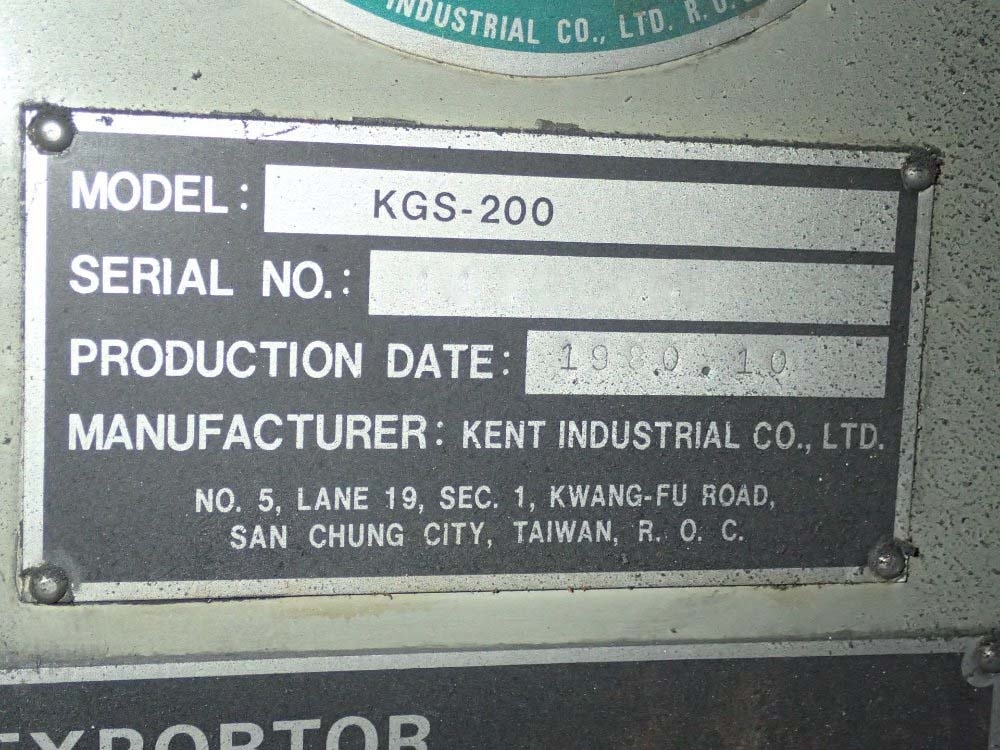

Used KENT KGS-200 #9209181 for sale

URL successfully copied!

Tap to zoom

KENT KGS-200 is a high performance wafer grinding, lapping and polishing equipment. Ideal for ultra precision applications from single wedge bonding to laser trimming to hard-wearing medical components, KGS-200 is designed to meet the most exacting requirements. The system is equipped with a permanent magnet spindle and power supply, capable of maintaining a rotational speed of up to 6,000 RPM. This provides an ideal platform for grinding, lapping, and polishing with 0.1-micron accuracy across the entire range of application requirements. The high-precision positioning and repeatability of KENT KGS-200's two-axis linear frame make it the perfect choice for lithography as well as for applications that require precise alignment and ultra-smooth finish. With a broad range of options, the unit is capable of processing a variety of materials, from traditional silicon wafers to copper, gold, and other exotic alloys. KGS-200 is the first machine of its kind to include on-board edge positioning sensors, enabling a fully automated process with immediate guidance for the operator. The sensors provide real-time feedback, helping to optimize the grinding, lapping, and polishing process and ensure the highest levels of precision and quality. KENT KGS-200 also provides a fully comprehensive range of custom solutions, offering flexibility and customization that is ideal for high-volume applications and production lines. From customized diamond grinding wheels to extreme-duty fixtures and optimized back-end process controllers, the tool is tailored for smooth performance and maximum efficiency. In addition, KGS-200 asset can be integrated with existing process systems and data acquisition systems, allowing for seamless integration with existing setups and improved production efficiency. Driven by innovation and carefully designed for performance, KENT KGS-200 is the perfect solution for any wafer grinding, lapping, and polishing need. With its robust design and flexibility, the model can scale up as needs change, allowing for a more sustainable and effective production process.

There are no reviews yet