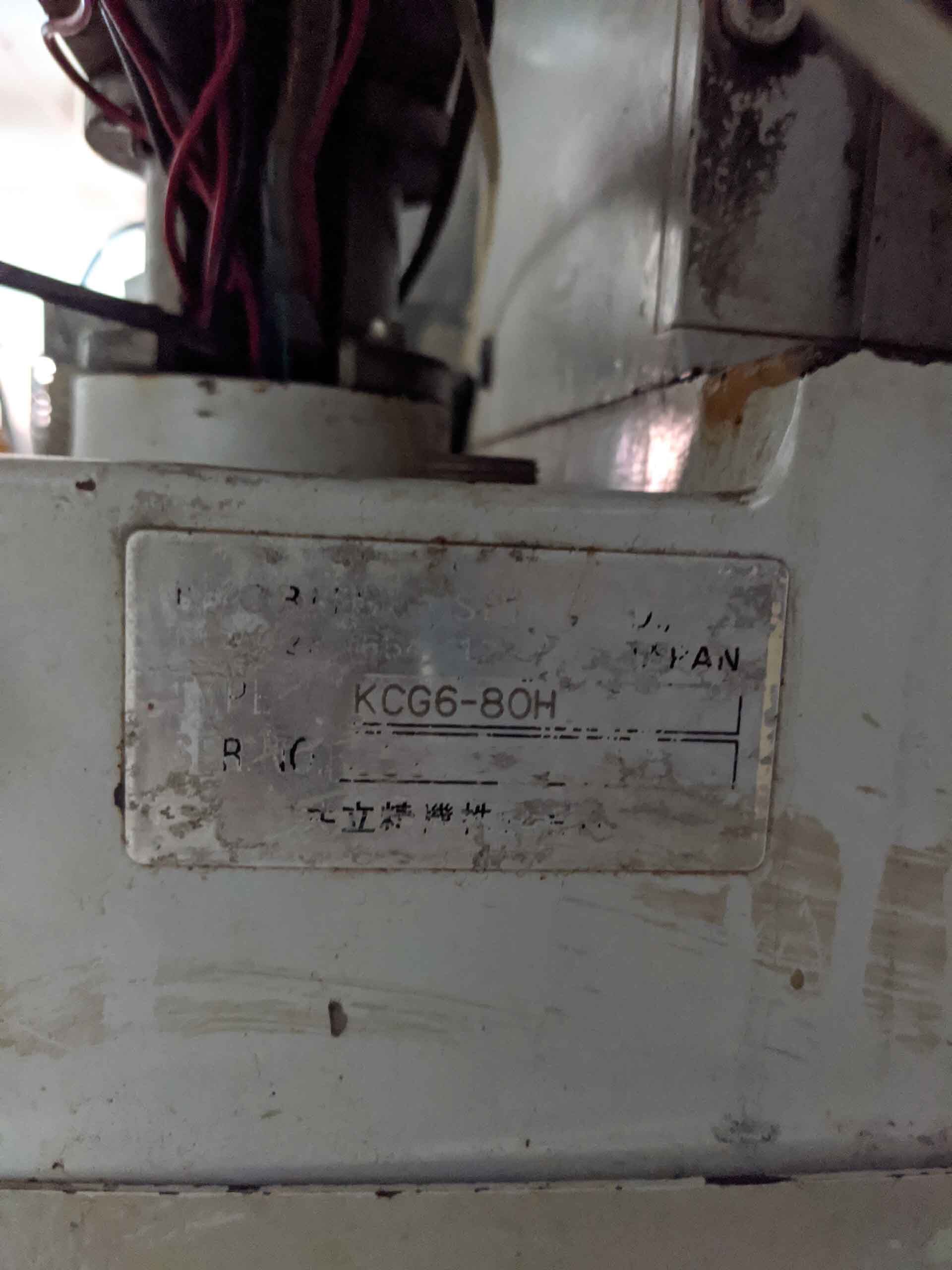

Used KYORITSU SEIKI KCG6-80H #293664144 for sale

URL successfully copied!

Tap to zoom

KYORITSU SEIKI KCG6-80H is a wafer grinding, lapping and polishing equipment, designed for achieving high levels of quality on wafer surface finishing operations. The system consists of a set of rotating discs and a set of stationary discs. The rotating discs are composed of an abrasive wheel, a viscous cup wheel, and a soft wheel. The abrasive wheel is used for efficient material removal (grinding), with its diamond particles ensuring a high level of precision. The viscous cup wheel is used for lapping, providing a smooth finish with a longer lifespan. The soft wheel is ideal for polishing and can be used with different polishing compounds to create a variety of finishes and desired surface replication. This unit features state-of-the-art technology that guarantees accurate grinding and polishing operations and produces a highly refined, scratch-free wafer surface. The high precision mechanical parts are well designed and efficient, offering low thermal drift performance for high reliability. Additionally, a unique internal flotation machine ensures precise surface finish regardless of substrate thickness variations. KCG6-80H is designed with a user-friendly interface to maximize productivity and minimize manual operations. The automatic loader and unloader units, programmable speed mode, and customizable process parameters further enhance its usability. An array of safety features such as a dust collector and emergency stop button ensure safe operation. Overall, KYORITSU SEIKI KCG6-80H is a fine wafer grinding, lapping and polishing tool that guarantees precise and reliable operations. With its automated process parameters, efficient technology, and user-friendly design, this asset will help reduce costs and improve production times, while generating superior surface finishes.

There are no reviews yet