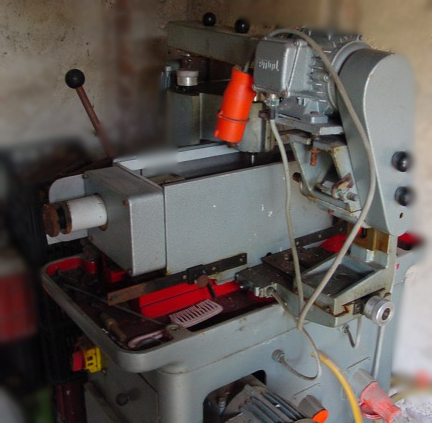

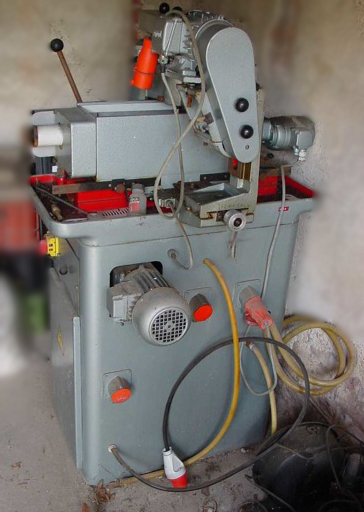

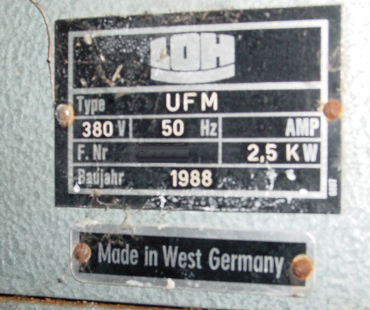

Used LOH UFM #55544 for sale

URL successfully copied!

Tap to zoom

LOH UFM is a wafer grinding, lapping, and polishing equipment designed to meet the needs of the semiconductor industry. It is capable of producing flat, high-quality, precision semiconductor wafers with surface roughness values ranging from 5 to 12Aa, while utilizing low costs and short process times. It features a three-axis computer numerical control (CNC) with integrated sensors, allowing for the accurate grinding, lapping, and polishing of a variety of semiconductor materials. At the heart of UFM is a powerful grinding spindle with a rotational speed of up to 10,000 rpm and a precision of 0.05 μm. This spindle is capable of grinding to as low as .2 μm surface roughness, offering excellent results in even the most intricate applications. In addition, this grinding spindle also includes a built-in work-holding device for greater accuracy and convenience. The system also includes a pair of upper and lower lapping tables for lapping of the glass and silicon wafers. The lapping tables feature built-in air showers, which provide the best results possible. The air showers allow the wafers to stay in place while they are lapped, leading to greater accuracy and precision with each wafer. The polishing process occurs on a dedicated polishing machine that features a two-axis CNC polishing table with a rotational speed of up to 8,000 rpm. This polishing table is designed to uniformly lap, polish, and finish the wafers, producing a perfect surface with a precision of 0.10 µm. Finally, the unit includes a fully automated thin-film deposition station that deposits a thin film of polymer onto the wafer surface. This thin film provides an even, smooth surface, producing a wafer that is perfectly flat and smooth with a very low roughness. In conclusion, LOH UFM is a powerful and accurate wafer grinding, lapping and polishing machine that is perfect for the semiconductor industry. With its powerful grinding spindle, precision air showers, and full-featured CNC polishing table, this tool is capable of producing flat, high-quality wafers with minimum time and cost.

There are no reviews yet