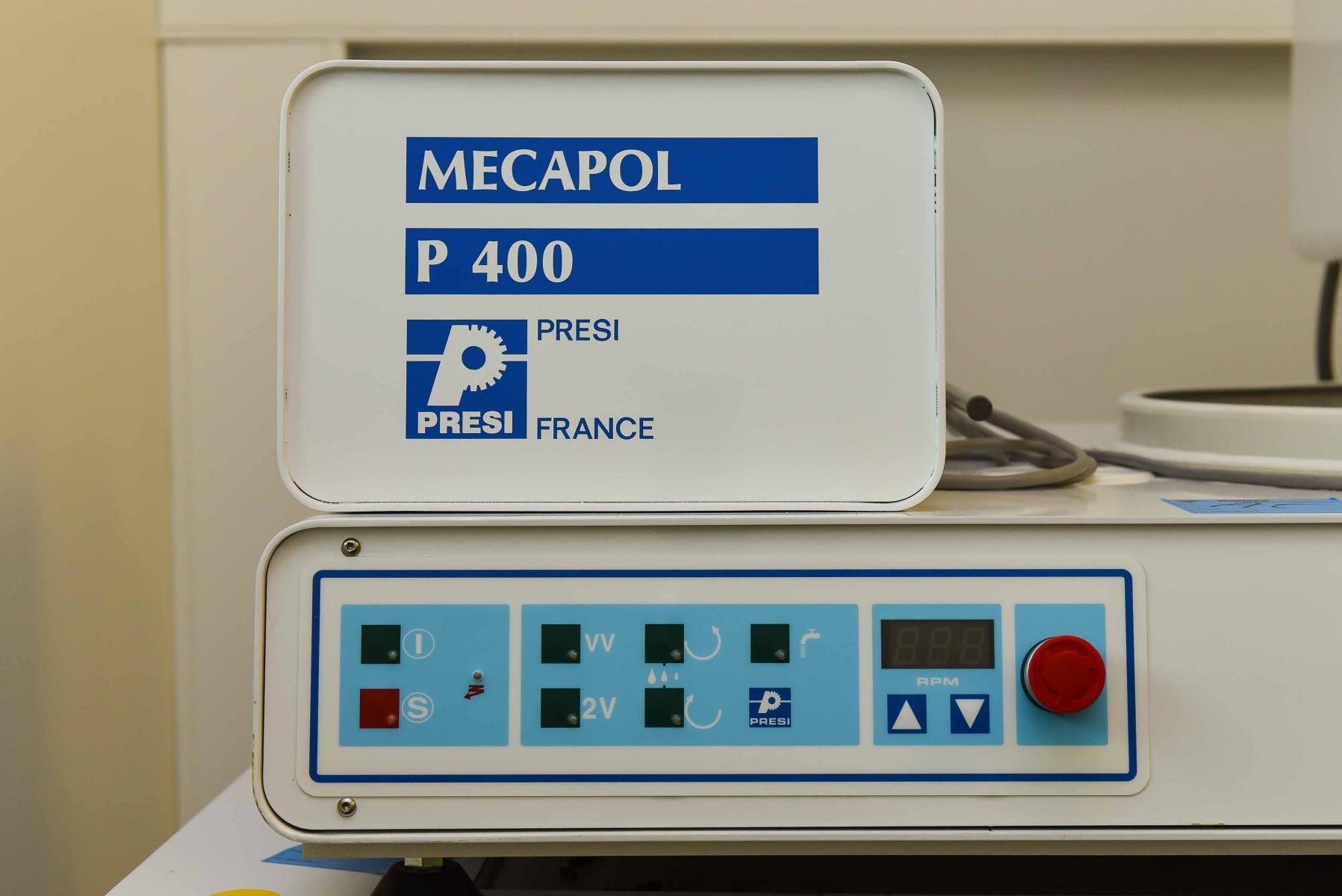

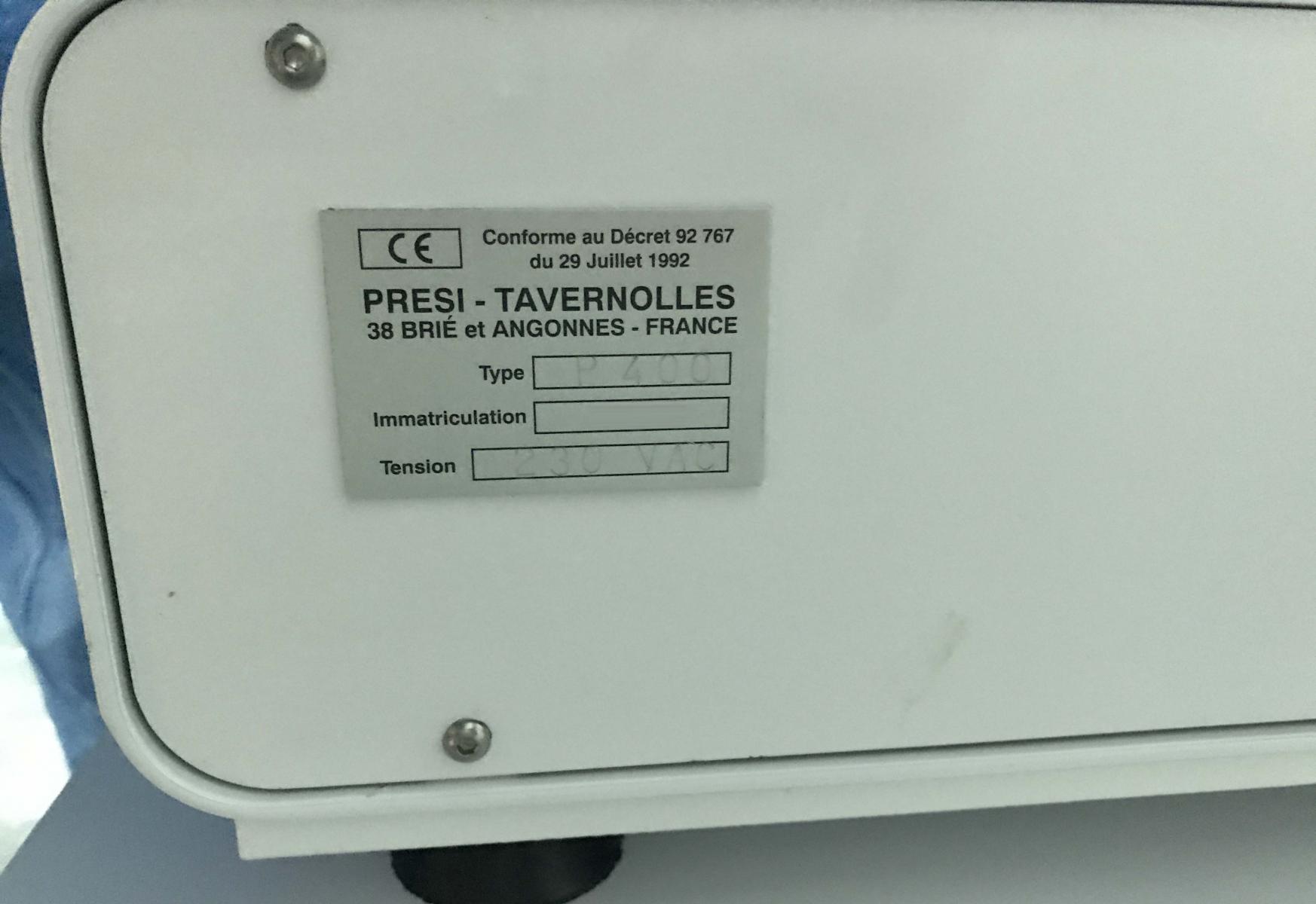

