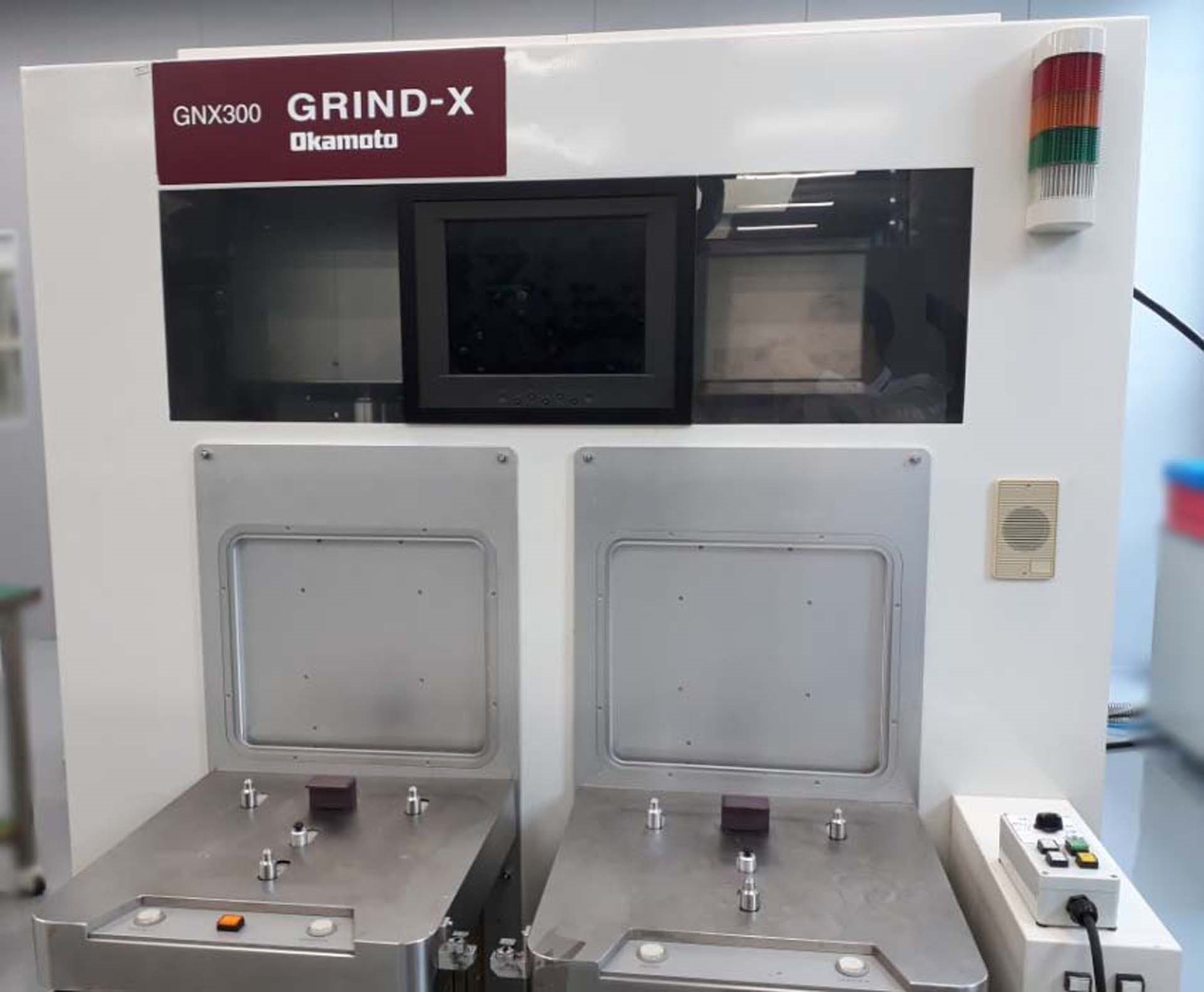

Used OKAMOTO GNX 300 #9039632 for sale

URL successfully copied!

