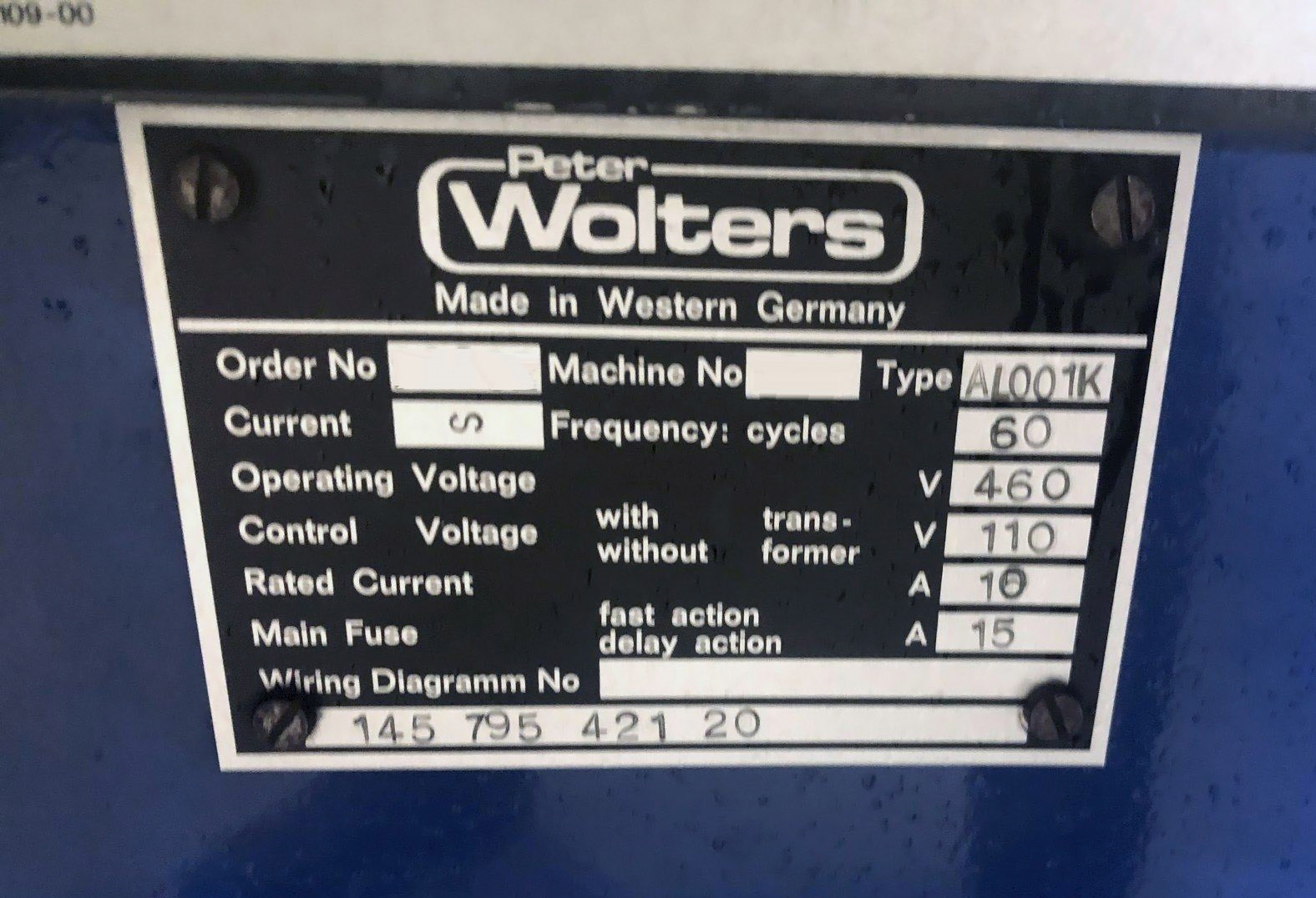

Used PETER WOLTERS AL001K #9276313 for sale

URL successfully copied!

Tap to zoom

ID: 9276313

Double sided grinding and lapping machine

Lapping wheels: 12.2" x 3.83"

Upper wheel speeds: 14 / 28 RPM

Lower wheel: 24 / 54 RPM

Wheel drive: .87 kW

Pin type: Epicyclic work drive

Workpiece drive: 27 / 54 RPM

With reversing

(2) Speed lapping wheels

Cycle timer

Abrasive grinding wheels

Pneumatic adjustable operating pressure.

PETER WOLTERS AL001K is a high-precision, automated equipment designed for wafer grinding, lapping and polishing. As part of an Automatic Lapping and Polishing System, this unit is designed to provide users with superior rates of wafer grinding, lapping and polishing that meet stringent standards. This machine is widely used by manufacturers of semiconductor components and other specialized applications as it provides superior rigidity, accuracy and flexibility. The machine is designed to be fast, efficient and reliable for a variety of polishing and grinding applications. AL001K is constructed with a rigid steel frame, and features a high speed, accuracy and repeatability that are essential for successful wafer grinding, lapping and polishing processes. The tool features advanced digital servo-motors that are designed to ensure smooth and precise movements of the grinding, lapping and polishing heads. In addition, the machine is equipped with closed loop speed control, allowing users to precisely control the positioning and speed of the grinding, lapping and polishing heads. PETER WOLTERS AL001K also features an integrated three-axis manipulator, allowing the user to quickly and accurately place wafers into the grinding, lapping and polishing processes. This feature enables users to perform multiple passes, helping increase rates of material removal. Furthermore, the integrated three-axis manipulator can be easily reprogrammed and re-calibrated in minutes to adapt to different materials and different process steps. The asset also features a proprietary vibration resistant environmental enclosure that minimizes unwanted noise and vibration, helping to ensure consistent and accurate performance. This also helps to reduce consumption of chemicals and abrasives, further increasing the model's efficiency and cost effectiveness. AL001K is designed with user convenience and safety in mind. It features advanced sensors and software that help to ensure a safe and user-friendly experience. Some of these features include a full range of alarms and warnings that alert users to potential hazards, and an automatic shut-off protocol that automatically stops any hazardous machine movements from occurring. Overall, PETER WOLTERS AL001K is an advanced and reliable wafer grinding, lapping and polishing equipment that is designed to provide users with a highly efficient system for producing superior quality components in a cost-effective manner. This unit is equipped with advanced digital servo-motors, precise control systems, an integrated three-axis manipulator and vibration resistant environmental enclosure, all of which combine together to form a comprehensive and highly effective machine for wafer grinding, lapping and polishing.

There are no reviews yet