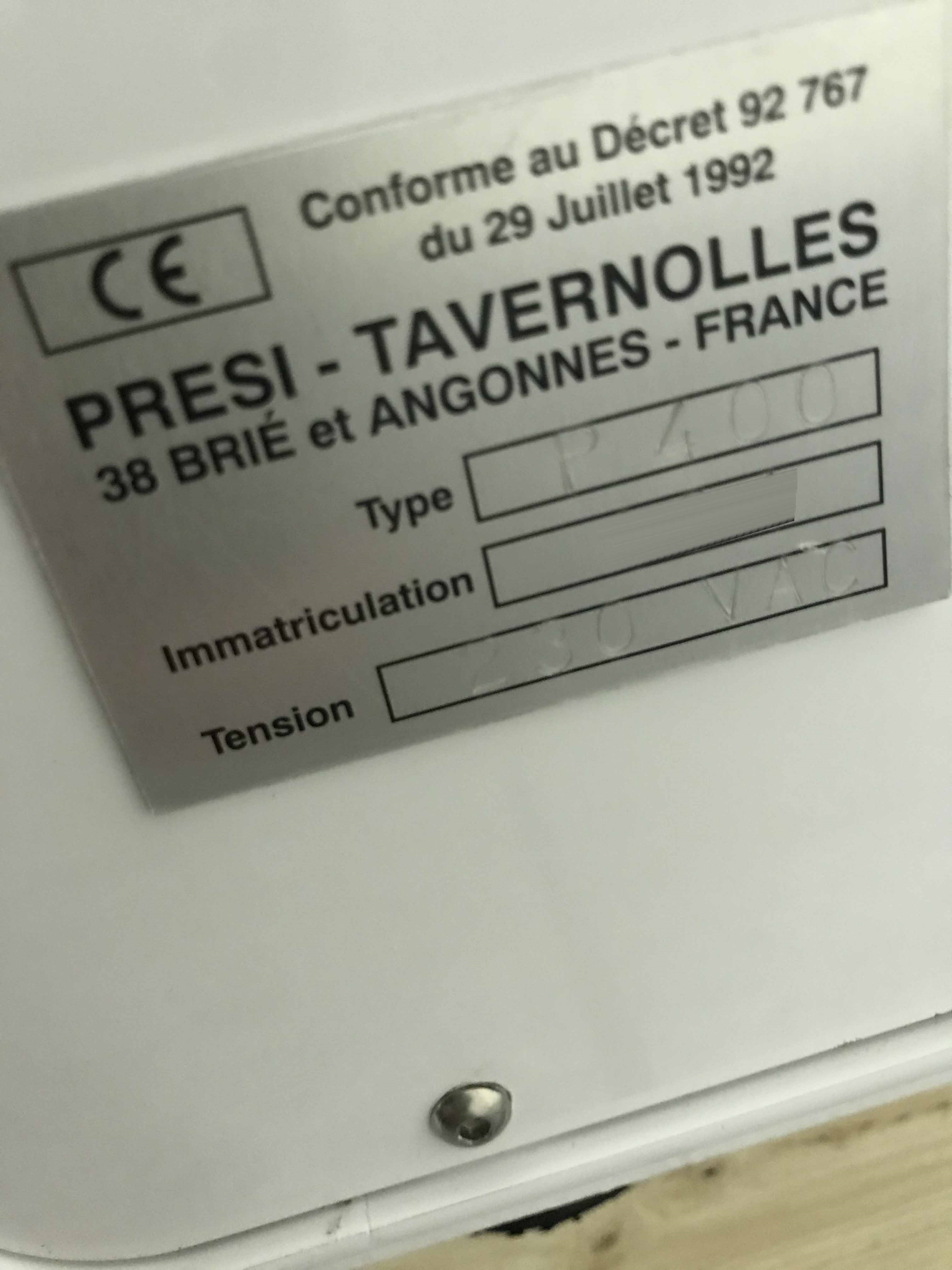

Used PRESI MECAPOL P 400 #9182845 for sale

URL successfully copied!

