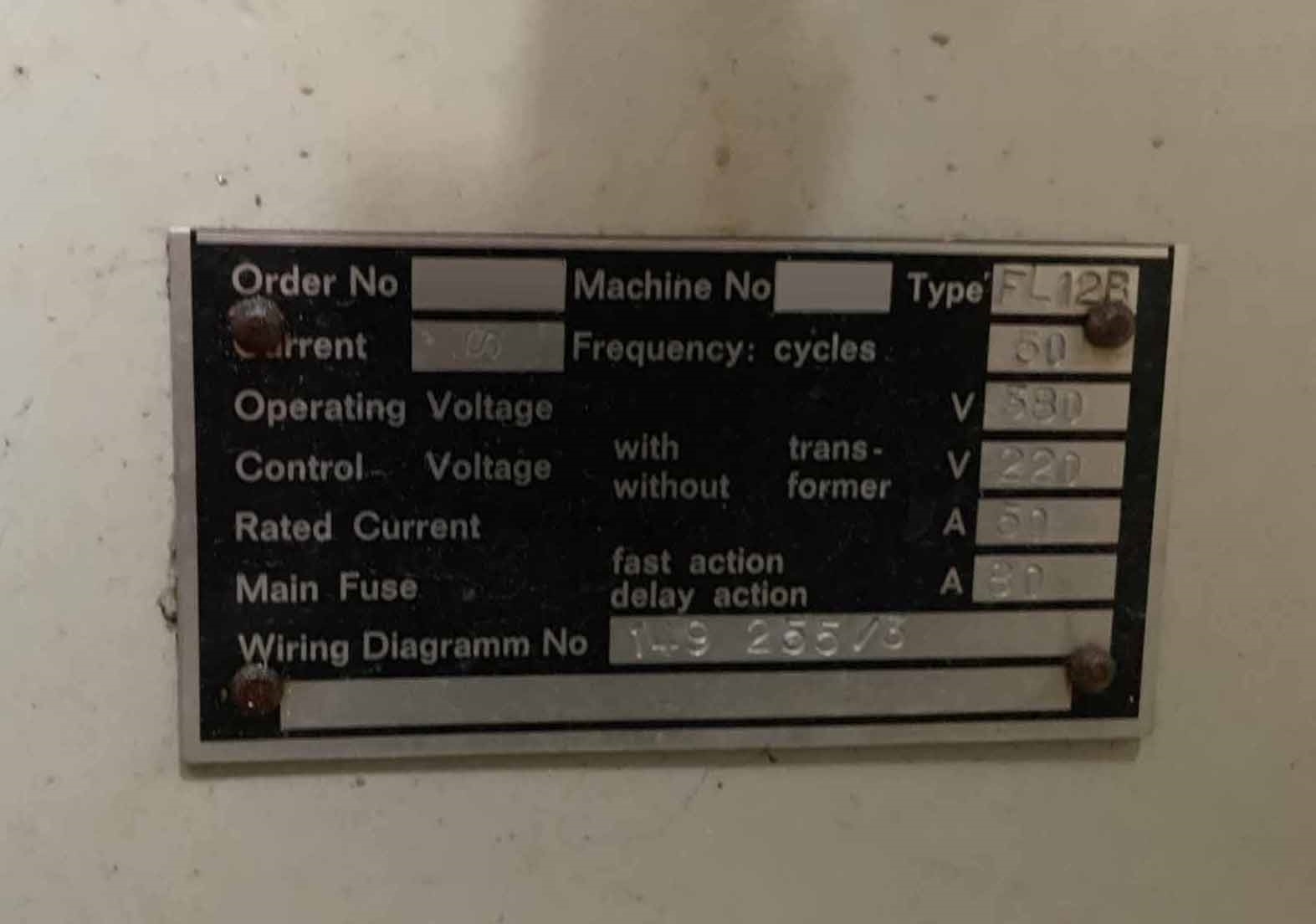

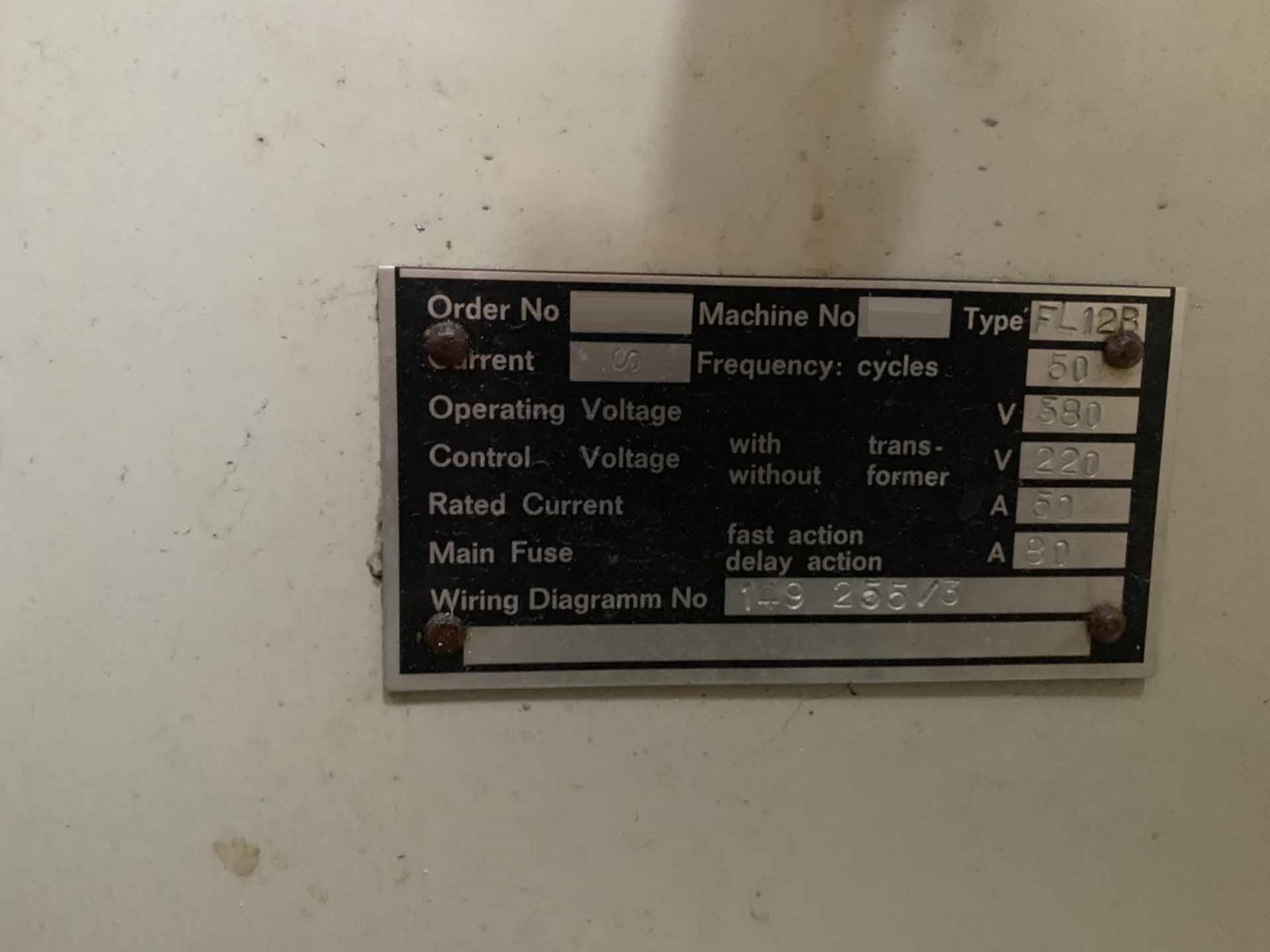

Used PETER WOLTERS FL 12B #144788 for sale

URL successfully copied!

Tap to zoom

ID: 144788

Vintage: 1988

Grinding machine

For lapping of aluminum plates

Diameter of wheel: 1300 mm

Diameter of plates: 480 mm

(4) Plates

Power: 380/220 V, 50 A, 50 Hz

1988 vintage.

PETER WOLTERS FL 12B grinding and polishing equipment is a full-fledged wafer grinding, lapping and polishing process. It is a single machine system perfect for handling a wide range of applications and materials. The unit features a 3-axis robot table with a maximum traverse length of 500mm and a maximum stroke of 200mm allowing for precise motion over complex workpieces. The machine is integrated with a 10-station air bearing turret for secure grasping and handling of both wafers and substrates. The tooling turret is equipped with 6 tool holders with at least two tools per station allowing for multi-surface grinding and polishing operations. The tool is also equipped with two wafer chuck stations, one for 200mm wafers and one for 150mm wafers, allowing for secure handling and precise motion control over thin, complex workpieces. The grinding and polishing asset is designed for precise and repeatable grinding, lapping and polishing operations. The model has a maximum rotational speed of 3,000 rpm and a maximum acceleration of 5G, which allows for precise grinding and polishing of a wide range of materials. For accurate grinding and polishing of a variety of materials, the equipment is equipped with a range of polishing fixtures with adjustable depth, angle, and pressure settings as well as customised pressure profiles. The system also features a water-cooling unit which helps maintain low temperatures and reduce thermal damage during the grinding and polishing process. In addition, the machine can be automated for unmanned operation for longer periods of time, enabling faster manufacturing throughput and improved accuracy. The integrated robot controller allows the user to program and store grinding and polishing profiles within the machine, meaning changes can be made quickly and conveniently. FL 12B also includes extensive safety features to ensure that operation is safe and secure. It has several safety sensors, including a laser safety tool, and a cover opening sensor which allows it to be safely operated even when a cover is open. PETER WOLTERS FL 12B grinding and polishing asset is an excellent choice for precise, repeatable grinding and polishing of complex workpieces. With its range of grinding fixtures and tool holders and integrated water-cooling model, it is the perfect choice for a variety of grinding and polishing applications. The integrated robot table with 10-station air bearing turret allows for precise motion control and secure handling, and the automated operation mode makes repetitive grinding and polishing operations fast and easy. The built-in safety systems make it one of the safest machines available for production.

There are no reviews yet