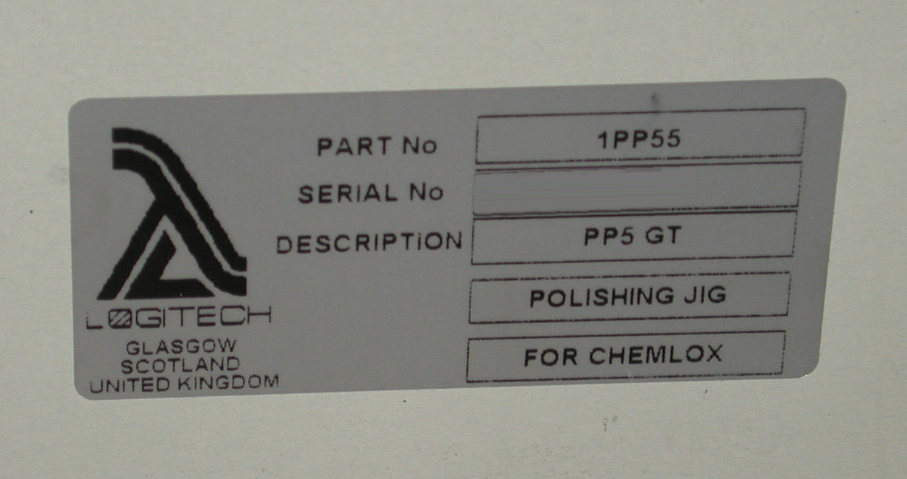

Used LOGITECH PP5 GT #9111500 for sale

URL successfully copied!

Tap to zoom

LOGITECH PP5 GT is a high-precision wafer grinding, lapping, and polishing equipment designed for a multitude of metrology, semiconductor, and solar wafer applications. The system is based on the company's precision-engineered single-axis grinder, lapper, and polisher (SPG/L/P) platform for grinding, lapping, and polishing a variety of materials and substrates. PP5 GT is designed to grind, lap, and polish in one pass with excellent precision and repeatability while helping to achieve the most accurate and consistent surface finishes required by semiconductor device production. LOGITECH PP5 GT features a double-torch unit with two large single-axis grinder/lapper/polishers on either side. The two-torch machine allows for faster processing of the wafers, ensuring that the grinding, lapping, and polishing are done in the quickest time possible. The torches consist of three motorized feed axes and are designed to allow for manual as well as automated operations. The motors are mounted in an ergonomic enclosure for easy maintenance and operational access and feature built-in safety devices for added protection. PP5 GT has a maximum wafer size of three inches and is capable of processing a range of materials and substrates, including polyimide, aluminum oxide, silicon nitride, and others. The tool is equipped with autoupgrading wheels and can be tailored to suit the user's material and application needs. The wheels are available in different grades to support precision grinding, lapping, or polishing. LOGITECH PP5 GT utilizes advanced optical features such as fixed optics, dynamic focus, single- or dual-beam laser systems, and laser micron accuracy. These features ensure that the wafers can be processed quickly and accurately, resulting in better surfaces finishes. The asset also includes the company's state-of-the-art data acquisition, analysis, and reporting software package. This software is designed to make data collection and reporting of wafer processing parameters simple and efficient. It also enables engineers and operators to monitor and review the wafers as they are being processed, ensuring that all parameters remain within tolerance. Overall, PP5 GT is an excellent choice for any semiconductor, solar, or metrology wafer processing application. It is highly reliable and efficient and is capable of providing excellent repeatability, accuracy, and surface finish quality. It is an ideal choice for production and research applications alike.

There are no reviews yet