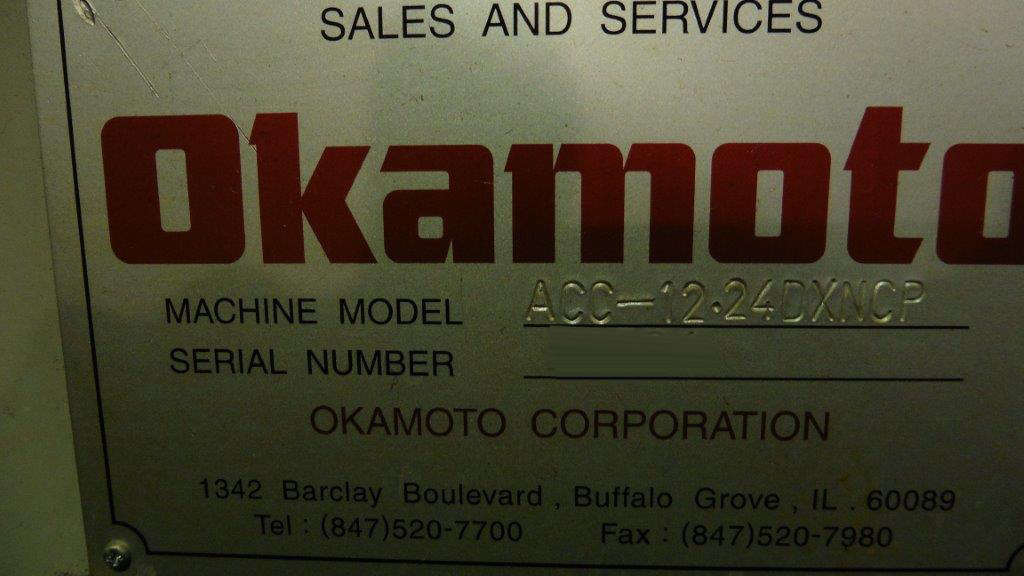

Used OKAMOTO ACC-12-24DXNCP #9101611 for sale

URL successfully copied!

Tap to zoom

ID: 9101611

Vintage: 2007

CNC Profile surface grinder, 12" x 24"

FANUC 21i-MB CNC Control

Table capacity:

Nominal grinding capacity: 12" x 24"

Maximum height under 12" wheel: 13.6"

Longitudinal feed (X-Axis):

Table speed, infinitely variable: 3' - 82' Fpm

Maximum longitudinal table movement: 26.0" (Manual)

Feed per hand wheel revolution: 1.85"

Crossfeed (Z-Axis):

Maximum saddle travel: 9.0"

Intermittent traverse feed: 0.002" - 0.40" Ipm

Grinding feed: 0.001" - 40" Ipm

Rapid feed: 40" Ipm

Jog feed: 0 - 40" Ipm

Manual pulse generator: 0.00001", 0.0001", 0.001"

Grinding wheel:

Spindle motor: 5 H.P.