Tap to zoom

ID: 9039632

Wafer Size: 8"-12"

Vintage: 2001

Wafer back grinder, 8"-12"

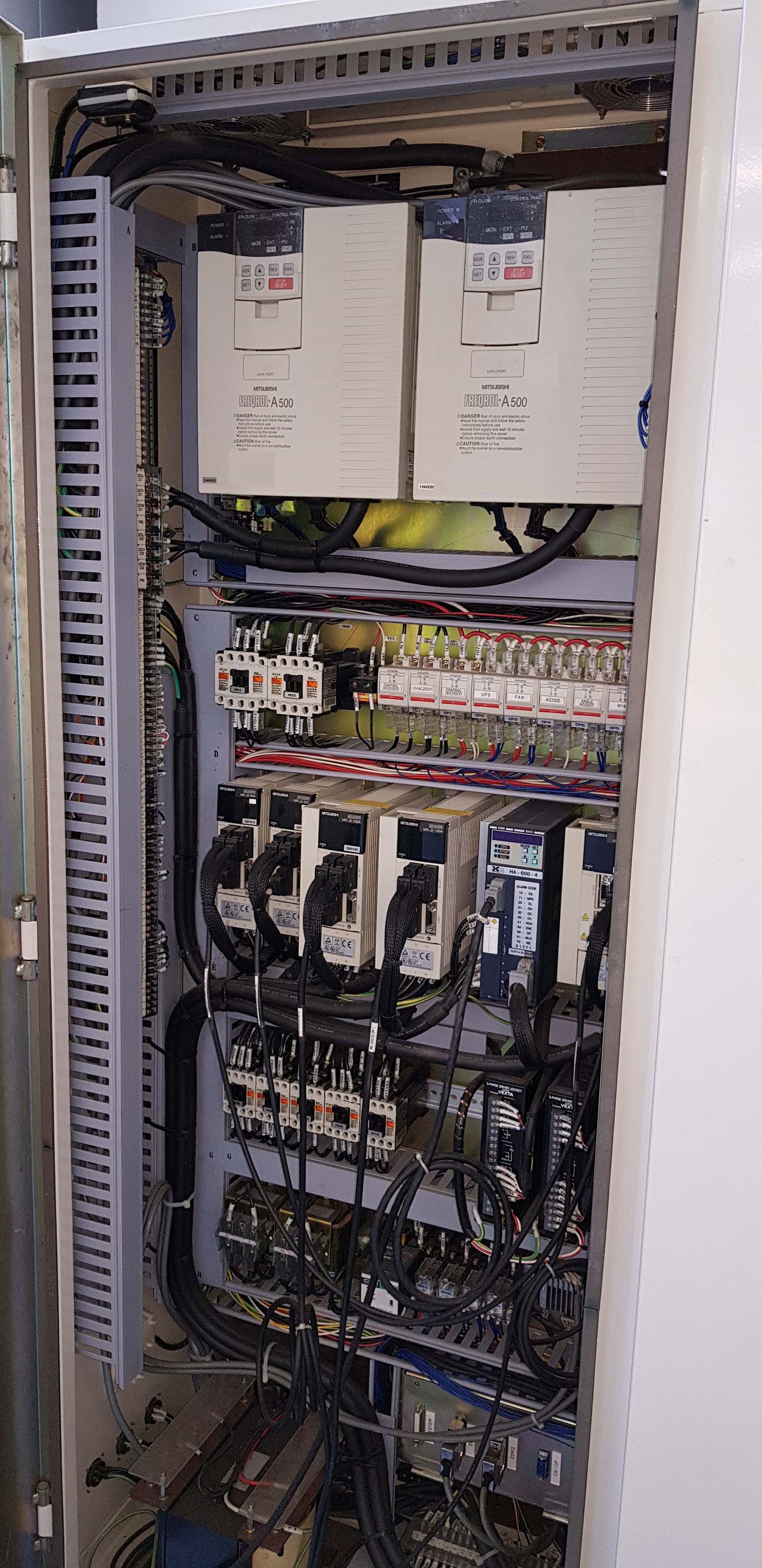

Grinding mode: Continuous down feed

2-Axes grinding spindle

Rotation speed: 3,000 RPM Maximum

Bearing: Air bearing

Motor: 5.5 kW built-in motor

Cooling method: Water cooled

Maximum vertical stroke: 4"

