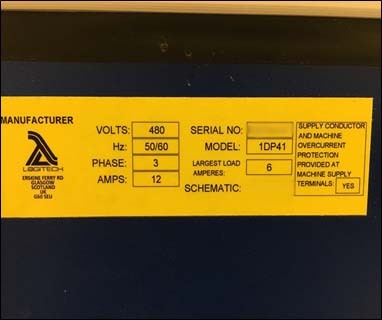

Used LOGITECH 1DP41 #9176285 for sale

URL successfully copied!

Tap to zoom

LOGITECH 1DP41 wafer grinding, lapping and polishing equipment is designed for the creation of high end semiconductor devices. The system is divided into two distinct operations; grinding and polishing. Grinding is used to achieve the desired shape, size and roughness of the substrate wafer. This is achieved with the introduction of a special grinding belt that is capable of removing a controlled amount of material from the surface of the substrate. The specific structure of the belt is tailored to the specific requirements of the customer's substrate. This advanced belt is capable of achieving an optimal shape and size for the target product. After the grinding process is complete, the polishing operation begins to finish the surface of the substrate. The polishing is achieved through the use of a range of special abrasives. Using the right combination of abrasive materials in the right order can achieve the desired surface finish. The unit controls the introduction and progression of the abrasive materials as they work to finish the surface of the substrate. In addition to the grinding and polishing operations, 1DP41 also includes advanced software that is designed to monitor and control the entire process. This software allows the user to monitor the progress of the operation in real-time. The software also assists in optimizing the operation to ensure that the best possible finishing of the substrate is achieved. Overall, LOGITECH 1DP41 is a powerful and advanced machine that is designed to provide reliable and efficient wafer grinding, lapping and polishing. The tool is capable of precisely controlling the whole process from start to finish, optimizing the operation and ensuring that all of the critical specifications of the substrate are met. With its advanced software, 1DP41 is an excellent asset for the production of high quality semiconductor devices.

There are no reviews yet