Tap to zoom

ID: 9182845

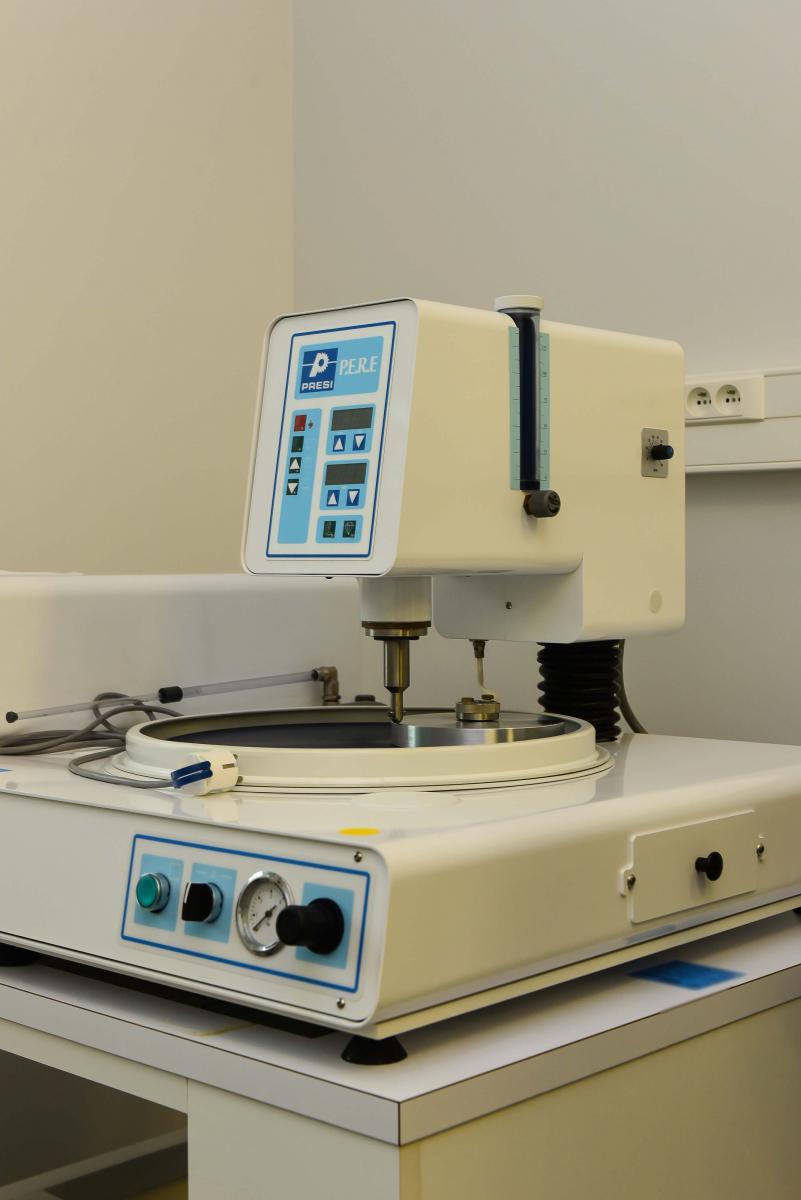

Polishing machine

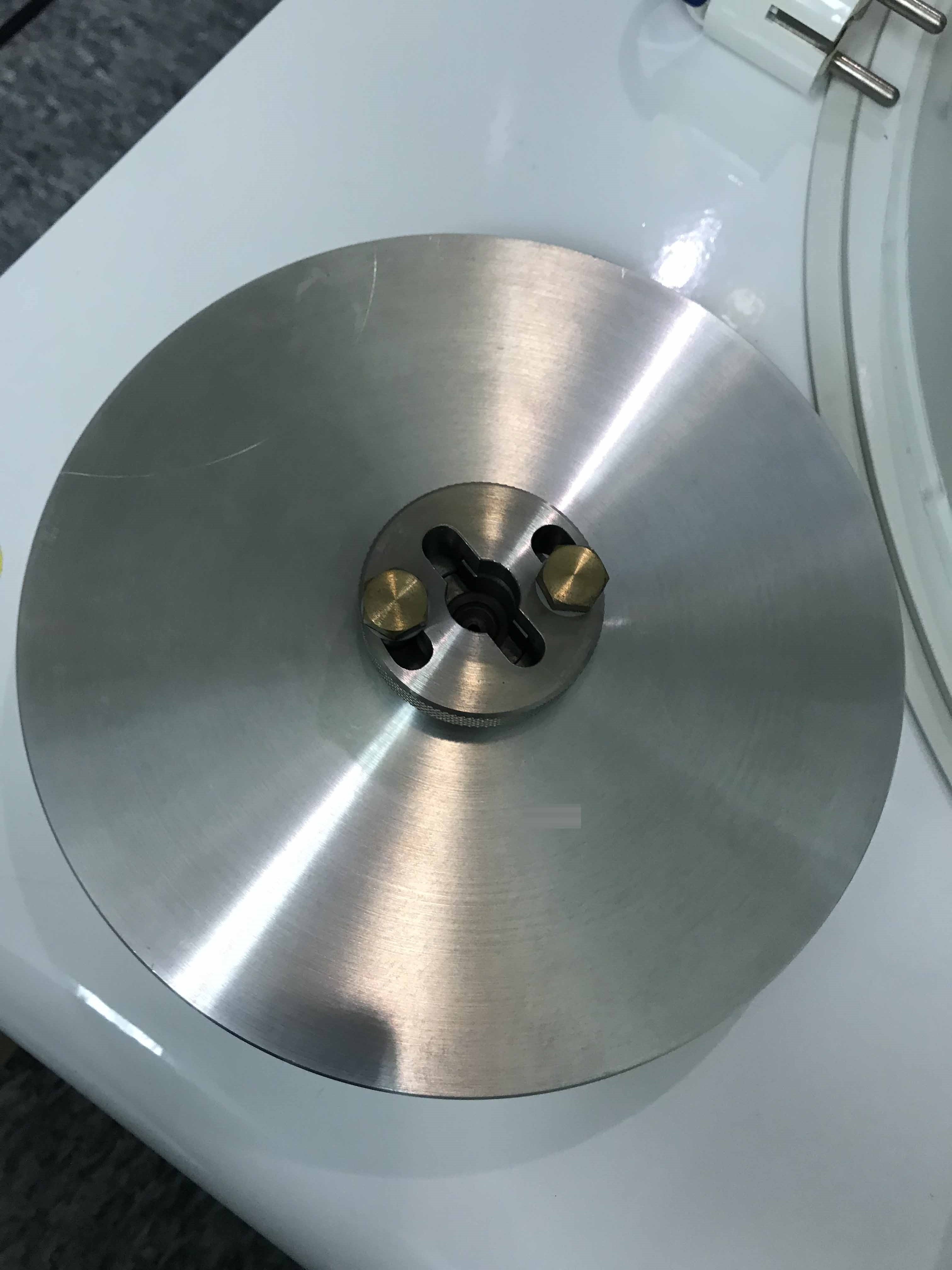

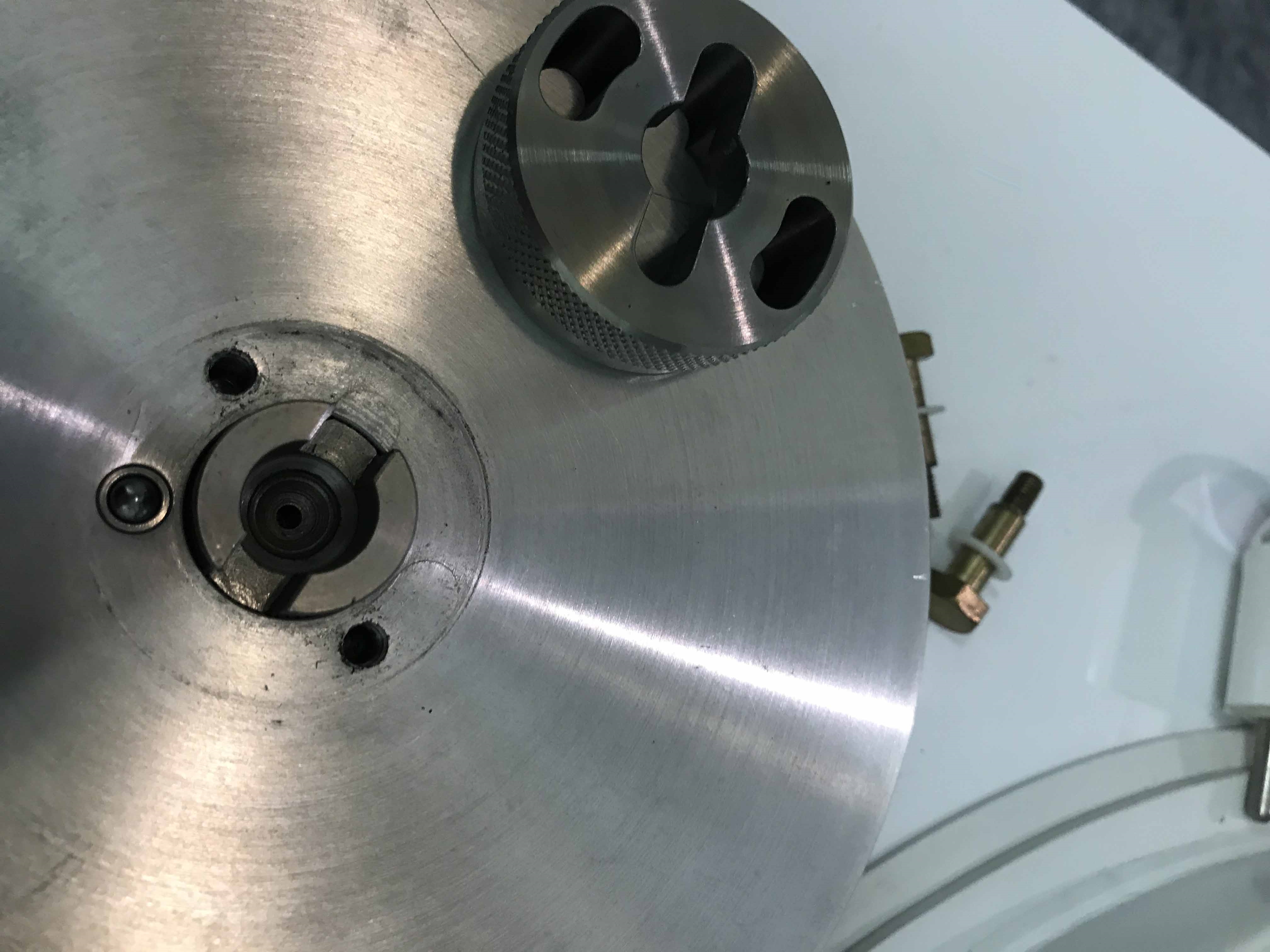

Bottom chuck: 400 mm