Vertical fast-grind speed: 8" per minute

Grinding speed: 1 to 999 um per minute

Grinder, 12"

Grinding resistance reading:

Monitoring current

Output to CRT

Horizontal angle adjustment: Manual

Maximum radial load capacity: 30 kgf

Maximum axial load capacity: 150 kgf

Air consumption: (2) 20 L per minute

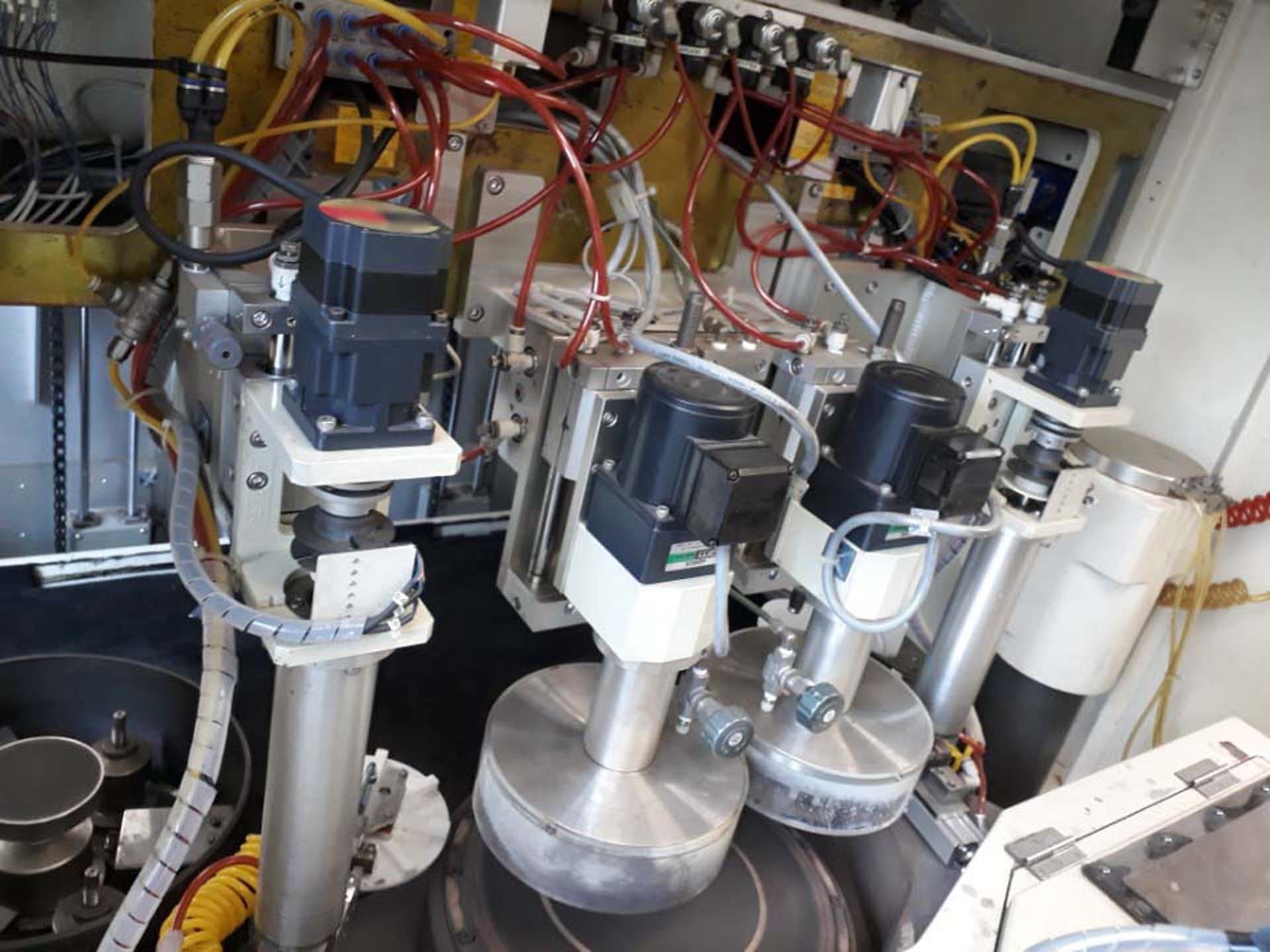

Index table:

