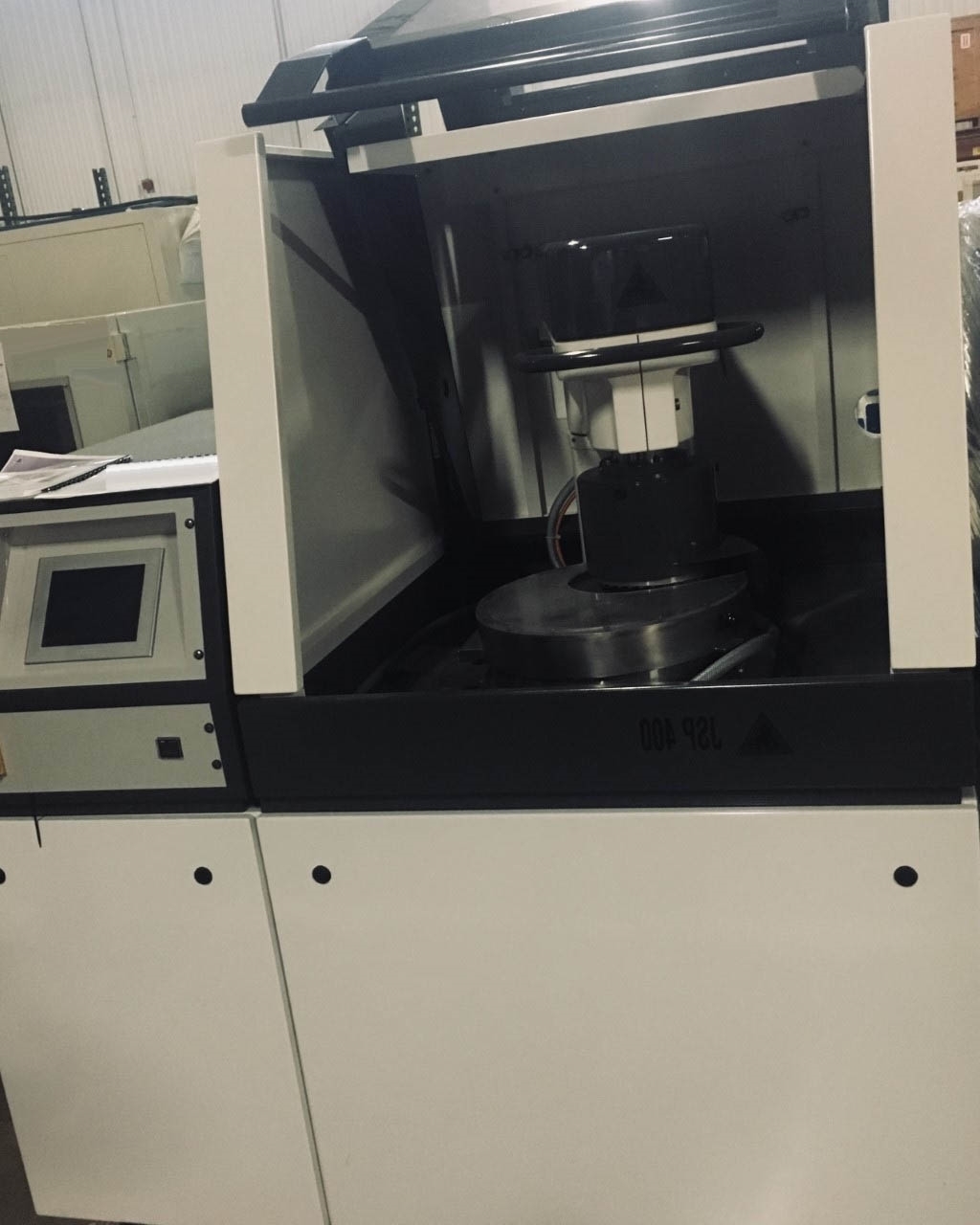

Used JSP / G&N MPS-2R-400D #9262593 for sale

URL successfully copied!

