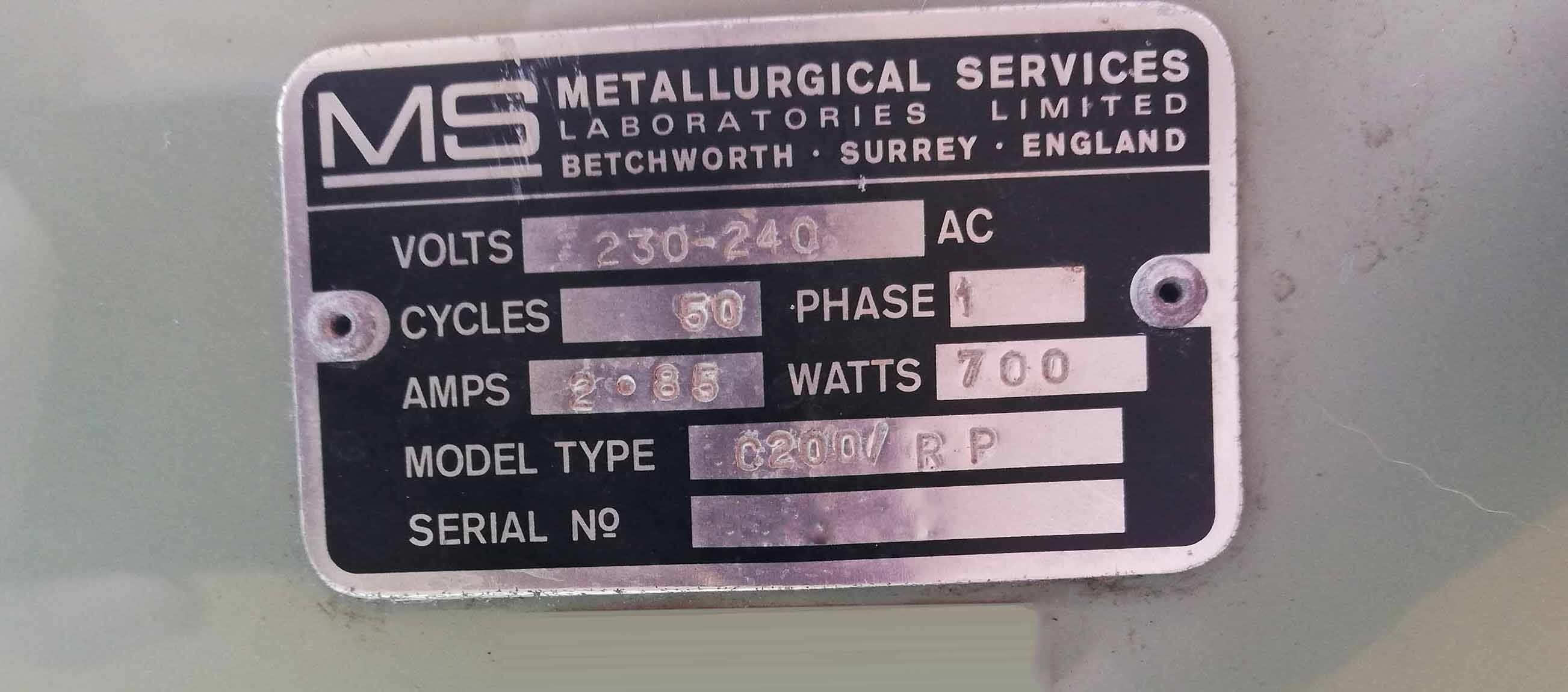

Used METASERV 2000 #9212906 for sale

URL successfully copied!

