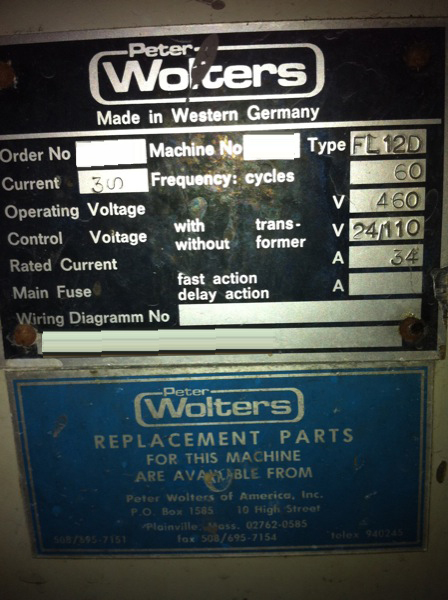

Used PETER WOLTERS FL 12D #103671 for sale

URL successfully copied!

Tap to zoom

PETER WOLTERS FL 12D is a fully automated, high-precision wafer grinding, lapping and polishing equipment designed for fine finishing surfaces for various materials such as silicon, quartz, and glass. The system offers an automated surface conditioning process to generate the highest quality fine-ground surface finish possible. The wafer grinding unit is powered by a 1.1Kw 3 phase motor that drives two 1.2 mm grinding belts to achieve superior surface grinding and lapping on complex parts. The machine utilizes a unique 2 phase cycle that provides uniform polishing and a high level of surface finish accuracy. The two-phase cycle consists of a grinding phase and a polishing phase, with the grinding phase taking place first. In the grinding phase, two separate grinding belts move at high speed over the surface of the part to be finished, in order to remove material and achieve a rough surface finish. The polishing phase then takes place, in order to smooth out the rough surface finish generated by the grinding phase. In addition to its grinding and lapping capabilities, the tool also offers a wide range of automated polishing options, including spray mist conditioning, vibratory polishing, slurry conditioning, scrubbing and dry polishing. The asset is designed to be easily adaptable to various materials, including silicon and quartz wafers, as well as other materials like ceramic and sapphire. As well as performing surface treatment and grinding, FL 12D also offers integrated solutions for optical inspection and metrology. The model includes a built-in optical microscope with a high level of accuracy in order to inspect surfaces of parts before and after they are treated. This enables the equipment to provide an objective quality assessment of the finished parts and help the user to optimize processes accordingly. PETER WOLTERS FL 12D is the ideal wafer grinding, lapping and polishing system for applications that require high levels of accuracy and surface finish quality, as it is capable of delivering superior levels of automation and metrology. The unit is also extremely versatile, allowing it to be used with a wide range of materials, providing users with multiple ways to produce a high quality finished part.

There are no reviews yet