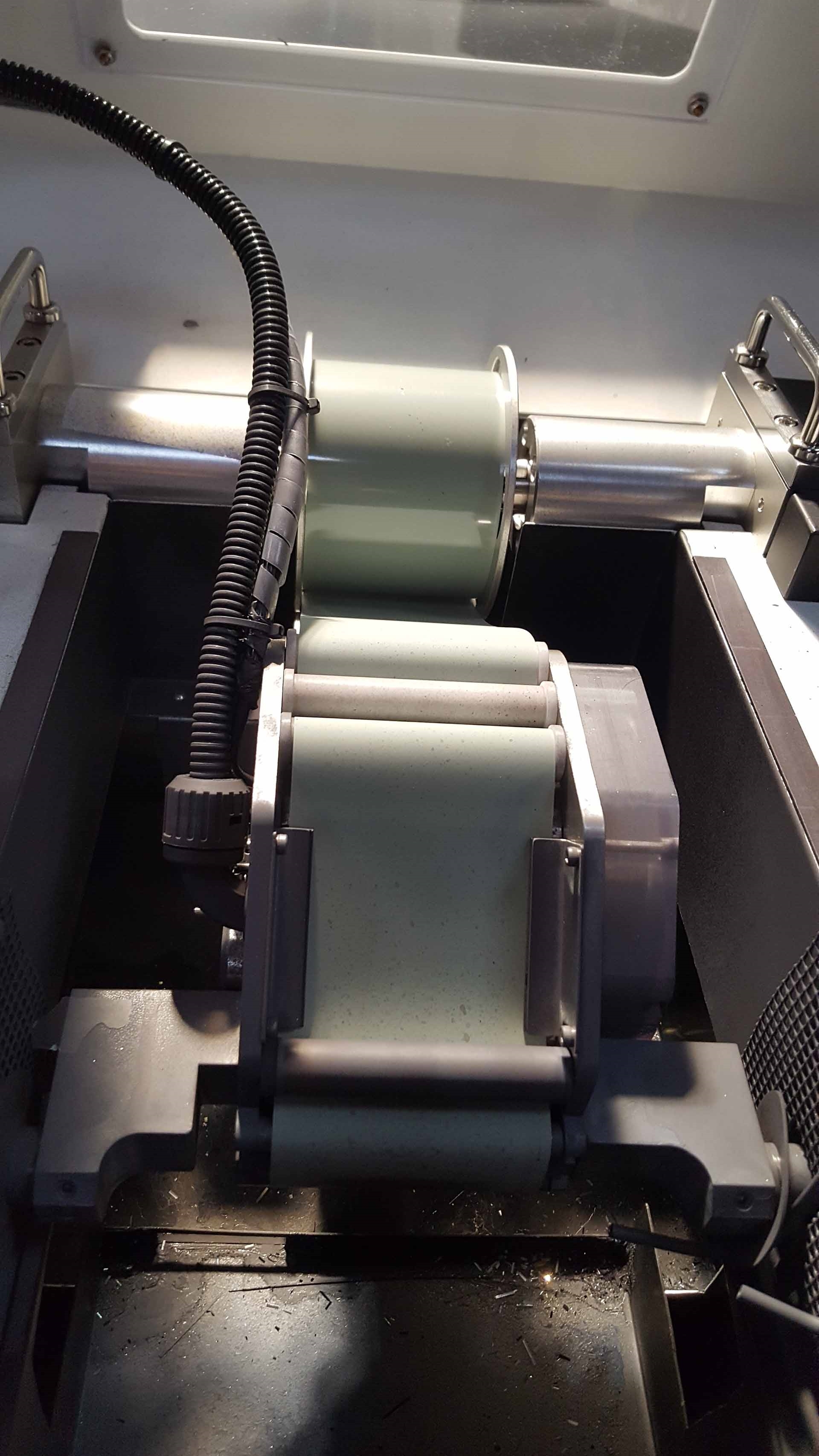

Type: Tape / Belt

Polishing tape width, 3"