Tap to zoom

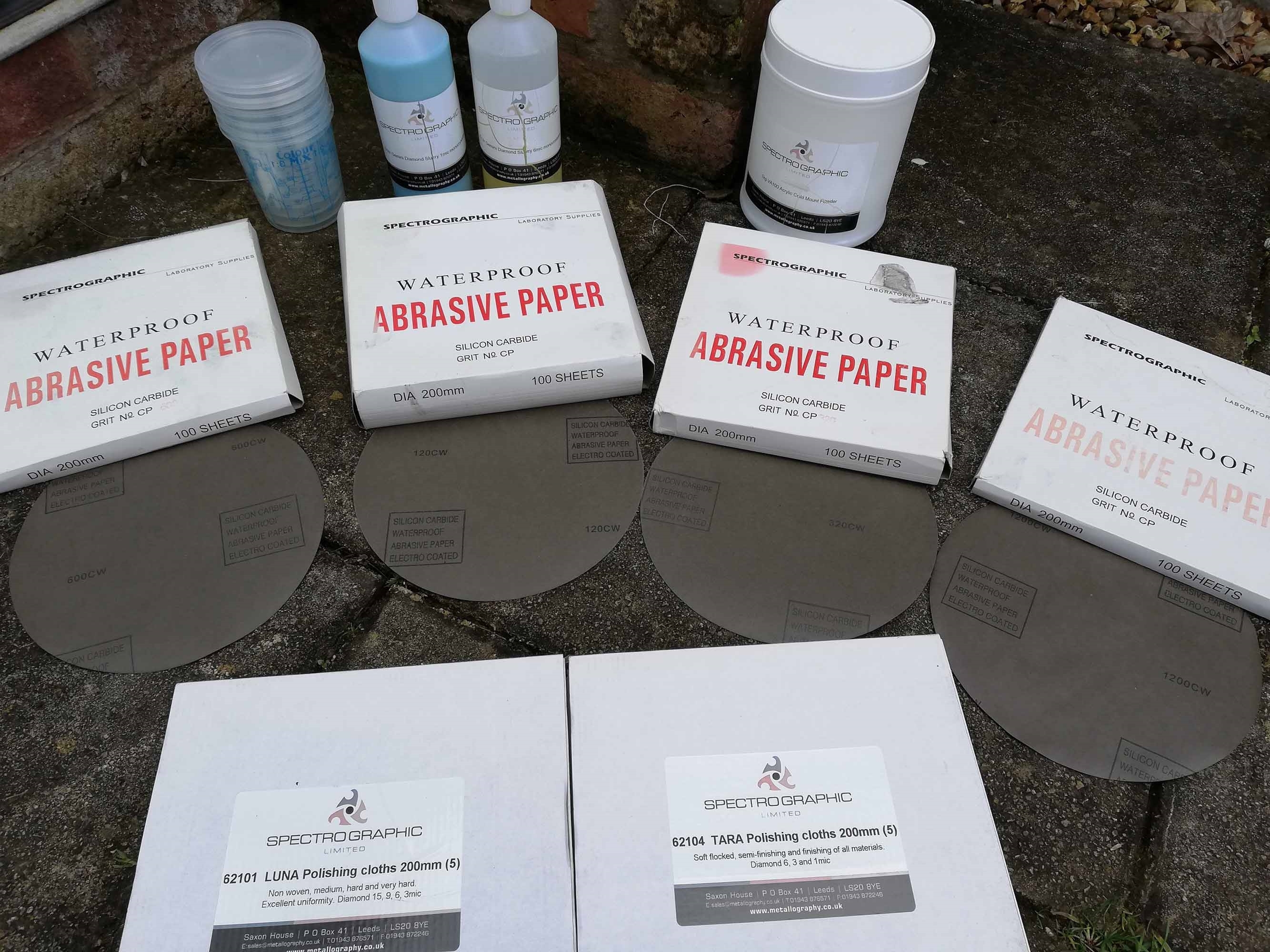

METASERV 2000 is a wafer grinding, lapping, and polishing system manufactured by METASERV Technology, Inc. It is a highly automated and cost-effective solution that is designed to meet the rigorous demands of the semiconductor industry. The machine is capable of achieving a variety of processing parameters with a constant feed rate and finish quality. The core technology of 2000 is its precision servo-controlled grinding spindle that can produce ultra-precise results and offers excellent repeatability. The spindle head is constructed from advanced no-resonance synthetics and contains an integrated motor and electronic controller to provide precise adjustments and automatic motor control. The motor is tuned for maximum stability and all electric signals are monitored for stability and consistency, which allows for accurate control of torque and grinding power. METASERV 2000 includes several different grinding, lapping, and polishing heads for a wide range of applications. Each head is constructed from a specific grade of diamond impregnated polymer and is pre-set for a specific range of feed rates, grinding forces, and speeds. This allows operators to quickly and reliably produce different finish characteristics on different types of materials. The lapping and polishing operations are fully automated and have a range of features including automatic feed-rate and pressure control, angle compensation, and zone control. 2000 is also designed to have minimal environmental impact. Its low-noise operation contributes to a more pleasant working environment, while its dust and particle containment features help to create a safe and clean working area. Finally, METASERV has been designed to maintain optimal efficiency over an extended useful life, helping to reduce waste and associated costs. In conclusion, METASERV 2000 offers reliable, high-quality results and is a cost-efficient solution for a wide range of wafer grinding, lapping and polishing applications. Its precision servo-controlled spindle and advanced materials enable highly consistent and repeatable results for a wide range of processes and materials. Its many features and low environmental impact make it an ideal choice for semiconductor manufacturers.

There are no reviews yet