(3) Vacuum chucks

Vacuum chuck material: Porous ceramic

Vacuum chuck rotation motor: (3) 1.0 kW AC Servo motors

Vacuum chuck rotation speed: 400 RPM Maximum

Chuck bearing: Air bearing

Maximum radial load capacity: 30 kgf

Maximum axial load capacity: 150 kgf

Air consumption: (3) 36 L per minute

Auto measuring device:

Wafer thickness measurement method: Two-point in-process gauge

Wafer thickness setting method: Final

Wafer thickness displaying range: 1.8 mm

Table cleaning unit:

Cleaning method: Water and ceramic ring

Wafer cleaning unit:

Cleaning method: Water and brush operation panel

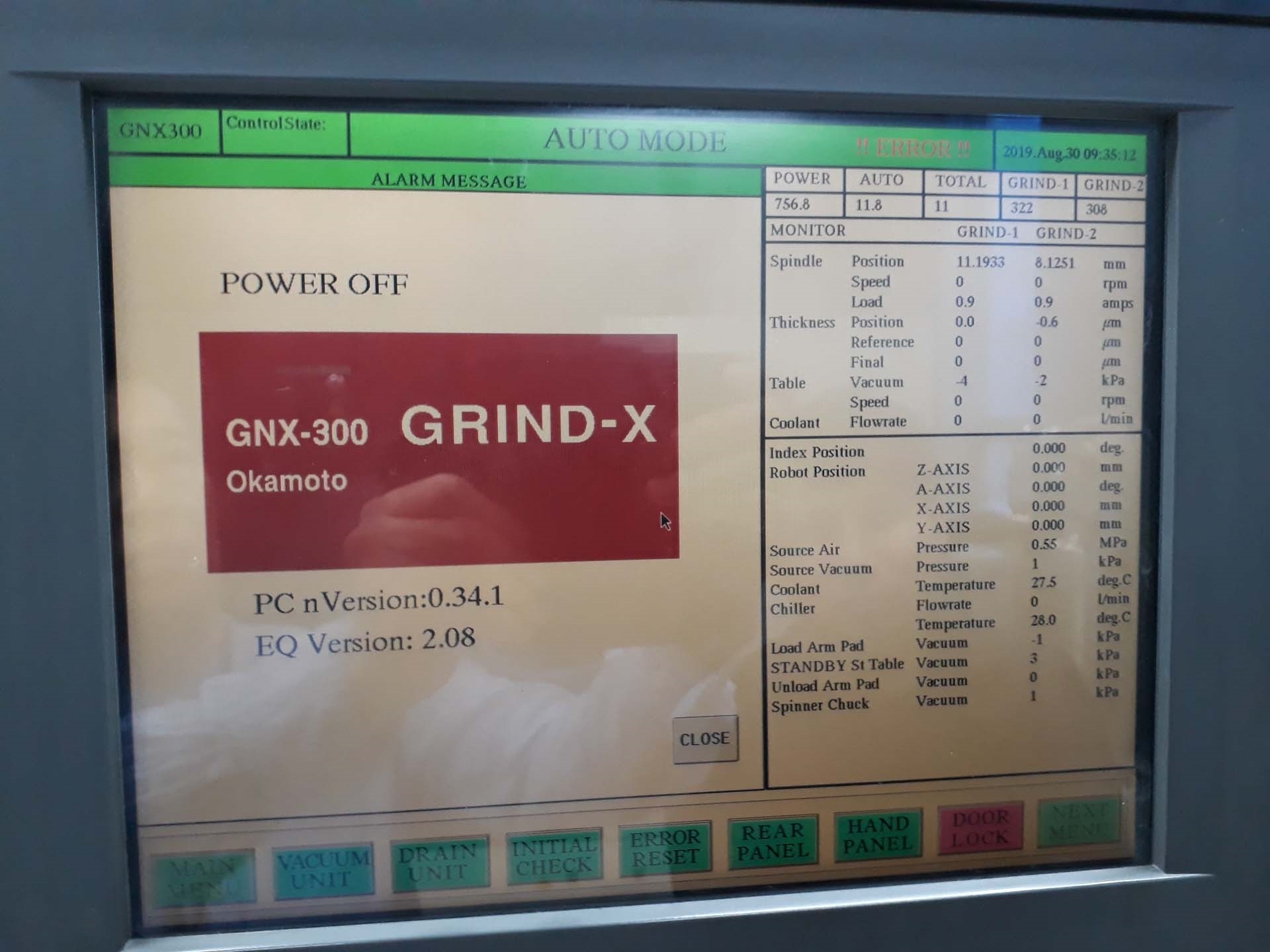

Display method: 15" TFT Color touch panel

Air supply:

Consumption: 160 NL Per minute

Pressure: 0.49 to 0.78 MPa

Dew point: -15°C or lower

Oil removal rate: 0.1 PPM W/W

Grinding water:

Water used: DI Water

Pressure: 0.34 to 0.49 MPa

Flow rate: 10 L per wafer

Cooling water for vacuum pumps and spindles:

Water used: City water

Pressure: 0.19 to 0.49 MPa

Flow rate: 10 NL Per minute

Mist separator duct / General exhaust:

Exhaust rate: 2 m³ per minute

Vacuum pump duct / General exhaust:

