Used LOGITECH 1CM51-CDP #9379071 for sale

URL successfully copied!

Tap to zoom

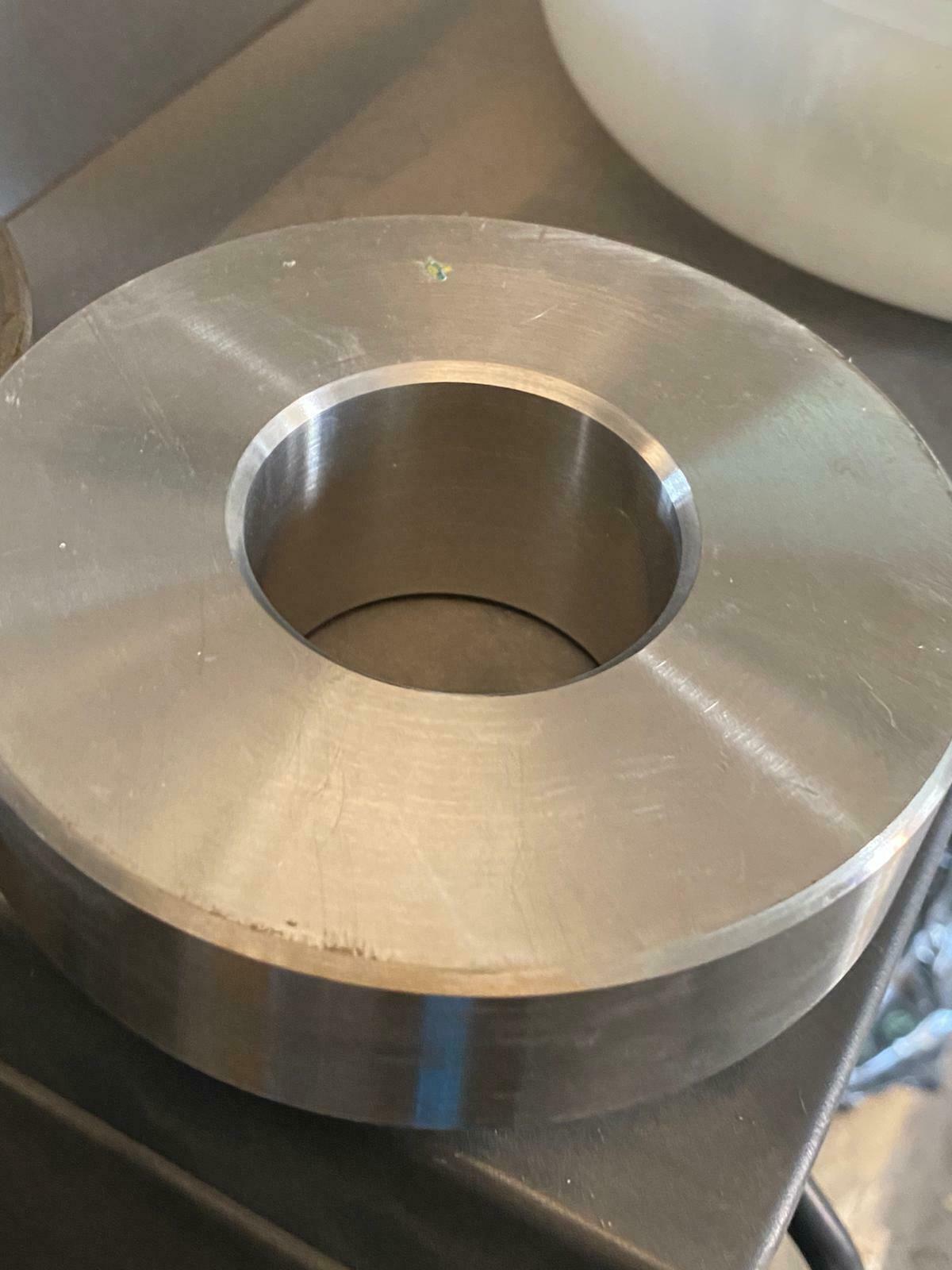

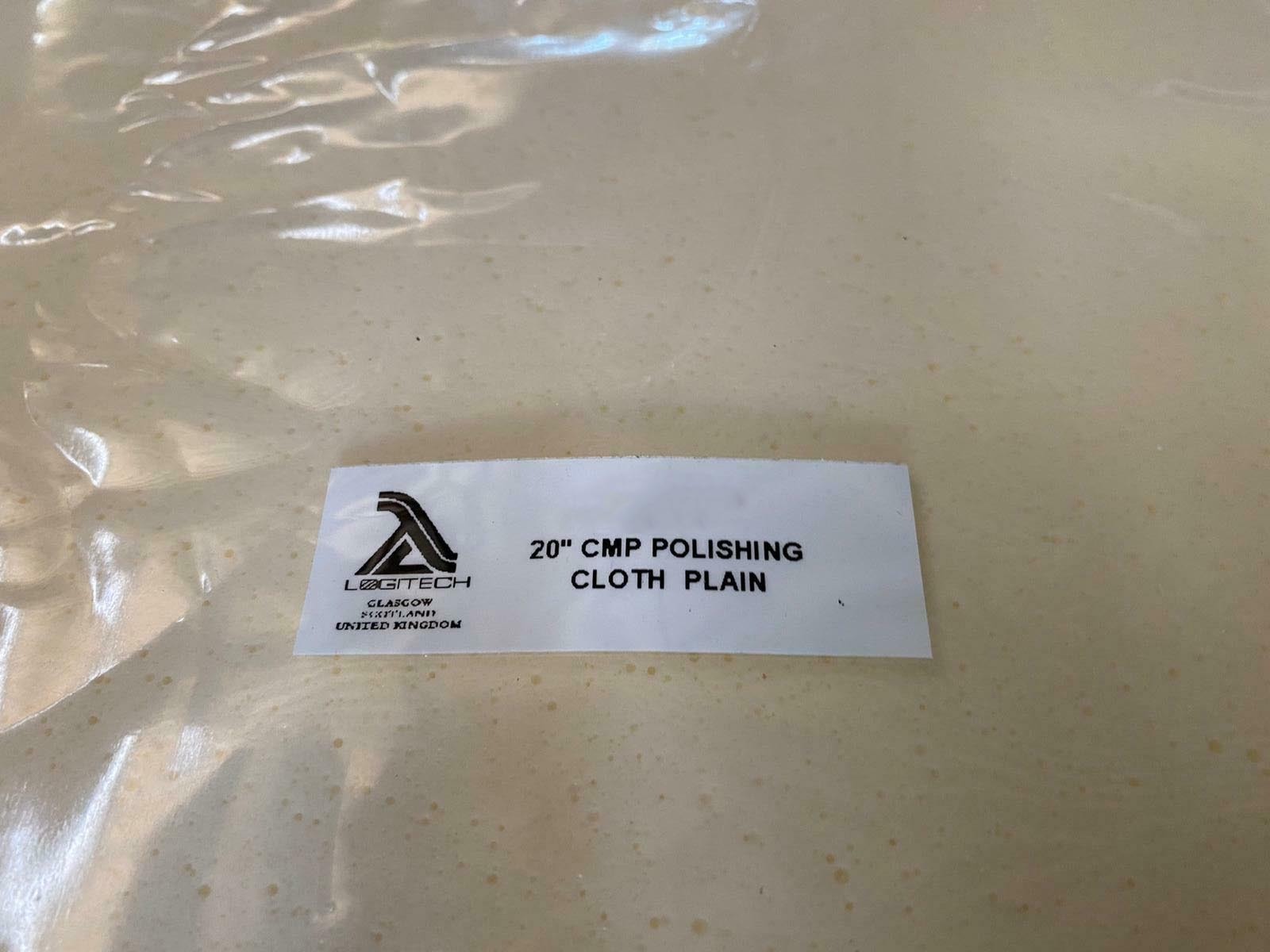

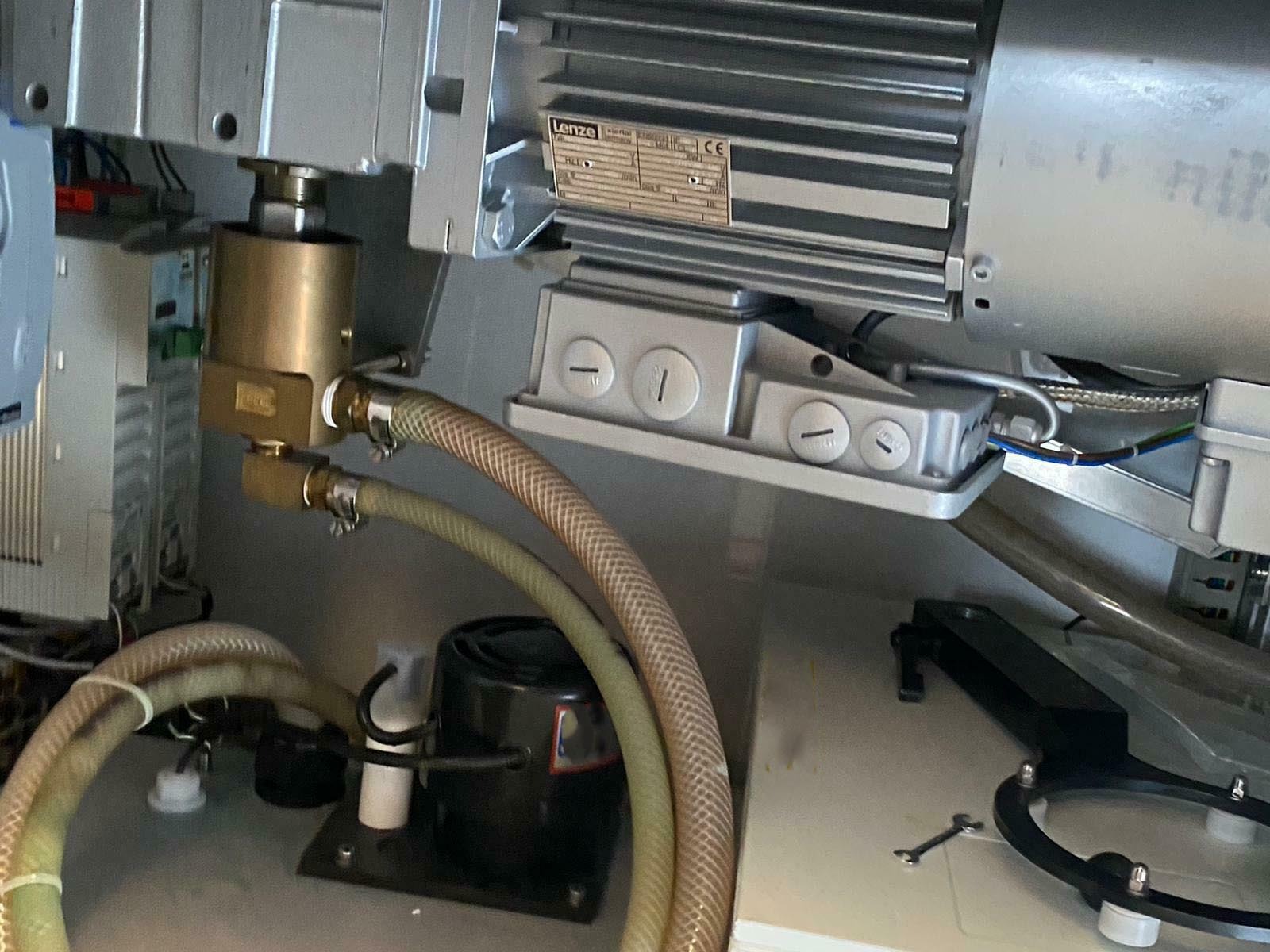

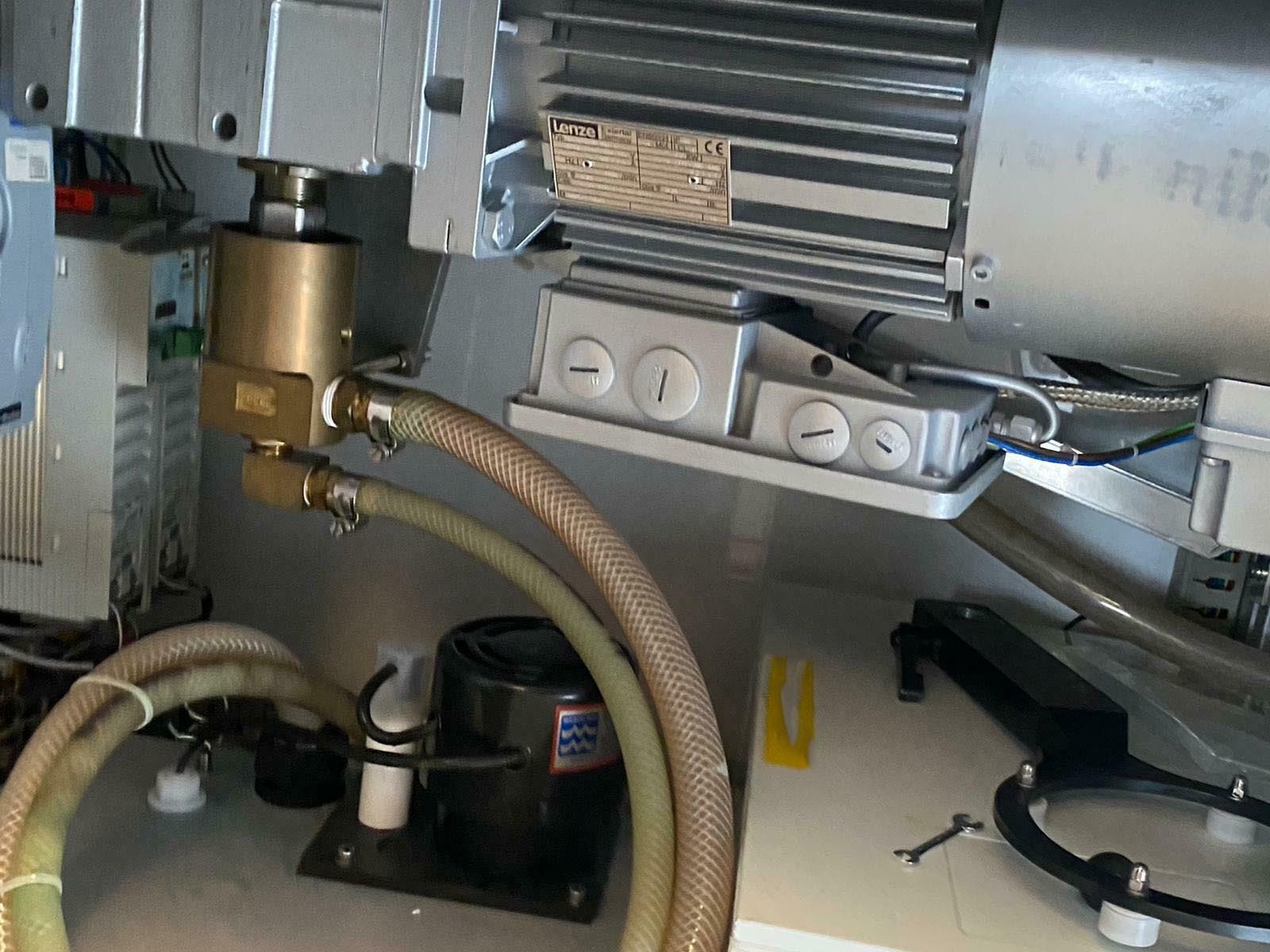

LOGITECH 1CM51-CDP wafer grinding, lapping & polishing equipment is an automated, computer controlled polishing system designed to provide high precision and low defect wafer surface accuracy. The unit is designed with the latest automation technology, allowing for the highest throughput and most reliable performance. The machine utilizes a three-axis gantry robot, driven by a high