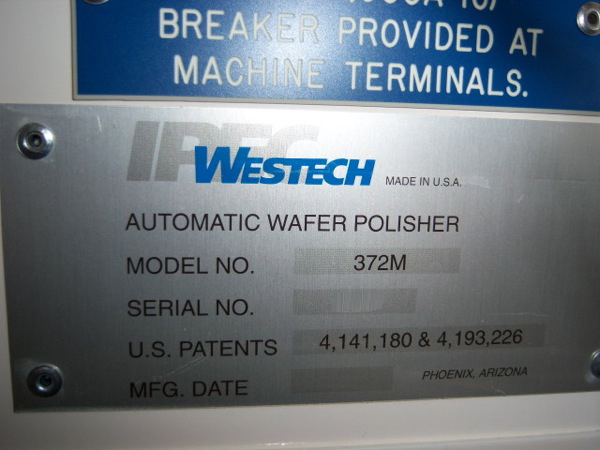

Used IPEC / WESTECH / SPEEDFAM 372M #155037 for sale

URL successfully copied!

Tap to zoom

ID: 155037

Wafer Size: 8"

ILD CMP Oxide/Poly Silicon/STI systems, 8"

Specifications:

Model 372 polisher mainframe

Novascan Model 210 thickness measurement system

32 bit Hardware Upgrade (Adtron Thincard system)

SECS I / II Host Computer Interface

Floppy Drive

Printer / Terminal Interface Software

Software-Controlled Process Variables with Hi/Low Limits

Dual Sensor Loadcup

SFI Load Station Sensor RFK

Gaard Arm pad conditioner

7.5 hp Final Platen Drive System

750 lb. Down-Force Polisher Arm

Closed-Loop Load Cell Down-Force Control

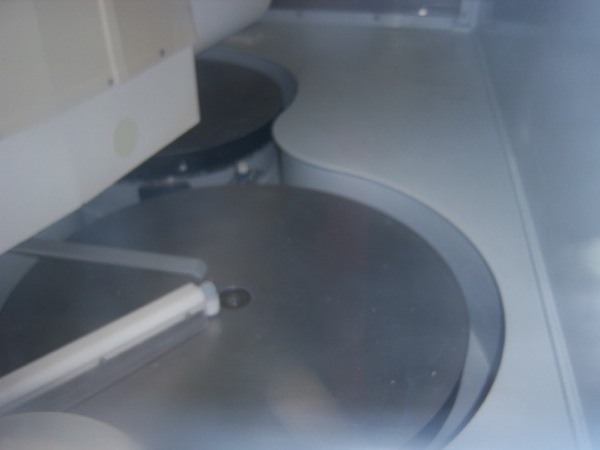

High-Pressure Primary Polish Station

TUFRAM-Coated Platen, 60 psi rating

Final Polish Station

TUFRAM-Coated Platen

1000 mL Flow Slurry Pumps (2 Primary - 2 Final)

Wafer Carrier Speeds (10-125 rpm)

Platen Speed (10-175 rpm)

Head Clean Station Quick-Dump Rinse Unit

Clean Station Float Sensor

Capacitance Level Sensor for Polish Tub

Slurry Manifold - BECO Valves

DI Manifold - BECO Valves

PRi compatible environmental hood

Moisture Sensor in Fluids Cabinet and System Base Interfaced

Process Chilled Water Temp Gauges and Flow Meters

Fluids Cabinet Exhaust

AWN Interface - Underneath

Mushroom-style Emergency Machine Off (EMO) Buttons

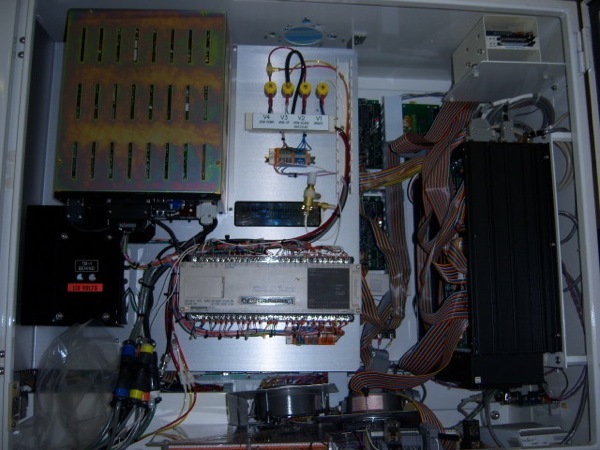

Electrical Cabinet

Heat-treated wood

Currently barrier bagged and crated.

IPEC / WESTECH / SPEEDFAM 372M is a wafer grinding, lapping, and polishing equipment designed for use in semiconductor wafer processing. The machine utilizes a three-axis (x, y, z) stage with a variable speed motor to produce uniform grinding and polishing results. It is designed for use in the production of both discrete and continuous wafers, with a maximum wafer size of 3.2" diameter. The grinding, lapping, and polishing system has a number of advanced features designed to ensure accuracy and productivity. It is equipped with a highly precise 3-axis DC motor-driven stage, along with a stepper motor drive, to ensure accurate and consistent grinding. The unit has a microprocessor-controlled grinding & lapping cycle with options for radius grinding, sheet grinding, and wafer grinding. It also features an automatic wafer loading machine along with a choice of abrasive discs for each operation. In addition to its grind, lap and polish cycle, the tool also has an auto-reverse feature that can be activated to help prevent materials from sticking to the grinding media. It also has an optional touch sensing feature which monitors asset temperature and pressure parameters to ensure consistent results. This feature also helps to reduce particle buildup as it prevents high-speed grinding cycles. For added safety, the model is equipped with a variety of protection features. These include a built-in emergency stop equipment, an overpressure valve, and a total run time function, allowing the user to monitor the total number of runs for each grinding operation. The system also features weight-sensing safety triggers which shut the machine off if too much weight is placed on the grinding plate. In addition, it has a chip tray and an insulated cover guard to prevent debris from being released into the environment. In conclusion, IPEC 372M is a robust wafer grinding, lapping and polishing unit, built with precision and safety in mind. Equipped with a variety of features, it is designed to improve the consistency and repeatability of grinding operations while providing added protection and precision.

There are no reviews yet