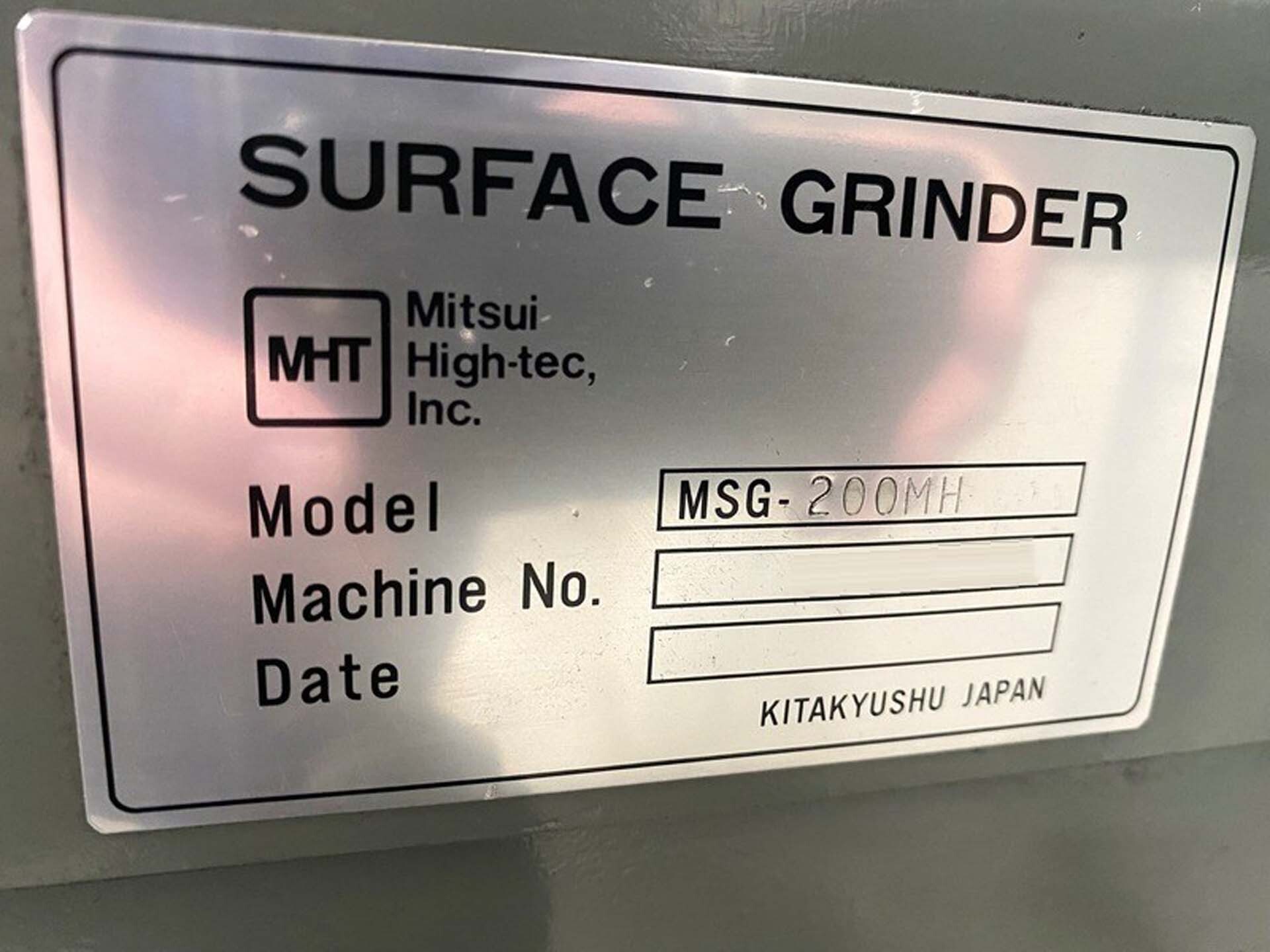

Used MITSUI SEIKI MSG-200MH #9390528 for sale

URL successfully copied!

Tap to zoom

ID: 9390528

Vintage: 1997

Surface grinder

WALKER CEREMAX Perm-mag chuck

Chuck size: 6" x 12"

Maximum longitudinal table travel: 15"

Maximum cross table travel: 8"

Maximum height from centerline spindle to table top: 18"

Maximum grinding length and width: 19-3/4 x 7"

Table movement per head wheel revolution: 4" / Rev

Vertical feed per revolution of handwheel: 0.0500" / Rev

Cross feed per revolution of handwheel: 0.100" / Rev

Spindle type: Horizontal

Precision cartridge spindle: 1-1/3 HP

Grinding wheel size: 8" x 3/4" x 1-1/4"

LUBE CORP Electric lubrication system

VAC-U-GUARD Wheel guard

Power supply: 220 V, 3/60 Cycles

1997 vintage.

MITSUI SEIKI MSG-200MH 'wafer grinding, lapping & polishing' equipment is designed to provide an efficient, accurate and precise method for finishing wafers and other substrates. The use of MSG-200MH system substantially reduces the cost of polishing, grinding and lapping of wafers. MITSUI SEIKI MSG-200MH consists of a mainframe that houses the motor and mounting hardware for the grinding and polishing heads, as well as the air pumps and cooling unit. The grinding and polishing heads are programmable and customisable according to needs. This allows the user to control the speed, pressure, distance and timing of the process. The grinding and polishing heads are built to quickly remove material from wafer's surface, providing a smoother and more uniform finish. The machine is capable of precisely controlling the amount of material removed via its laser height measurement, which ensures consistent processing results. The dynamic pressure control feature ensures that the grinding and polishing surface remains consistent and the pressure controlled precisely acts on the wafer to improve the quality and efficiency of the processing. MSG-200MH is equipped with a high-speed, high-precision machining capability. In order to achieve high accuracy, the tool uses a high-precision guide asset and a rotary table, which allow for precise machining of difficult substrates. MITSUI SEIKI MSG-200MH is capable of finishing various materials and products quickly and precisely. It also comes with a range of built-in safety features, including an emergency stop switch and a power-off model that promptly shuts down power to the equipment and all its components in order to prevent any potential physical harm to the user. MSG-200MH is a cutting-edge wafer grinding, lapping and polishing system that offers superior performance and reliability. It can be used to process a variety of materials and provides a reliable and efficient method to achieve the highest quality of wafer finishing.

There are no reviews yet