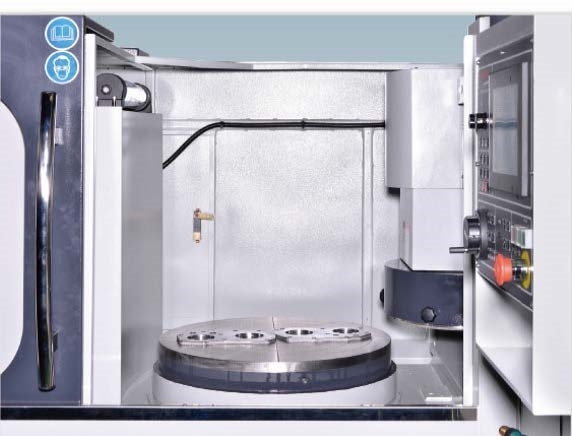

Used KENT RGV-600A #9281358 for sale

URL successfully copied!

Tap to zoom

ID: 9281358

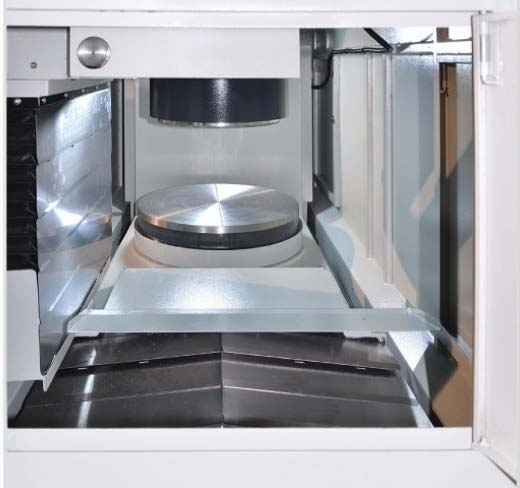

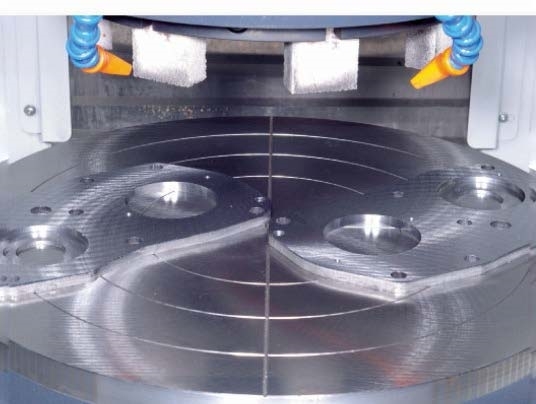

Rotary surface grinder

Maximum distance between spindle center and table: 17.72"

Maximum grinding radius: 12.8"

Magnetic rotary chuck (Dia): 23.62”

Magnetic rotary table rpm: Variable speed 10-150 rpm

Grinding wheel dimension: 14" x 1½" x 5" (OD x T x ID)

Main spindle motor: 1750 rpm (V-3 grade)

Siemens: 10 H.P

Auto down-feed motor: Servo 500 W

Horizontal spindle:

Precision and high efficient grinding process

Peripheral grinding allows for best finishes

Rapid up and down motor out cross motor for quicker setups

Flatness tolerance within 0.0002

LCD Touch screen conversational control system, 7.7"

Auto rotary speed adjustment simulating constant surface speed

MITSUBISHI Auto-down feed servo motor drive

Accessories:

Electro-magnetic rotary chuck

Grinding wheel dresser

Balancing base

Wheel flange

Balancing arbor

Toolbox with tools

Work lamp

Coolant tank with magnetic separator: 120 L

Manual parallel dresser

Electric parallel dresser.

Introducing KENT RGV-600A, an automated wafer grinding, lapping and polishing equipment designed to meet the demanding standards of today's advanced semiconductor chip production. The system features a highly efficient multi-stage process that enables high-precision machining of wafers using the latest grinding, lapping, and polishing techniques. At the core of the unit is a servo-driven spindle head, enabling high-accuracy polishing of wafers with remarkable cycle times. The elegant machine design with advanced features, such as auto-feed, remote capability, and automated program control, enables optimal surface finish and accuracy. RGV-600A combines a robust structure and motion control for maximum precision, as well as optimized polishing parameters for precise and reproducible processing results. The machine utilizes a two-step process—a first stage grinding process and a second lapping and polishing process—allowing operators to process double or uneven layers of wafers with utmost precision. The spindle head features a CNC tool with three tooling heads, enabling the asset to handle both circular and rectangular wafers. The model also features a built-in polishing pressure regulator to guarantee a consistent polishing pressure regardless of materials being processed. To enable precision control and quality, the equipment includes built-in polishing pressure control and auto-feed capacity to ensure wafers are always polished with the ideal level of pressure and the consistent accuracy of a single operator. To further optimize user experience and enable total control over the polishing process, the system employs a 100% servo-driven mechanism with state-of-the-art digital signal processing to ensure greater control over the dynamics of the grinding/polishing environment. KENT RGV-600A is specifically designed for factories that require very accurate machining of wafers in mass production. Its small footprint means it can fit in most work-spaces, while its sleek design adds to a clean, professional working environment. The unit is also fully compatible with all popular grinding, lapping, and polishing polishers, further increasing its appeal. All in all, RGV-600A is the perfect machine for advanced semiconductor fabrication, enabling unprecedented levels of precision and production capability.

There are no reviews yet