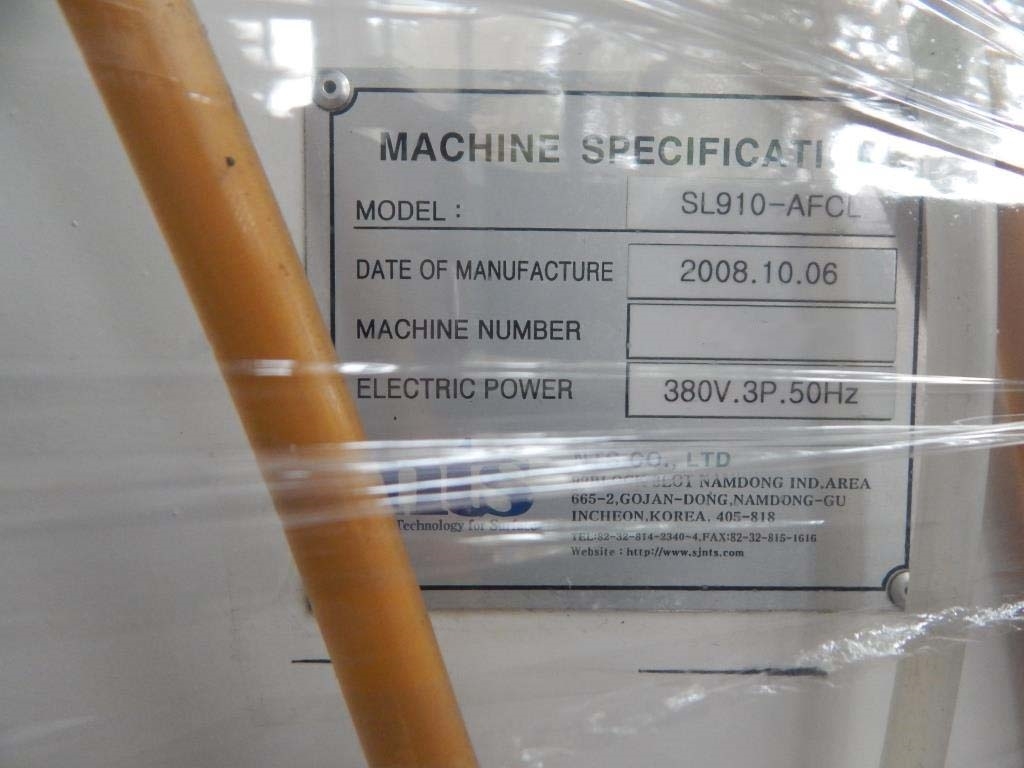

Used NTS Nano Surface SL910-AFCL #9132557 for sale

URL successfully copied!

