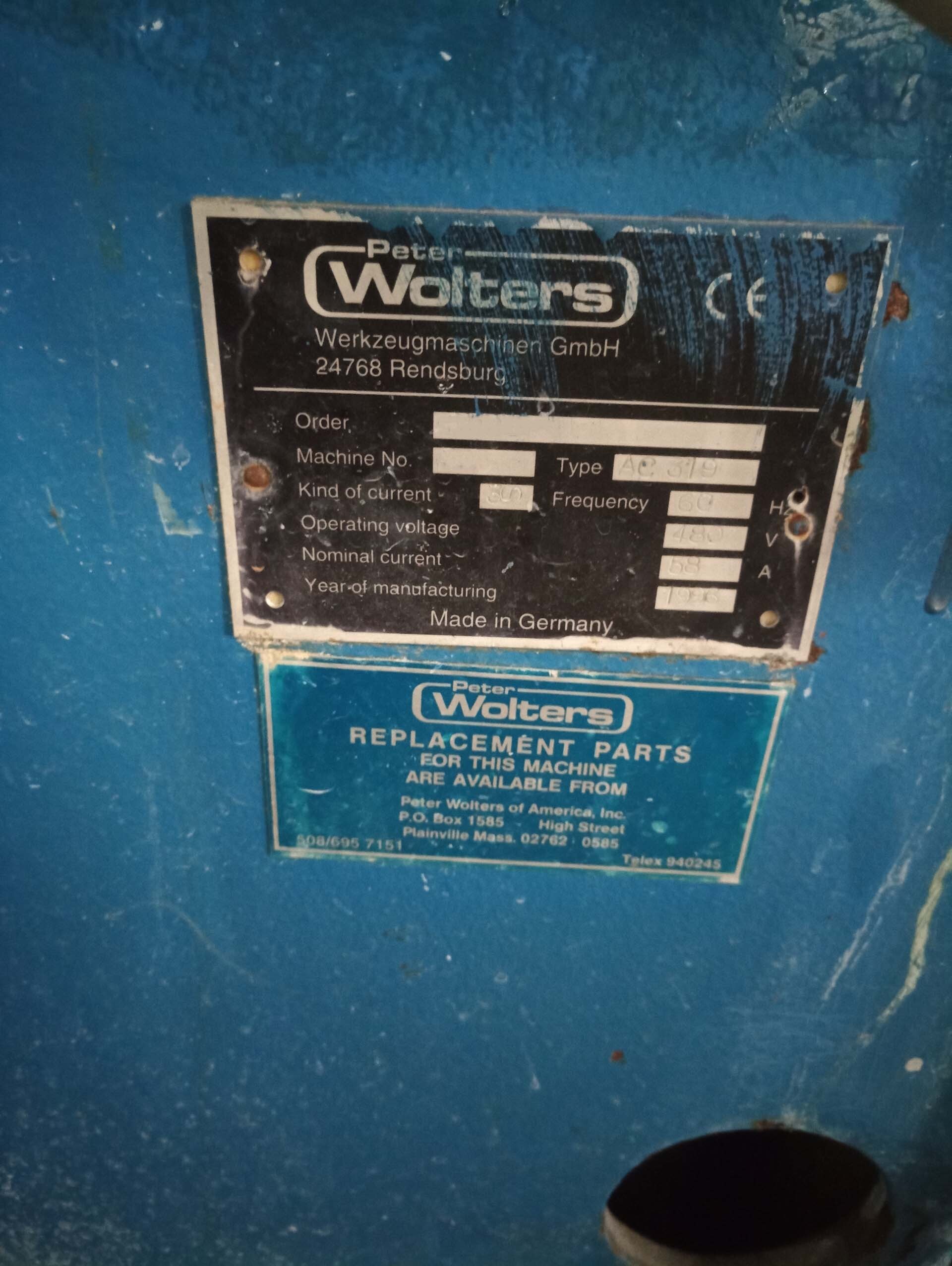

Used PETER WOLTERS MicroLine AC 319 #9401240 for sale

URL successfully copied!

