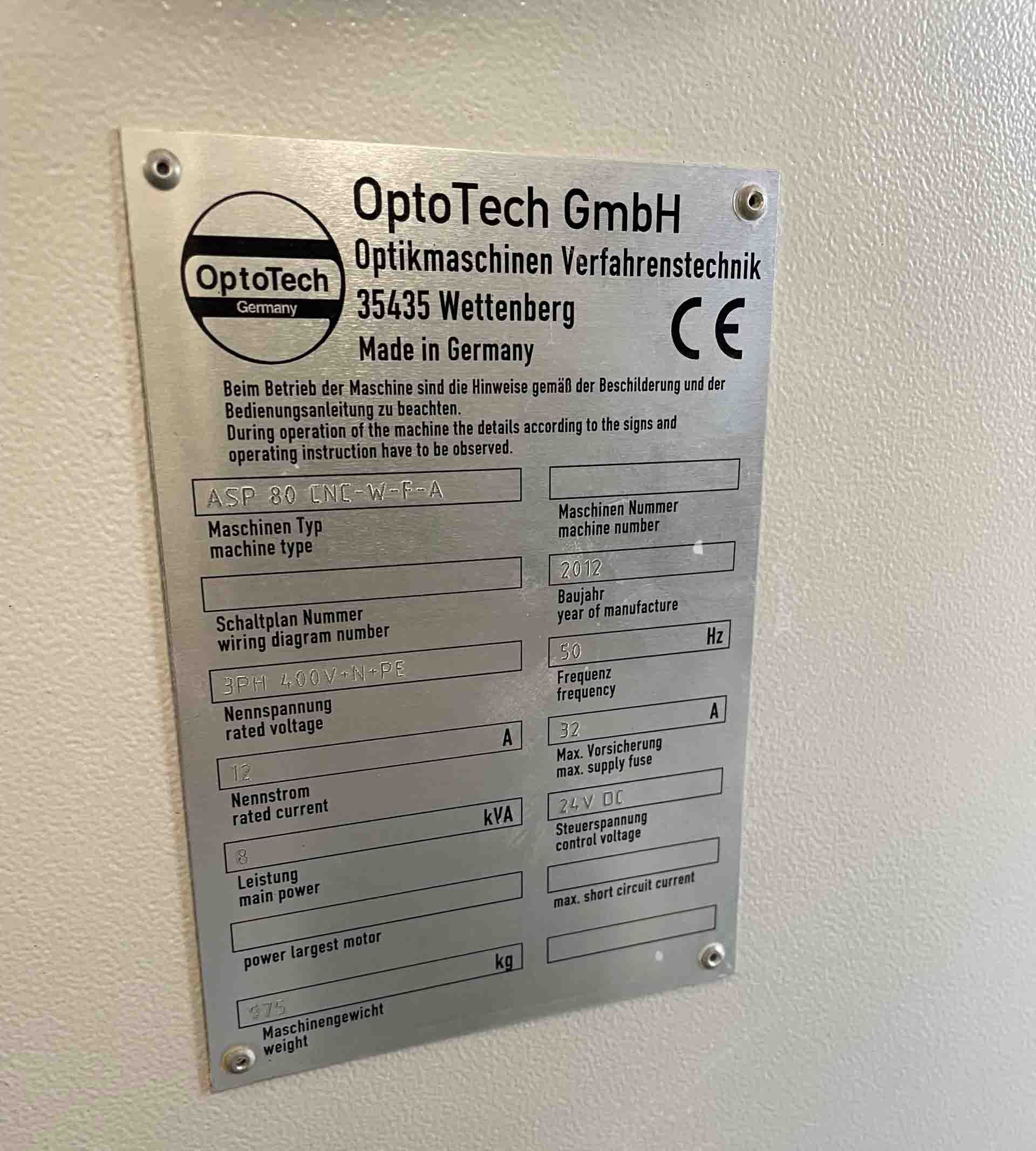

Used OPTOTECH ASP 80 CNC-W-F-A #293597594 for sale

URL successfully copied!

Tap to zoom

OPTOTECH ASP 80 CNC-W-F-A is a fully automated, CNC-Calculated, robust and reliable Wafer Grinding, Lapping & Polishing equipment designed to automatically grind, lap and polish wafers with precision and repeatability. The system uses a CNC controller with a computer-controlled drive unit, as well as an advanced linear motor technology driven by a regenerative position feedback machine. This ensures a controlled focusing and ultrashort cycle times. The tool can process up to three wafers at a time. ASP 80 CNC-W-F-A utilizes an in-situ measuring asset to automatically monitor each wafer precisely and accurately during the grinding, lapping and polishing process. A touch-screen panel with intuitive and user friendly software is used to program the operation, machine settings and measurement functions. The model includes a low-profile encoder which tracks the exact position of the grinding and lapping tools along the circumference and maintains the full-width of process window. OPTOTECH ASP 80 CNC-W-F-A also features a specialized loading station which can accommodate 300 mm wafers, as well as non-standard wafers such as 300 mm square wafers. A flexure mechanism enables adjusting the preload force on any wafer to prevent damage and reduce chatter during the lapping process. The equipment has a highly adjustable spindle speed up to 10,000 rpm and a diamond-coated belt system for polishing. ASP 80 CNC-W-F-A has a unique vision-based in-situ metrology unit which ensures the highest level of 2D and 3D topography accuracy. The machine is capable of detecting and automatically correcting any irregularities, enabling the wafer to achieve exact specifications quickly and efficiently. The vision-based metrology tool also has the ability to receive external data, allowing remote monitoring and optimization of the process. The asset is capable of handling different diamond combinations with each diamond type placed in the exact position and orientation necessary for the most effective wafer finishing. It also has a built-in safety feature which helps protect the wafers during the grinding, lapping and polishing processes. OPTOTECH ASP 80 CNC-W-F-A is a highly advanced wafer grinding, lapping and polishing model designed to create high quality parts in a highly efficient manner. It is capable of processing multiple batches of three wafers quickly and accurately. The equipment features a highly adjustable spindle speed and a specialized loading station, as well as a vision-based in-situ metrology system for precise 2D and 3D topography measurements. This CNC-Calculated unit provides repeatable, reliable and accurate results.

There are no reviews yet