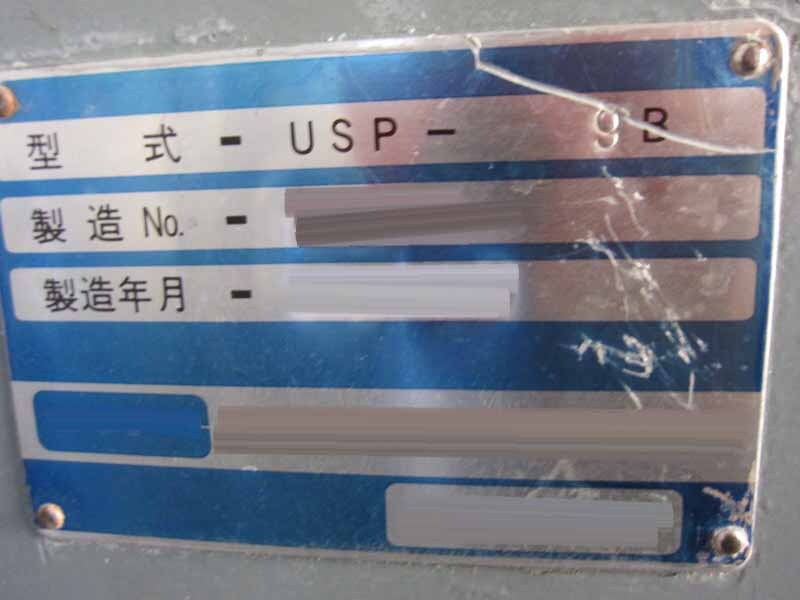

Used NAICHI FUJIKOSHI USP-9B #9166539 for sale

URL successfully copied!

Tap to zoom

The NAICHI FUJIKOSH I NAICHI FUJIKOSHI USP-9B is a wafer grinding, lapping, and polishing equipment designed for ultra high precision wafer fabrication. It is ideal for emerging semiconductor device production due to its highly precise and repeatable process. The system utilizes a range of motion systems, including vibration, rotation, and linear drive, to precisely grind, lap, and polish each wafer. To begin the wafer grinding process, the wafer is placed in a chamber and secured to the wafer holder. The edge of the wafer is then confronted with a grinding wheel using vibration or linear drive motion. It provides a high power and precise grinding wheel, which enables the grinding of wafers with good roundness and surface roughness. The grinding process is then regulated by the unit's control machine, ensuring precise adjustment of the grinding wheel motion parameters. The wafer lapping process is then conducted in the same chamber, using a lapping media composed of diamond abrasives to achieve superior flatness and surface finish. This process is performed by utilizing either a rotation or linear drive motion, dependent on the desired finish. The wafer is then precisely lapped in a controlled environment to achieve the desired finish. The final step in the process is the polishing of the wafer. A diamond slurry is used to polish the surface of the wafer, and is again undertaken in the same chamber. The polishing process is regulated by precise and repeatable motion parameters, which provide superior surface characteristics in the finished wafer. The completed wafer is then removed from the tool and inspected. USP-9B ensures the production of wafers with superior levels of surface precision, wafer finish, and geometry. This asset is ideal for high precision industries, such as semiconductor device applications, where tight tolerances and consistent results are paramount.

There are no reviews yet