Tap to zoom

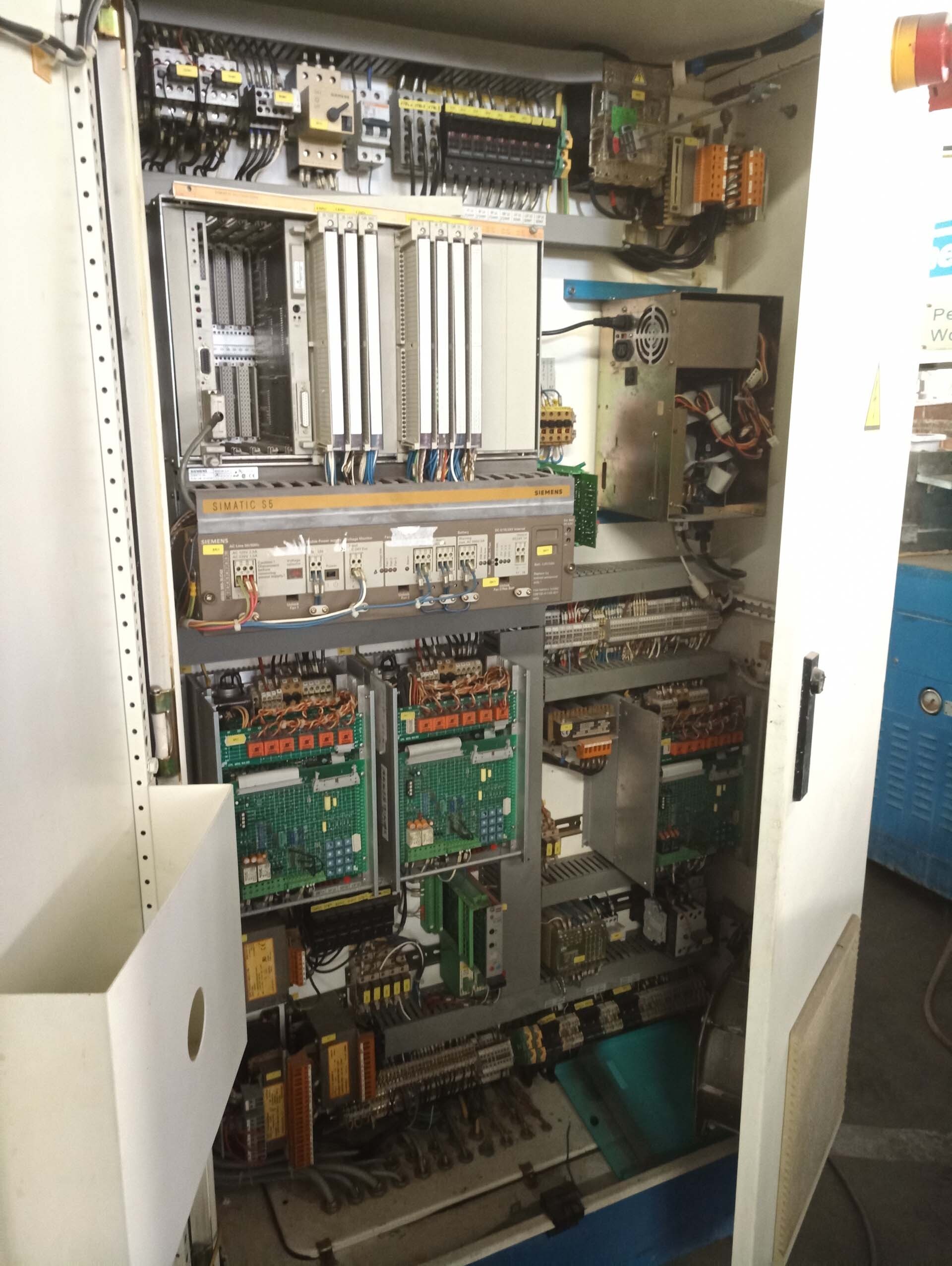

PETER WOLTERS MicroLine AC 319 is a precision grinding and polishing equipment for wafer manufacturing. This automated multi-axis system delivers high accuracy surface preparation and high production rates with repeatability and low operator intervention. It is designed for grinding, lapping and polishing operations of one or more silicon wafers per processing cycle. The unit is equipped with an inverted microscope that is integrated with measuring base station, allowing for precision grinding and polishing of wafers. The machine offers a closed loop process with closed loop feedback control on the grinding and polishing spindles. It is programmable by a PC with a touch panel and can easily be operated in single or automatic mode. The machine also features an innovative retooling station which allows for quick changeover of grinding and polishing tools. MicroLine AC 319 has built-in temperature control and maintains the desired temperature accurately, even with high output spindle power. The tool is equipped with precision end-effectors and workholding devices, enabling it to adapt to a variety of substrates and features a 'smart touch" asset, which recognizes the size and thickness of the silicon wafer being processed and adjusts the process to achieve the desired results. The model also offers high-speed part transfer, multiple tool heads for lapping, grind and polishing operations, and a variety of options for different wafer production requirements. Additionally, the equipment can be configured with options for post grinding cleaning with all the necessary parts and tools. Lastly, the system is designed to be ergonomic, allowing operators to load and unload wafers in the shortest amount of time possible. In conclusion, PETER WOLTERS MicroLine AC 319 is an ideal precision grinding and polishing unit for wafer manufacturing, offering high accuracy and repeatability and greatly reducing the need for operator intervention. The machine features a range of features to enable high production rates with maximum output and accuracy, while maintaining the desired temperature. Additionally, this automated multi-axis tool is configurable with a range of options and post processing cleaning, making it a reliable, cost-effective solution for wafer production.

There are no reviews yet