Used LANDIS CINCINNATI RK Series 350-20 #9356511 for sale

URL successfully copied!

Tap to zoom

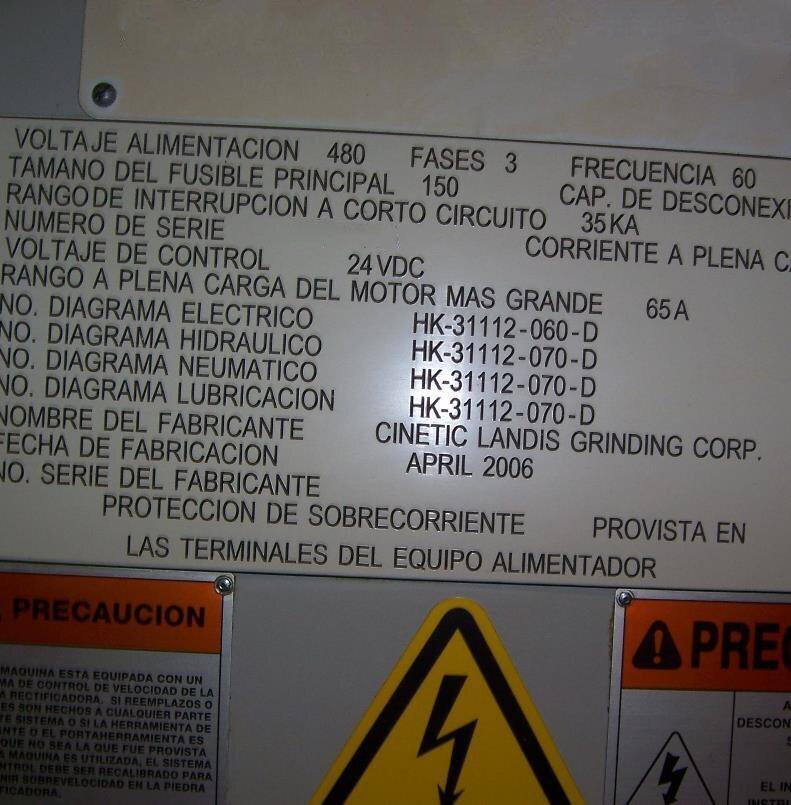

ID: 9356511

Vintage: 2006

Grinders

With loader and unloader

Machine base: Hooks included

Swivel plate: Anti-backlash single screw adjustment

Lower and upper slide: Anti-friction way system

Regulating wheel housing: Double-ended spindle support

Central coolant system

6400 CNC Control system

Operator controls

Machine enclosure

Single axis slide drive:

Precision backlash free

Pre-loaded heavy duty: 2 ½" Diameter ballscrew

AC Brushless servomotor

Two-way compensation: 0.000004" (0.1 micron)

Regulating wheel drive:

Variable speed (15-300 rpm)

AC Brushless servo motor

RPM Selectable

Grinding wheel spindle:

Filmatic double ended support (Twin grip)

Hydrostatic lift at spindle start-up

Grinding wheel dresser:

Selectable rate servomotor for the traverse axis

Servomotor diamond axis: 0.000004" (0.1 micron) resolution

Shank diamond holder: 7/16"

Regulating wheel dresser:

Shank diamond holder: 7/16"

2006 vintage.

LANDIS CINCINNATI RK Series 350-20 is a wafer grinding, lapping, and polishing equipment that features a rotating disk that allows for grinding, lapping, and polishing of multiple wafers simultaneously. The grinding disk can rotate at high speeds and is capable of executing several different operations. The disk can also be adjusted to optimize chip and die production. The grinding process is optimized by the use of a segmented diamond cutting head that provides optimal contact between the head and the wafer. The wafer grinding station also includes various lapping and polishing capabilities to improve surface finish and texture, as well as a metallographic polishing option to create a uniform surface finish on the sample. The system is equipped with a variety of features such as a CNC controller and integrated software that allow the user to have greater control over the grinding process, as well as advanced safety features such as light curtains and adjustable guards. The unit also comes with a variety of accessories such as an automated wafer loading machine and an automated cleaning tool to ensure a continual grinding and polishing process. RK Series 350-20 offers a flexible, efficient, and reliable grinding, lapping, and polishing process. With its fast speeds, adjustable parameters, and integrated software, the asset is capable of achieving an outstanding surface finish that will meet any detailed specifications. Furthermore, the model is highly reliable in operation and can be used to process a wide range of materials, including both silicon and sapphire. The equipment offers excellent stability, precision, and repeatability, so the user can be sure of the same results with each process cycle.

There are no reviews yet