Top chuck: 200 mm

Base plate: 0.380 mm

Almag plate: 0.400 mm x 20 mm

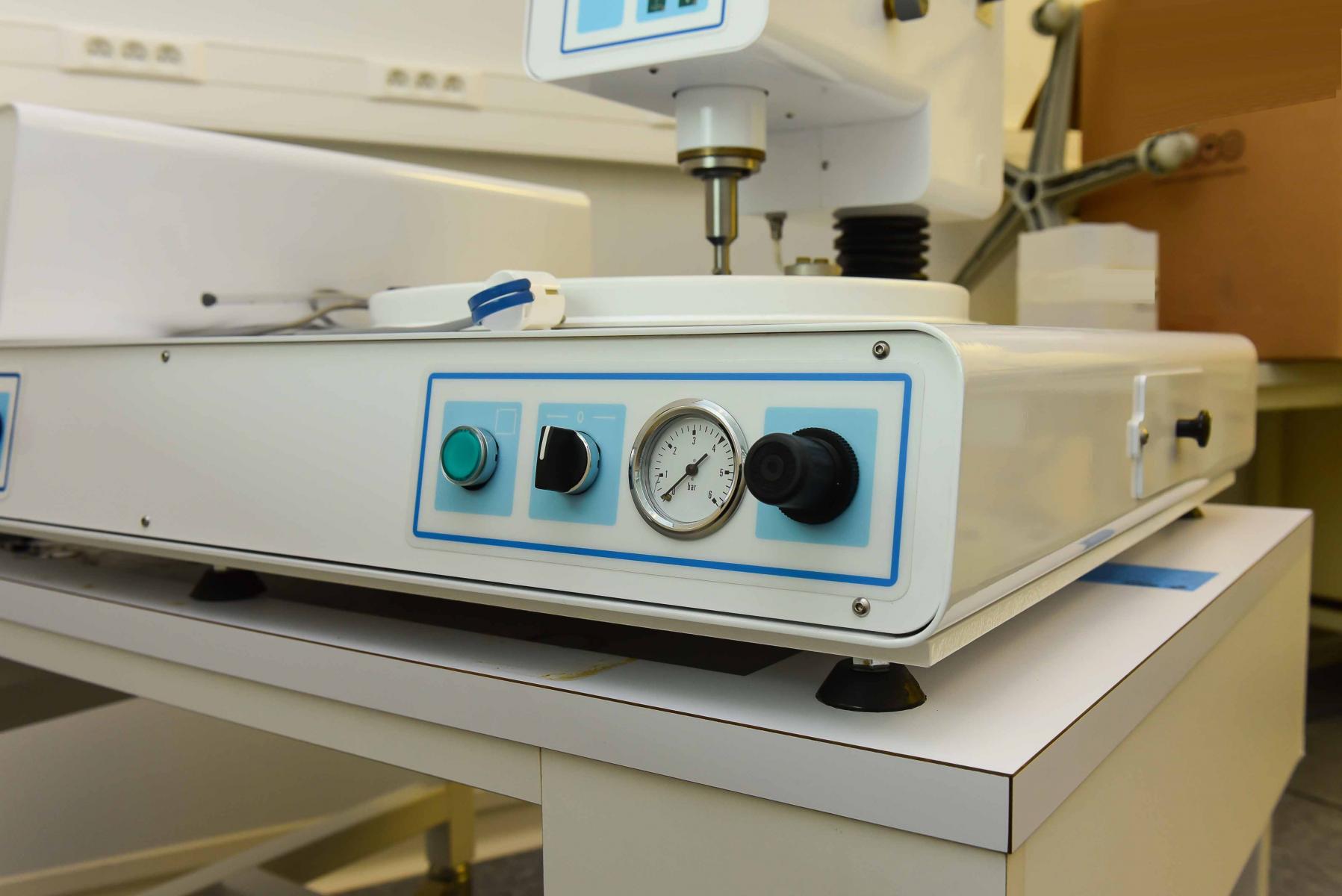

Variable speed: 30 to 300 rpm

Constant torque

Progressive acceleration

