Used IPEC / WESTECH / SPEEDFAM Avanti 472 #60082 for sale

URL successfully copied!

Tap to zoom

ID: 60082

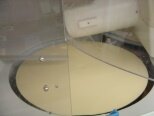

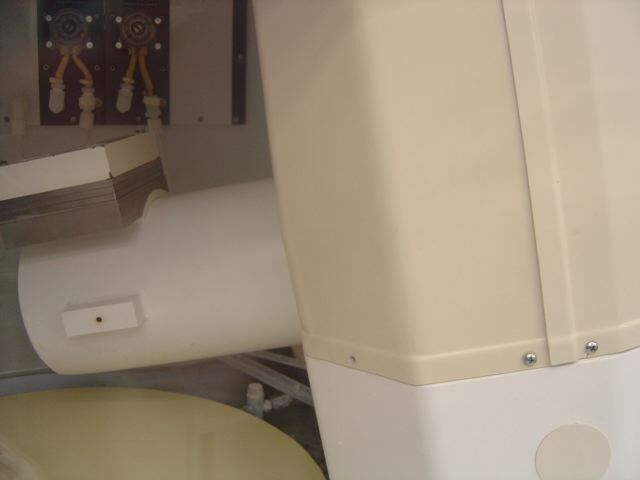

Wafer Size: 4"-8"

Chemical Mechanical Polisher (CMP), 4"-8"

Automatic loading / Unloading

DI Water:

Peak flow: 12 GPM (45.4 l/min)

Average flow: 6 GPM (22.7 l/min)

Pressure: 25 - 30 PSI

Chilled water:

Peak flow: 5 GPM (18.9 l/min)

Compressed air:

Peak flow: 6 SCFM (170 SLM)

Nitrogen:

Peak flow: 10 SCFM (283 SLM)

Power supply: 208-380 V, 460 VAC, 3 Phase, 50/60 Hz.

IPEC / WESTECH / SPEEDFAM Avanti 472 is a state-of-the-art wafer grinding, lapping and polishing system. The 472 is specifically designed for use with semiconductor substrates, and offers superior grinding, lapping, and polishing capabilities. The 472 is the latest version of the Avanti series and offers the most modern in wafer grinding and polishing technology. IPEC Avanti 472 consists of an adjustable dual-arm gantry that houses a twin spindle grinding, lapping, and polishing system. Equipped with a 40mm diameter platter and a 200mm table, the 472 provides precision material removal and planarization, while maintaining micron accuracy across the wafer surface. Multiple platters can be used simultaneously to increase throughput, and the patented Planetary Motion of the gantry improves vertical separation capability, providing a superior quality finish. The 472 uses a modular design for quicker integration and setup, and it is equipped with touch screen controls for simplified user interface. Integrated process quality control is managed using software, including advanced process monitoring and automated diagnostic servicing. The 472 is also equipped with integrated safety sensors for added operator protection. The 472 features a host of rotating and fixed spindles. High speed rotation spindles offer optimum speed flexibility, while programming-controlled spindles improve accuracy and repeatability. Diamond abrasive grinding disks are used to achieve an exceptionally flat surface, while an additional abrasive system is used to remove thin layers of material with greater precision. Automated sealing systems, environmental chambers, and a variety of tools are also available, allowing for processing of virtually any material. The 472 offers versatility and precision for a wide range of wafer grinding, lapping, and polishing needs. Its modular design makes integration and maintenance simpler than ever, and its automated controls ensure reliable, high-quality results each and every time. The 472 is the pinnacle of wafer grinding, lapping and polishing technology, offering the highest quality end-product and process reliability in the industry.

There are no reviews yet