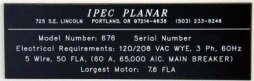

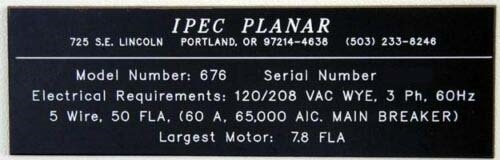

Used NOVELLUS / IPEC / WESTECH / SPEEDFAM Avantgaard 676 #9276834 for sale

URL successfully copied!

Tap to zoom

ID: 9276834

CMP System, parts machine

With MP400 Polisher

Interconnecting cables

Throughput: >40 Wafers/hr

Fully automated cassette to cassette (C2C)

(4) Wafer planarizers

Endpoint detection

Dual pad conditioning

Electrical cabinet

Spray box assembly

Automated wafer handling robot

Wet cassette assembly

Dual cassette basin

System Control (SysCon)

Control station

Head assembly

Internal bearings

Polish dynamics

Polish pad

Endpoint detection system

Manual

Includes:

Main polishing unit

Chase control panel

GENMARK Gencobot 3L / 4 Robot with end-effector

(25) M-825 Wafer address sensors

Chemicals:

Hydrogen peroxide concentration: 7.4% to 50%

W2000 Semi-sperse: DI Water and proprietary metal oxide

Power supply: 120/208 VAC WYE, 3 Phase, 60 Hz, 60 A.

NOVELLUS / IPEC / WESTECH / SPEEDFAM Avantgaard 676 is an advanced wafer grinding, lapping, and polishing equipment. This system is designed to give precise control over a variety of processes, ensuring the highest quality results. The Avantgard 676 is equipped with a high-powered diamond grinding head, which is used to grind down the surface of semi-conductor wafers. This head can achieve a grain size of less than 0.4 micron. The Avantgard 676 is also equipped with a lapping unit with a variable speed of up to 120 rpm, which is used to polish the wafer to a smooth, even surface. This lapping machine has a head capable of achieving a surface roughness of less than 0.6 nanometers. The Avantgard 676 is equipped with a powerful four-point, servo-controlled polishing tool. This asset utilizes a patented "servo-polishing" technology, which gives the operator great control over the polishing process. The Avantgard 676 also features an advanced IPEC cleaning model, which utilizes pressurized nitrogen jets to remove microscopic particles that remain on the surface of the wafer after the grinding and lapping process. This technology helps ensure that the wafer surfaces are as clean as possible and free from contamination. Additionally, the Avantgard 676 is designed to be user-friendly and highly-efficient. Its operator interface features a touch-sensitive display that provides easy access to the controls of the equipment and has preset programs for specific applications. It also features a built-in diagnostics system that can recognize and alert personnel to problems as they occur. The machine is also equipped with a comprehensive monitoring and alert unit, which helps reduce downtime and ensures that the grinding, lapping, and polishing process are running smoothly. Overall, IPEC Avantgaard 676 is an advanced machine that allows operators to quickly and accurately grind, lap, and polish semiconductor wafers. This tool features a powerful diamond grinding head, lapping asset, and polishing model that gives precise control over the process. Additionally, it features user-friendly, easy-to-use interfaces and monitoring systems that help to reduce downtime and ensure the highest quality results.

There are no reviews yet