Wheel size: 12" Dia x 1.5" W x 5" B

Speed: 1,000 - 3,600 RPM

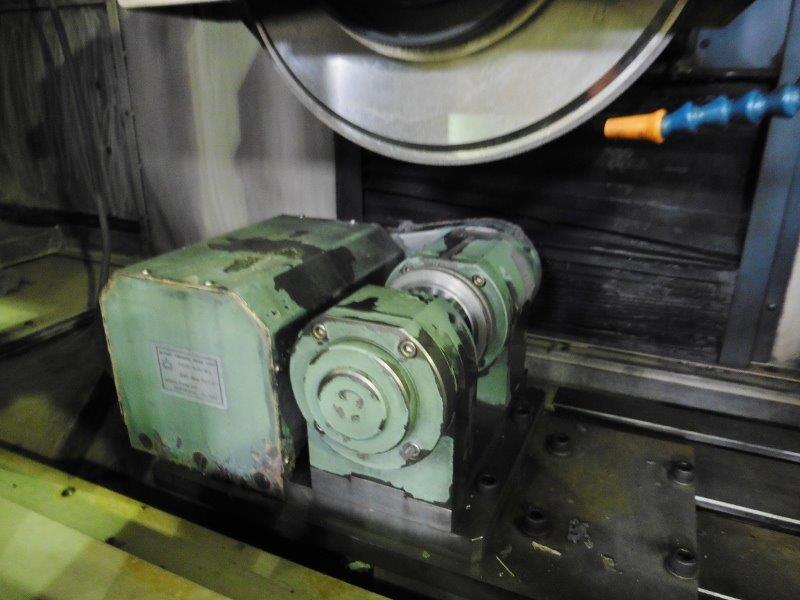

ASAHI Rdu-Wl Diamond rotary dresser

Oil temperature regulator unit

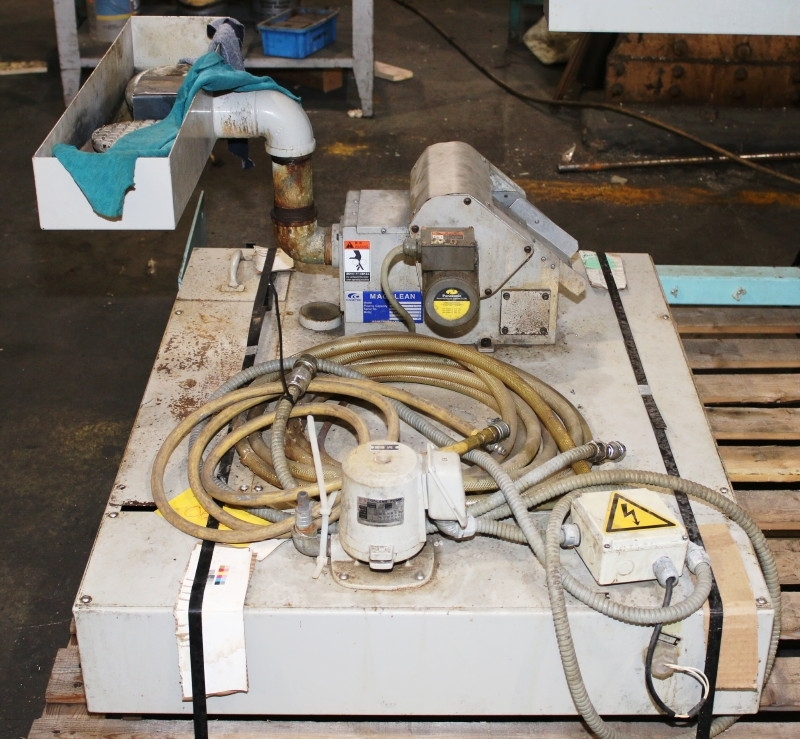

Coolant system with magnetic separator

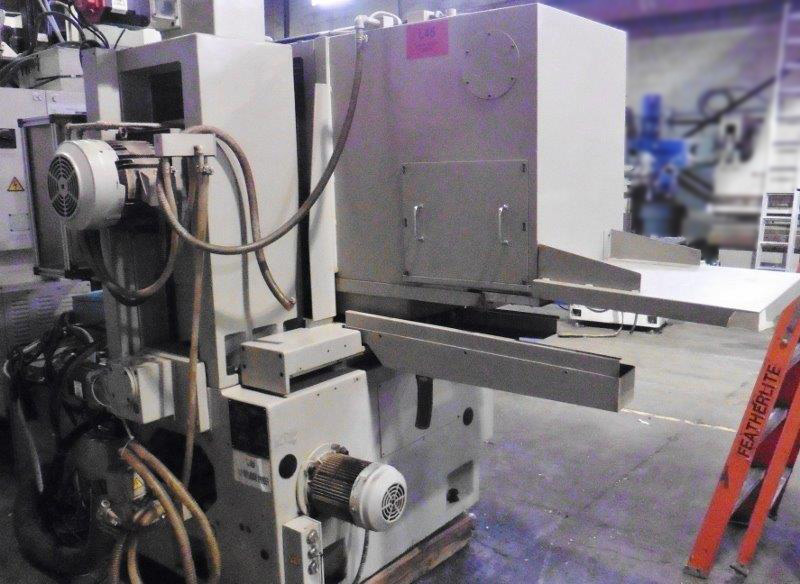

Machine tool enclosure

Case

Controlled axis: 2 Axis (2 SIM.)

3-Axis power operations

Minimum increment Y-axis (Vertical): 0.00001”

Z-Axis (Saddle): 0.00001”

Maximum programmable digits: ±8 Digits

Grind feed rate override: 0 - 150%

Rapid feed rate override: 0, 25, 50, 100%

Manual pulse feed increments: 0.00001, 0.0001, 0.001”

Preparatory functions: M-Codes (2-Digits)

Automatic acceleration / Deceleration

Manual continuous feed

Interpolation (Linear / Circular)

Dwell time

Machine lock

Skip function

Stored pitch error compensation

Dry run

Single block

Self-diagnosis function

Coordinate system setting

Pocket calculator type decimal point programming

Custom macro B (Option)

Inch / Metric conversion

Cutter compensation C

Input / Output interface: RS232C

Part program storage length: 262.5'

63-Registered programs

Built-in conversational programming system

Input programming system: Teach and drawing

Built-in conversational dress programming

Vertical and cross incremental feed

Automatic lubrication

Extended saddle and table ways

Double-walled column construction

Double vee way table and saddle construction

2007 vintage.

OKAMOTO ACC-12-24DXNCP is an innovative wafer grinding, lapping and polishing equipment, designed to increase the throughput and quality of your production process. Incorporating an angular grinding concept, ACC-12-24DXNCP allows for the simultaneous grinding of both sides of a glass or silicon wafer during one cycle within a single chamber. Capable of accommodating up to 24 wafers at one time, OKAMOTO ACC-12-24DXNCP utilizes several features to further enhance the grinding, lapping and polishing processes. For example, the system features a built-in coolant cutting fluids and adjustable rotational speed, to optimize grinding efficiency in accordance with a variety of wafers, different materials and user preferences. Furthermore, ACC-12-24DXNCP is equipped with an integrated and automated PLC (Programmable Logic Controller) grinding program, which offers dynamic precision and high-speed operations through the simple push-button control. The integrated touch-panel display provides easy access to unit parameters, allowing for easy processing and defect analysis. In order to further increase the user-friendliness, OKAMOTO ACC-12-24DXNCP is designed with vibration, noise and dust management features. These features incorporate a patented labyrinth structure, advanced fluid technology, and a rotational oil-free dry-air machine to minimize airborne dust and reduce product contamination, making it ideal for cleanroom environments. ACC-12-24DXNCP further enables high-level grinding and surface finish quality through advanced grinding/polishing methods such as Optimized Reflection and Advanced Pro-Diffraction Grinding/Polishing. Finally, the tool offers total process control and maintenance through multiple user modes, advanced process monitoring, and visualization systems. In conclusion, OKAMOTO ACC-12-24DXNCP is a comprehensive asset specifically designed to increase the throughput and quality of production in the grinding, lapping and polishing process. Offering a user-friendly and efficient interface coupled with various advanced grinding and polishing methods and maintenance features, ACC-12-24DXNCP is a reliable and cost-efficient option for many industrial applications.

There are no reviews yet