performance servo motor, to provide precise, repeatable, and accurate motion in the X, Y, and Z axes. The gantry robot is able to move and manipulate wafers up to 800 millimeters in diameter, utilizing a dual stage wafer support tool to provide high precision and repeatability. The asset also utilizes a state-of-the-art, vision-based alignment model for precise wafer positioning and robotic tool path accuracy. 1CM51-CDP is a fully enclosed equipment, featuring integrated process and diagnostic monitoring and controls. The system is capable of both single-sided or dual-sided grinding, lapping, and polishing operations. Grinding is accomplished through the use of single sided dowel-mounted diamond wheels, while lapping is performed on a specially designed two-sided lapping plate. The unit is capable of surface roughness (Ra) finish of less than 1.0 nanometer, and can generate wafer surface defect free results. In addition, the machine produces low residual stresses within the wafer, making it ideal for a wide range of applications and substrates. The tool supports a variety of wafer materials including, but not limited to Silicon, Sapphire, Quartz, and Gallium Arsenide. The asset is designed for safe, efficient, and low maintenance operation. The model also has a comprehensive safety interlock equipment featuring an array of motion and safety systems, and a servo-driven enclosure to ensure the safety of both the system and the operator. LOGITECH 1CM51-CDP wafer grinding, lapping & polishing unit is a highly versatile and reliable solution for achieving accurate, precise, and defect-free wafer surfaces. The machine's advanced controls and processing capabilities, coupled with its powerful and reliable servo-driven motion systems, make it the ideal choice for those looking for a high performance, economical tool for processing a wide range of wafer materials and substrates.

There are no reviews yet