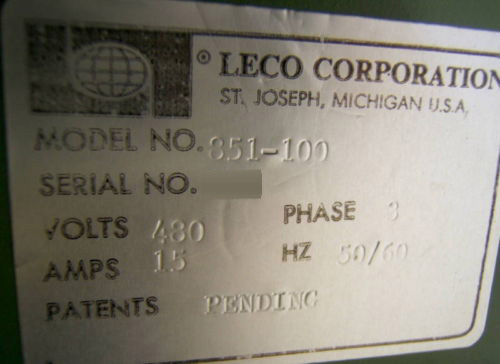

Used LECO 851-100 #9090597 for sale

URL successfully copied!

Tap to zoom

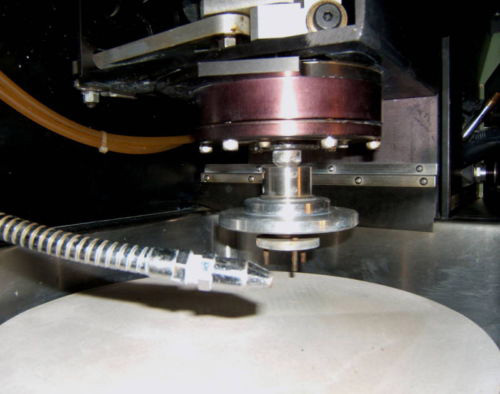

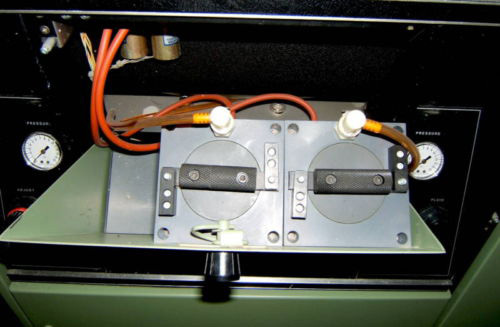

LECO 851-100 is a fully automated wafer grinding, lapping and polishing equipment that is designed to meet the high expectations of today's most demanding process engineers in the semiconductor industry. This system provides the highest level of accuracy and precision in the ultra-smooth polishing of semiconductor and other components. The unit features two main components, the wafer grinder and the polisher. The wafer grinder is capable of accurately grinding down most surfaces in a single step. It uses a precision-controlled laser to level the surface of the wafer so that the grinding is uniform across its entire diameter. The grinder is equipped with a computer-controlled 3-axis linear transport machine, ensuring a uniform grinding-width for each wafer. The precise grinding and surface leveled by the grinder eliminate the need for post-processing grinding. The polisher is then used to secure the desired surface quality on the wafer. It utilizes a heavy-duty precision indexer to locate the polishing surface and to obtain the ideal polishing contact pressure. The polisher also features a 3-axis robot head capable of precisely controlling the polishing movement. The polisher is also capable of continuously monitoring the contact pressure, enabling the application of consistent polishing force across the entire surface of the wafer. This ensures that the surface of the wafer is evenly and consistently polished. 851-100 also features an easy-to-use human machine interface (HMI) that provides an intuitive control of all tool functions. The asset allows for easy operation and model optimization, while providing all the necessary data logging and analysis capabilities for reliable process monitoring and control. The integrated real-time process monitoring display allows for fast tuning of lapping parameters to ensure process stability. Overall, LECO 851-100 is an essential tool for the semiconductor industry, providing precisely and uniformly polished semiconductor components quickly and cost effectively. This high-performance equipment is designed with safety and accuracy in mind, eliminating the need for intensive manual grinding and polishing, while reducing operation costs and time.

There are no reviews yet