Exhaust rate: 75/90 m³/h, 50/60 Hz

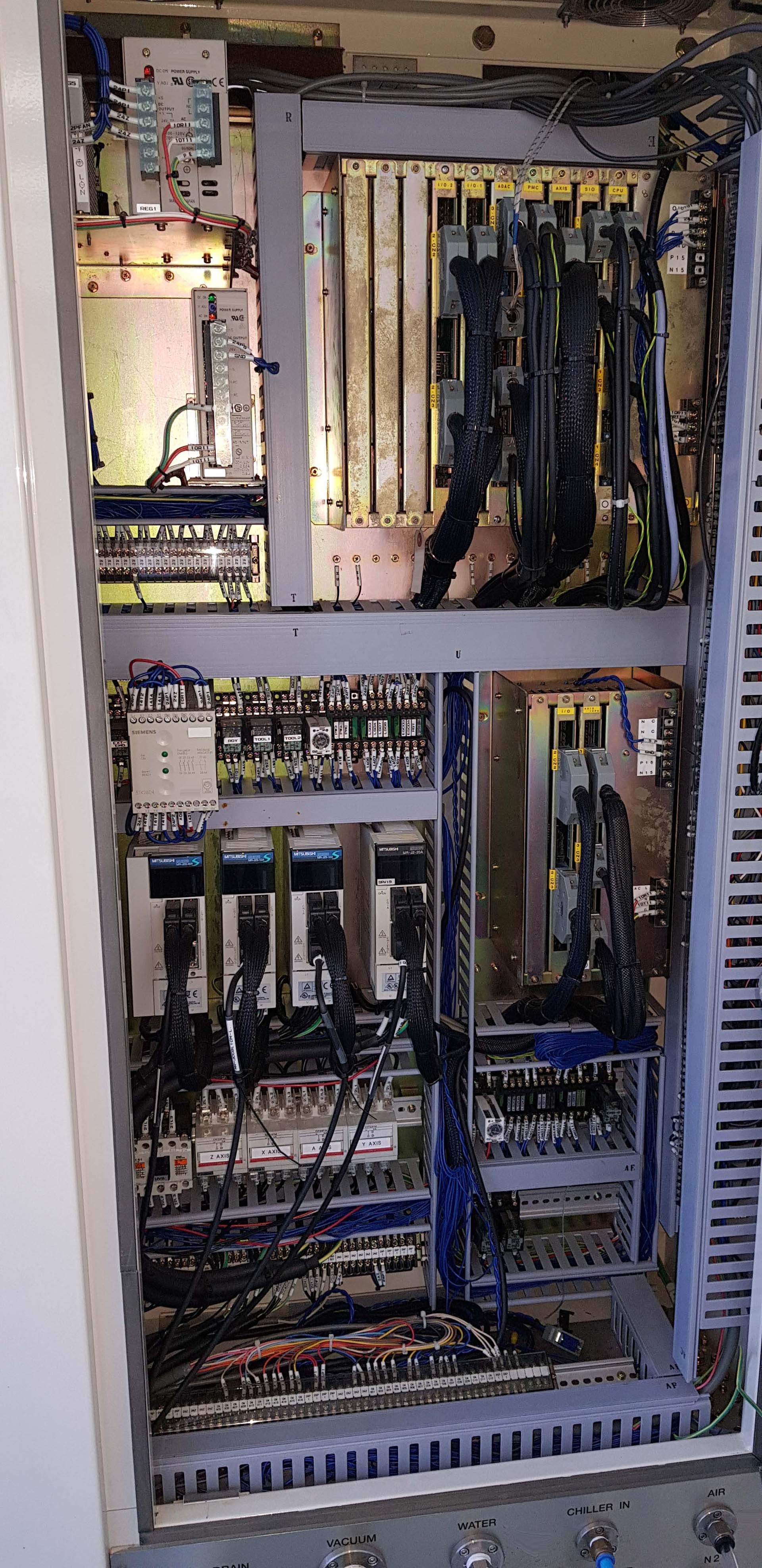

Power supply:

Input power: 200V +/- 10%, 3-Phase, 50/60 Hz

Power consumption: 20 kVA

Grounding: Ground resistance JIS Type-3 100 Ohms or lower

2001 vintage.

OKAMOTO GNX 300 is a state-of-the-art wafer grinding, lapping and polishing device. The machine is designed particularly for use in the semiconductor industry, as it offers high level of finish on both single and double-side double-layered wafers. This makes it ideal for the production of leading-edge integrated circuits. The machine features a powerful drive motor and planetary grinding discs that enable grinding of the semiconductor wafer to an extremely high degree of flatness and accuracy. The grinding discs have high concentricity, and can grind up to pieces with accuracy levels of 1¨ to 2µm. Additionally, the grinding discs can be adjusted in all directions for optimal pressing angles during the process. OKAMOTO GNX300 is equipped with two working heads, and each head can be individually adjusted for the pre-selected grinding angle of the wafer surface. This gives the operator superior control, and ensures uniform grinding quality. It can be used for wafers of different sizes. Furthermore, the machine is equipped with a spindle of variable speed range. This allows for both grinding and polishing operations to be carried out with higher precision. The spindle revs at up to 4,000rpm and ensures good process control when grinding and polishing. Moreover, the machine has built-in sensors that monitor load conditions during the process and protect the machine from any potential overload. This helps reduce downtime and helps keep the production running smoothly. The machine also incorporates an advanced wafer handling system. It has special handling fingers that gently gent and prevent damage caused during the grinding and polishing operation. It also has a low vacuum bar that maintains a low atmospheric pressure for better process control. The machine has a swing arm that helps easily move the wafers from the loading area to the process chamber, making the operation more efficient. Finally, the machine ships with advanced software which helps the operator closely monitor and control the grinding & polishing process. The software can be used to program the process, set slurry parameters, and monitor the process in real-time.Real-time monitoring of the process ensures consistent high-quality processes. In conclusion,GNX-300 is an advanced wafer grinding, lapping & polishing system that is capable to deliver accurate and consistent results for leading-edge integrated circuits. The machine combines powerful motor and planetary grinding discs to ensure grinding at high level of flatness and accuracy. It also features built-in sensors and an advanced wafer handling system for smoother operations.

There are no reviews yet