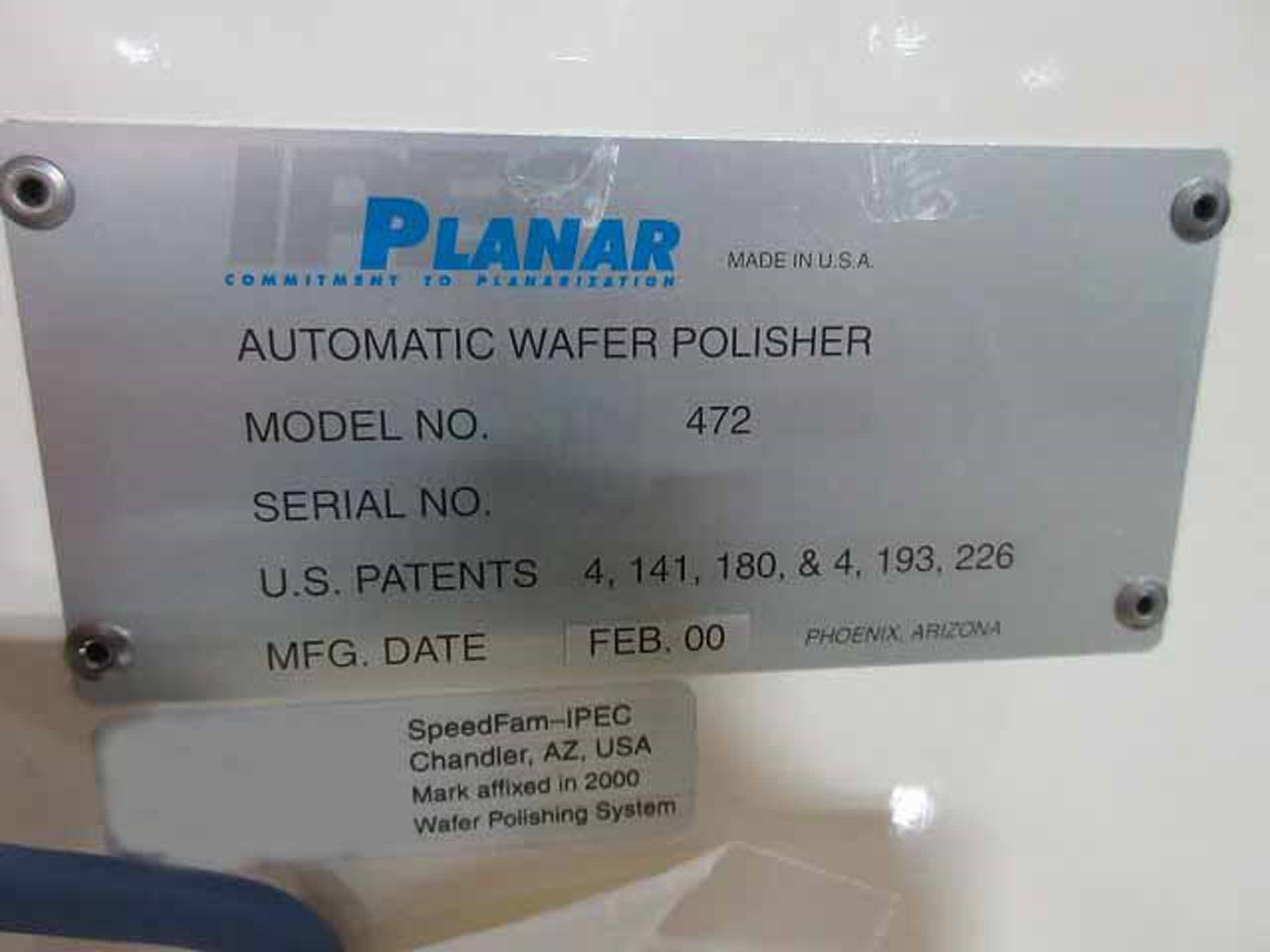

Used NOVELLUS Avanti 472 #9225550 for sale

URL successfully copied!

Tap to zoom

NOVELLUS Avanti 472 is an advanced wafer grinding, lapping and polishing equipment that helps fabrication facilities keep up with the increasingly strict requirements for wafer accuracy and integrity. With a multi-dimensional design that couples high-precision motion systems with industry-leading software and cutting-edge robotics, NOVELLUS AVANT I472 is an integral tool for modern wafer fabrication. The 472 includes a multi-axis work envelope that allows users to finish wafers with up to two degrees of freedom along each axial plane. The movement of the abrasive tools is precisely controlled by digital command signals and servo motors. This, coupled with the variable speed controller for spindle driven tools, creates the capability to deliver smooth, precise, repeatable processes.The 472 includes a number of safety features, including E-Stop and safety PLCs, as well as options for wafer marking and full process automation. NOVELLUS 472 also has a user-friendly control panel. The easy-to-use graphical interface allows users to quickly set up the system, as well as quickly and accurately monitor the progress of each wafer. The 472 also has a library of preprogrammed processes for wafers of different sizes and thicknesses. This helps keep operators focused on the task at hand and eliminates the need to enter the same parameters each time. Avanti 472 also offers several facilities to improve the quality of the wafers. For instance, the 472 uses a programmable grit element that ensures a consistent lapping motion. The 472 also includes an advanced 3D inspection unit, which allows highly accurate measurement of plan views and topographical features. This helps ensure the integrity of the finished wafer. Overall, AVANT I472 is an essential tool for wafer fabrication facilities. It offers unmatched accuracy and repeatability with its multi-axis work envelope, digital command signals, and variable speed control. The user-friendly control panel and preprogrammed processes help operators remain focused on the task at hand. Additionally, the inclusion of the 3D inspection machine helps ensure the integrity of the finished wafers.

There are no reviews yet