Tape feed speed: 10 to 200 mm/min

Spindle rotation speed: 1000 rpm @ Polishing / 2000 rpm @ Drying

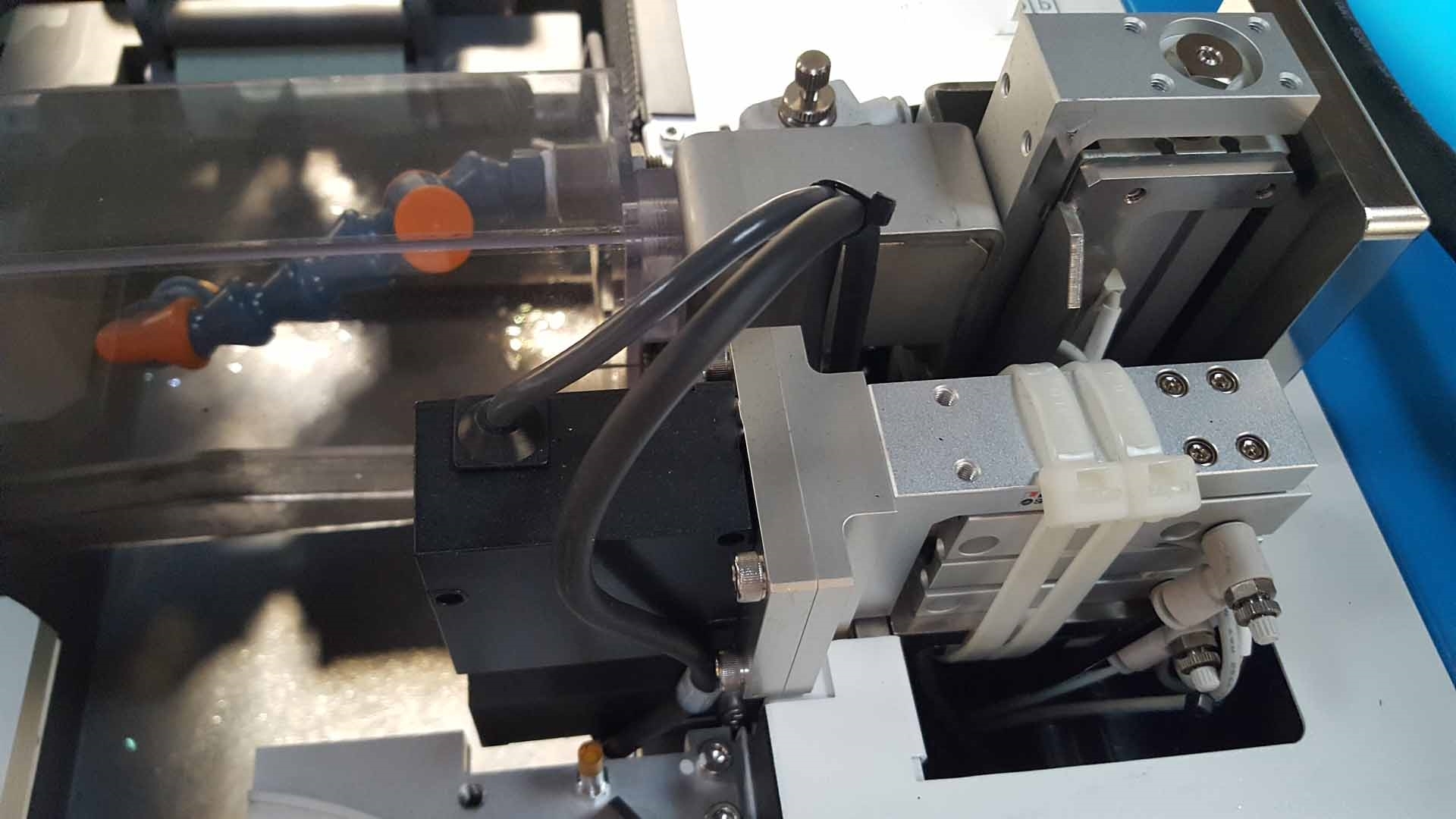

Head oscillation speed: 60 - 300 rpm

Head tilt angle: +68°, -10°

Control voltage: AC 100 V, DC 24 V

Power supply: 200 VAC, 40 A, 60 Hz, 3 Phase

2010 vintage.

IMT SYO-200SS wafer grinding, lapping & polishing equipment is a cutting edge tool for the precision processing of wafers, designed to provide accurate and reliable results every time. The system utilizes an integrated spindle-based grinding and lapping process for accurate and repeatable performance. An intuitive user interface makes setting up and running the unit simple and easy. The machine is built around a powerful spindle motor, able to rotate up to 8,000 rpm, allowing for a variety of grinding operations and providing optimal flexibility for different materials. The spindle also features a mechanical drive tool that offers precise control and ensures repeatable results. An integrated load/unload mechanism lets staff quickly and accurately load and unload wafers from the asset at any angle, and also prevents the wafers from tilting during the process. SYO-200SS model also boasts a wide range of lapping and polishing parameters, including multiple single-sided and double-sided configurations and a variety of feed rate and dwell time settings. This ensures that each wafer is processed in accordance with the required specifications" The stand-alone grinding station is controlled by a touchscreen user interface, which enables the user to quickly program and configure the equipment for the desired job. The system comes with a variety of features, such as data management capabilities, job scheduling, and quality control functions. The integrated Windows® operating unit gives the user access to powerful commands and the ability to customize settings. IMT SYO-200SS offers a modular design and flexibility, making it an ideal wafer processing solution for applications such as spintronics, MEMS, optics, data storage devices, and microelectronics. It is also integrated with a vacuum machine, which evacuates the air during the grinding and polishing process ensuring a dust and particle free environment. With its built-in safety features, the user does not require a special operator certificate in order to set up and run the machine. Overall, SYO-200SS is a robust, dependable, and reliable tool providing superior performance for wafer grinding, lapping, and polishing applications. It is easy to install and use, and it also offers flexibility to accommodate a variety of processes.

There are no reviews yet