2-Pre-selected speed: 50/100 rpm

2-Direction rotations

Digital display of speeds

Touch sensitive keys with LED indicators

Frame protected against rust corrosion

Painted steel body

Large proportional bowl, tilted and removable

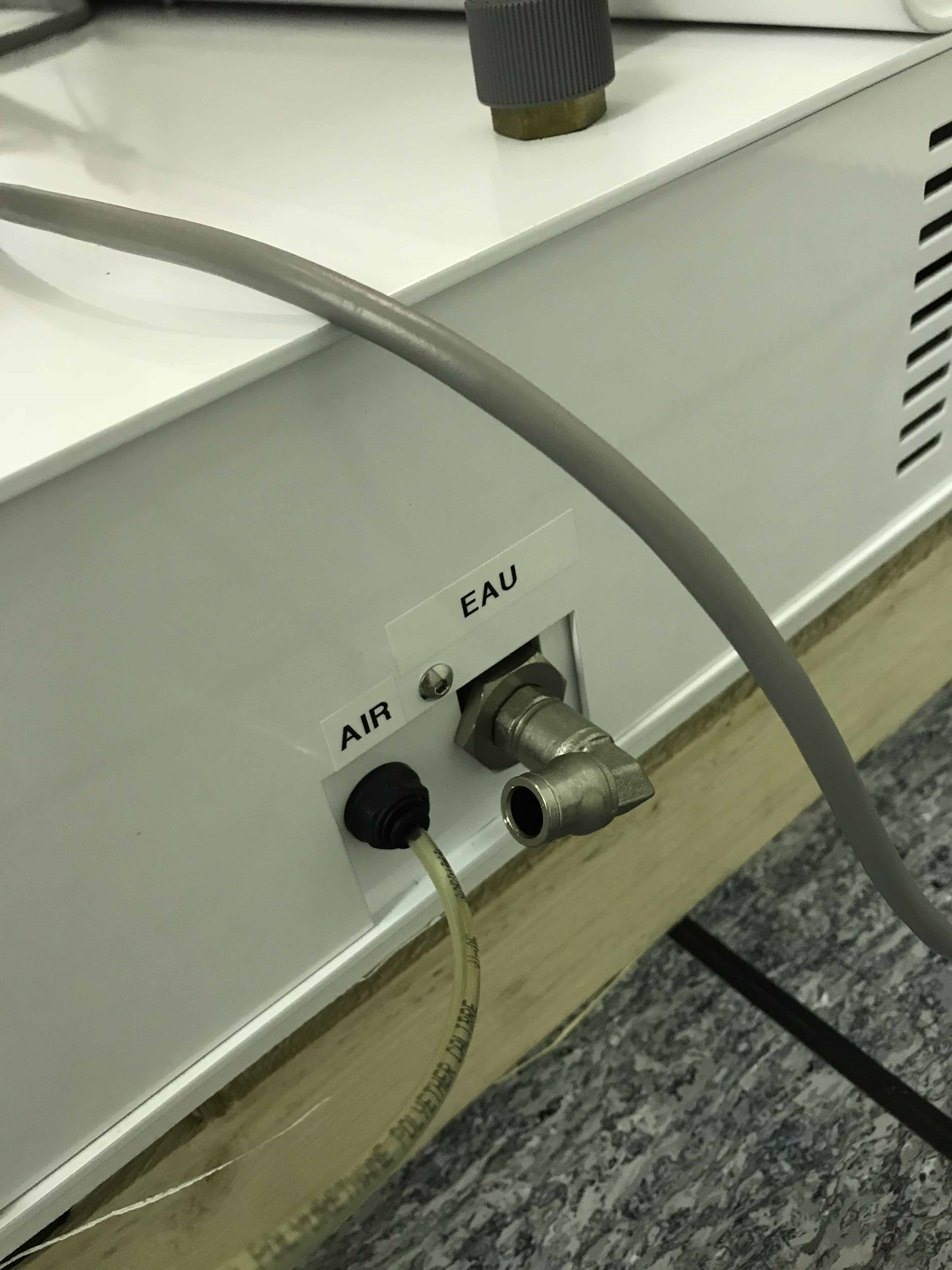

Water inlet driven by sluice gate

Multi spray water cooling

Voltage: 230 V, 1 Phase

Power: 750 Watts

PE.RE B:

