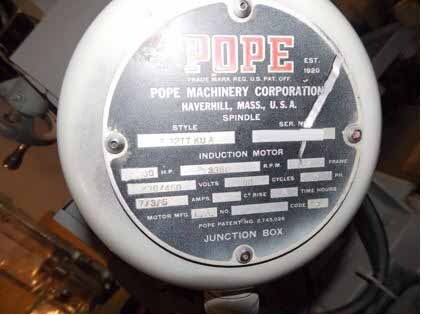

Used POPE P 32TT KUA #9149623 for sale

URL successfully copied!

Tap to zoom

The Wafer Grinding, Lapping & Polishing System POPE P 32TT KUA, manufactured by Peter Wolters GmbH, is an automated machine specifically designed for grinding, lapping and polishing wafers in the semiconductor industry. It is used to deburr and process of the thin-film layers of the wafers during lithography or ion implantation. P 32TT KUA features a modular and compact design, small exterior dimensions, and robust construction. It is well equipped for handling high accuracy and long-term repeatability. The machine includes a main diamond grinding wheel unit with an integrated rotary cross-feed spindle. The spindle delivers a high surface quality with low vibration and a high flexibility in configuration of the process parameters. The spindle movement is driven by a direct drive motor with a high precision servo control, and is perfectly suitable for high speed processes. The grinding wheel unit on POPE P 32TT KUA is mounted on a high-precision spindle system allowing a very short setup time and easy tool changeover. The system includes a rotating tool holder for rapid wheel switching, a wide range of abrasives, and adjustable wheel speeds of up to 2,000 rpm. It also provides a profile tracker for grinding wheel profiling, which is a valuable tool for maintaining precise wafer characteristics. P 32TT KUA is also equipped with a vertical lap base, allowing for lapping and fine polishing of various substrates. The lap base includes an integrated evaporator for reconditioning of the lapping surface. It is also integrated with a high-precision linear drive, allowing for minimal vibration and high positioning accuracy. Additionally, POPE P 32TT KUA is equipped with a platen supply and take-up unit, which allows for grinding, lapping, and polishing of substrates that are larger than usual. P 32TT KUA is a high-precision, industrial machine with excellent performance. It offers a robust design, high-precision servo-controls, and a high-speed spindle that guarantee optimal processing, even with tight tolerances. Its variety of upgrade and configuration options allow for precise handling and quick processing of any type of wafer.

There are no reviews yet