Tap to zoom

ID: 9132557

Vintage: 2008

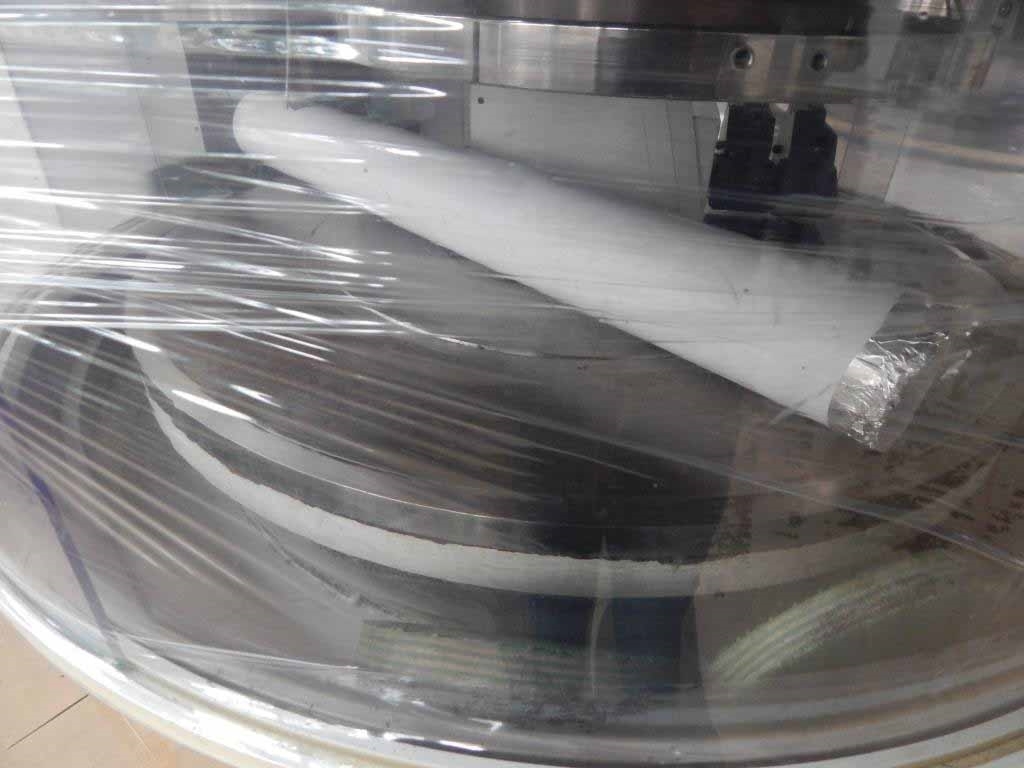

Single diamond polishing systems

Polishing heads

Plate non step variable speed system: Smooth start / Stop feature

(4) Holder type pneumatic pressure systems / Level type

Real-time control temperature

Automatic diamond slurry spray system: 2 Points

4-Axis pressure plate water cooling system

(2) Pneumatic step pressure systems: Cylinder ф80 x 200 st

Machine emergency auto-stop function

Hume protective / Exhaust system

Spindle housing system

Lapping plate water cooling system

IR Temperature reading system

Pressure plate: ф360 (Sus 304)

Drop slurry supply system

Timer (Process time)

Solid frame structure

Hand shower: 2 Spots

(2) Auto stirrers

(2) Spray nozzles

Plate: 15~80 RPM

Semi-automatic:

Precision lapping plate facing and grooving system

One time grooving: 150 um Deeps

Input voltage: 220 V, 50/60 Hz, 3 Phase

Main motor: 220 V, 50/60 Hz, 3 Phase, 7.5 kW

2008 vintage.

NTS Nano Surface SL910-AFCL is a wafer grinding, lapping, and polishing equipment, designed for the demanding requirements of silicon wafer production. This system is capable of producing high quality silicon wafers with nanometer-level surface finishes, offering manufacturer a reliable and efficient tool for the production of their most sensitive devices. The unit utilizes a lapping plate with a motorized head, and a variety of compound grinding and lapping discs to produce a flawless finish on both sides of the wafers. A special feature of the machine is its Automatic Flush Control Liquid (AFCL) technology, which allows the tool to automatically dispense chemical reagents onto the lapping plate surface while machining, improving the surface finish and overall quality of the finished product. The ceramic grinding discs are adjustable to set the proper level of grinding and lapping needed for each wafer process. The abrasive discs have a wide range of granulometry for fine-tuning the surface finish and stock removal, allowing for a variety of finishes to be achieved. This automated asset can be operated from a single point of control and features an intuitive interface that guides operators through the entire process. The variable speed drive on Nano Surface SL910-AFCL allows for precision control over the lapping process, making it easy to achieve the exact surface finish and thickness required for the job. The model automatically maintains consistent pressure on the wafer to ensure extraction of the specified surface finish and thickness. The temperature is controlled to prevent heat gain on the wafer and to minimize any thermal damage. The SL910-AFCL equipment has a variety of safety features, providing protection for the operator as well as the material being machined. A double-door access with a vacuum system prevents particles from escaping into the work area while the machine is running. The unit is also designed in accordance with ESD requirements, to prevent electrostatic damage to the wafer. Overall, NTS Nano Surface SL910-AFCL is a reliable and efficient wafer grinding, lapping, and polishing machine, capable of producing high quality silicon wafers with nanometer-level surface finishes. Its Automatic Flush Control Liquid technology and other features enable the tool to maintain a consistent and precise finish on the wafer. With its intuitive and user-friendly interface, the SL910-AFCL is an ideal asset for a variety of applications.

There are no reviews yet