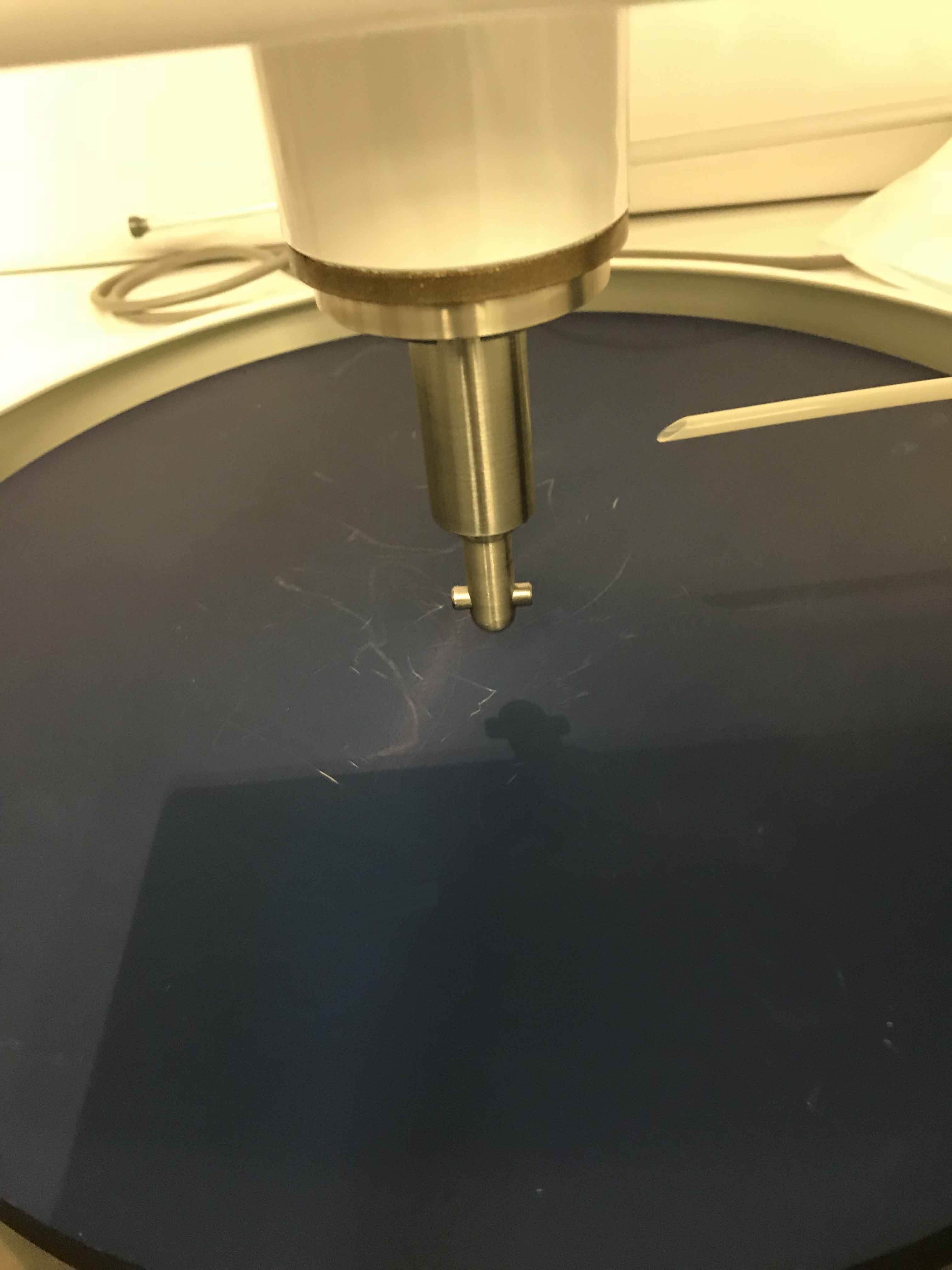

Polishing head with central pressure

Digital display of time and pressure

Low pressure loading and unloading

Touch sensitive keys

Adjustable sweep (Position, amplitude and velocity)