Tap to zoom

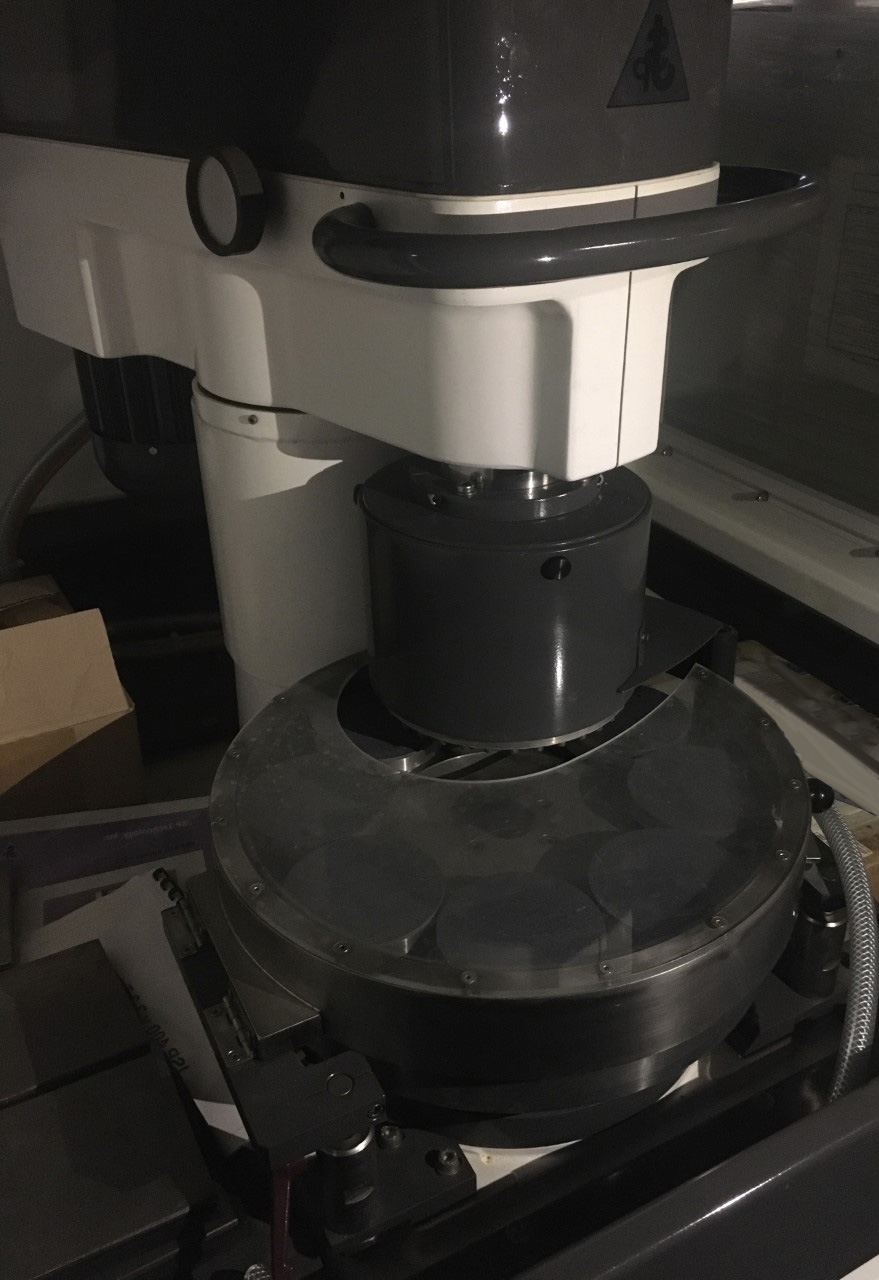

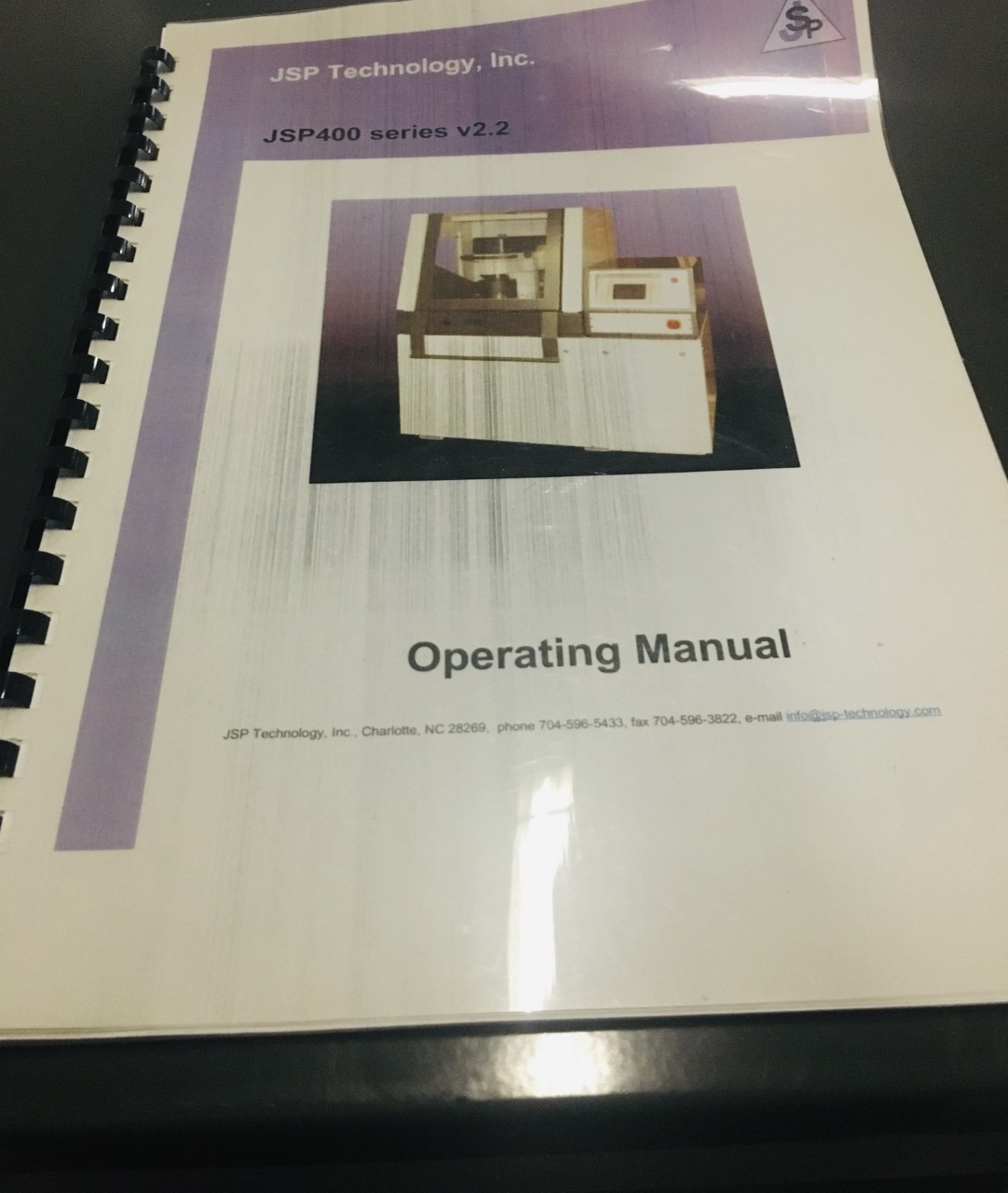

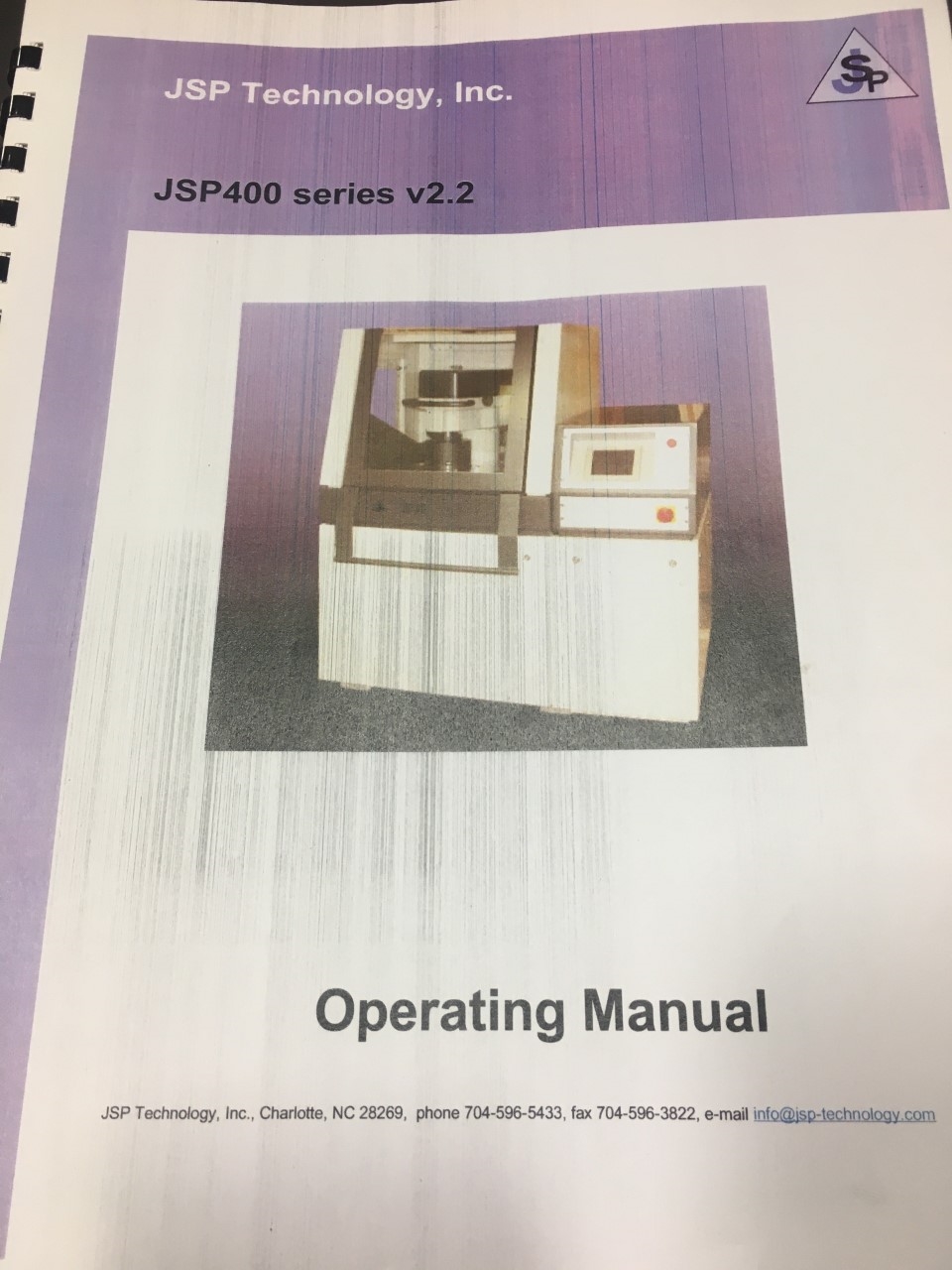

JSP / G&N MPS-2R-400D is a versatile wafer grinding, lapping and polishing equipment, designed for today's high-precision wafer processing. This state-of-the-art system features precision engineered components to ensure reliable operation and quality results. The unit offers a full range of grinding, lapping and polishing capabilities with adjustable speed motors and inverters, allowing for engineered speeds and power ranges to meet a variety of requirements. The high-precision robotic arm can be easily programmed for accurate and efficient wafer grinding, lapping and polishing, and the machine is equipped with superb digital controls for precise and repeatable process parameters. The machine is constructed of rigid stainless steel for robust operation, and each machining station is equipped with gas-cooled or air-cooled alternatives to help maintain ideal machining temperatures. The machine also features a multi-head spindle grinding head, allowing for multiple grinding configurations. In addition, the tool is equipped with a fully automated wet cleaning asset and user-adjustable pressure/flow specifications, allowing for superior lapping results. The integrated dual opto-electronic cams can track the surface profile of wafers during machining, ensuring precise and uniform operation. The modular design of JSP MPS-2R-400D allows for easy integration into existing wafer processing lines, as well as a host of additional configurations and capabilities. With a smaller footprint, the model requires minimal floor space and an efficient setup. Its variable speed controllers offer a range of speeds, from 0 to 10,000 rpm, for the most precise operations and process results. G&N MPS-2R-400D wafer grinding, lapping and polishing equipment offers optimal performance and repeatable results for today's most demanding wafer processing industries. With its rugged construction, precise digital controls and advanced machining capabilities, the system is an excellent choice for a reliable and efficient wafer processing solution.

There are no reviews yet