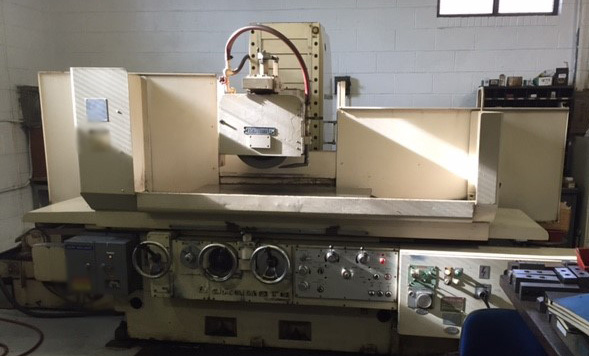

Used OKAMOTO PSG-126C #9124814 for sale

URL successfully copied!

Tap to zoom

ID: 9124814

Vintage: 1985

Automatic hydraulic surface grinder,

Incremental powered downfeed

23" x 47" Electro-magnetic chuck w/ controls

Hydraulic over-the-wheel dresser

Coolant system w/ filtration unit

Automatic lubrication system

Wheel balancing unit

1985 vintage.

OKAMOTO PSG-126C is a wafer grinding, lapping, and polishing equipment designed for precision sample preparation of ceramic, silicon, quartz substrates and other materials used in high-tech fields such as optoelectronics, microelectronics, and semiconductors. This system is designed to produce fine, uniform surface finish with a high degree of accuracy. The unit utilizes a rotary grinding wheel and high-precision linear feedback servo drive technology to accurately and quickly grind two sides of the wafer sample at once. The grinding wheel is designed to provide a single, flat grinding plateau that ensures equal amount of grinding pressure on all samples. The wheel rotates at a controlled speed and can be adjusted to grind different materials at various angles and speeds. The resulting samples are highly uniform and defect free. The machine also comes with a precision lapping and polishing subsystem that is tailored to the grinding wheel and can be integrated into or operated separately from the grinding wheel tool. It utilizes an adjustable magnetic chuck and an air bearing carriage which accurately moves the wheel over the sample. This provides for extremely consistent lapping and polishing results across all wafer samples. PSG-126C is designed with user-friendly features such as a touch-screen interface and a range of process parameters that can be set up to meet specific application needs. This asset also provides precision feedback data so that the user can monitor the progress of the grinding and polishing operation. OKAMOTO PSG-126C is an effective tool for precision wafer grinding, lapping and polishing that provides both accuracy and repeatability. Its user-friendly interface, highly precise motion control model, and adjustable process parameters make it an ideal choice for many wafer processing applications.

There are no reviews yet