Tank for 150 ml of lubricant

Adjustable and driven lubricant flow

Consolidated spindle

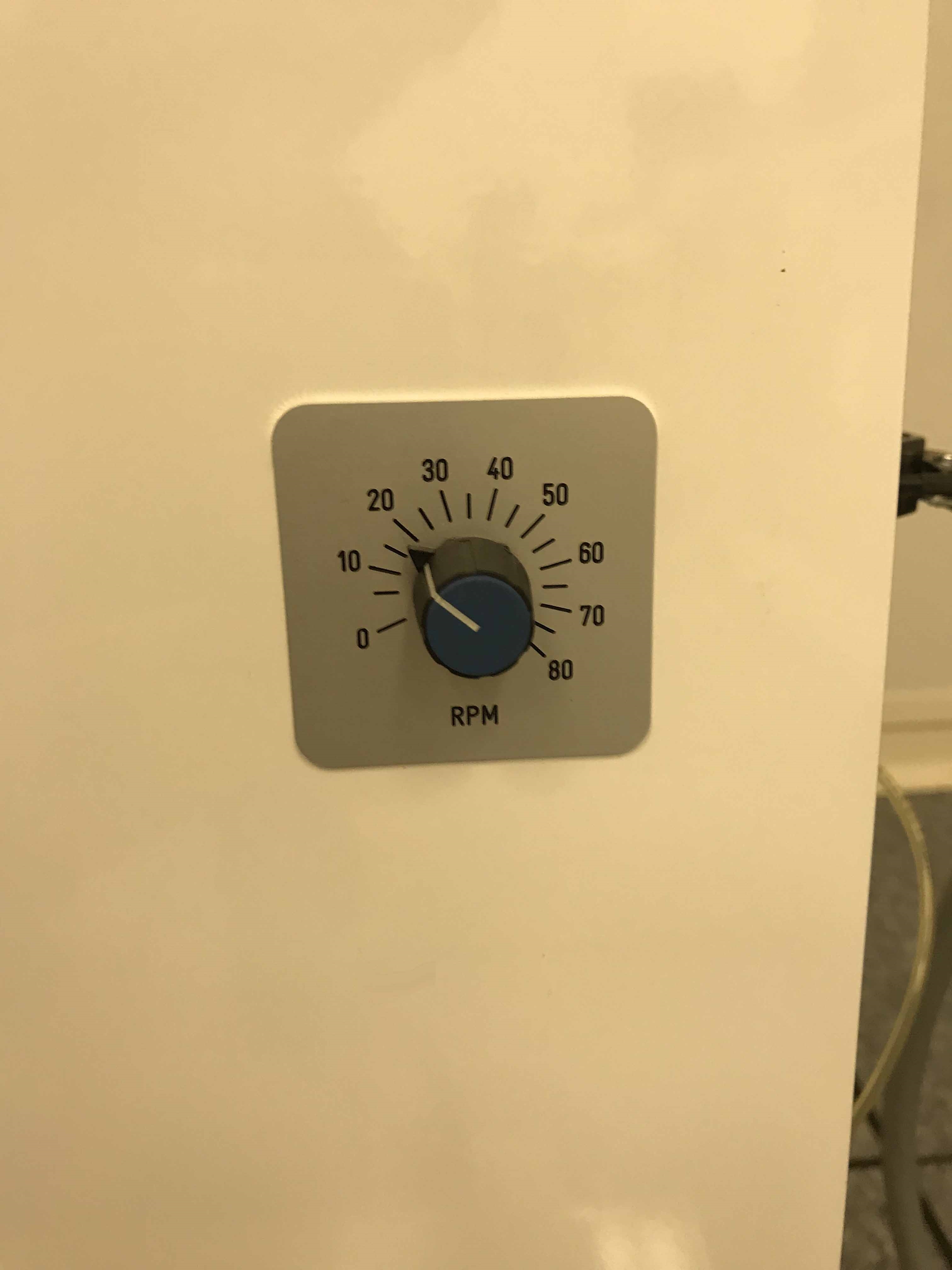

Variable speed: 20 to 80 rpm

Pneumatic pressure: Electronically from 0,5 to 40 daN

Direct reading of pressure

Voltage: 230 V, Single phase

Power: 120 Watts

2005-2006 vintage.

PRESI MECAPOL P 400 is an advanced wafer grinding, lapping and polishing equipment. It is designed to achieve the highest quality levels for wafer processing requirements. The system consists of 6 independent workstations that can be configured for various grinding, lapping, and polishing operations. In addition, each station is designed with a patented and proven industrial-grade motor controller that help to provide consistent performance. The unit utilizes a sophisticated grinding, lapping and polishing process with a unique motor and variable speed control interface. This interface ensures accurate control of the motor speed and a consistent material removal rate. The patented workstation design also allows for precise mechanical adjustments and process optimization. MECAPOL P 400 is designed with a process parameter adjustment function, making it easier for operators to monitor and adjust the machine parameters in real time. It is also equipped with a high-precision computer-controlled tool, making it possible to achieve highest-quality processing results. The asset is equipped with an automatic wafer centering model, which ensures that the wafers are consistently centered and perfectly aligned for optimal processing. The grinding disc is equipped with a patented and proven flat diamond grinding disc, that ensures accurate grinding surfaces with minimal surface deformation. The wafer lapping station offers a fully automated lapping process, ensuring that each wafer receives the same lapping treatment. The equipment is also equipped with an intelligent feedback system which monitors and engages operations according to the given parameters. With the feedback unit, operators can easily adjust operating parameters and select the optimal process for their needs. In addition to its features, PRESI MECAPOL P 400 also offers a user-friendly control interface with a clear display and touch panel. This user-friendly interface offers clear instructions and operation guides, making it easy for operators to set up the machine and achieve the desired results. MECAPOL P 400 is an ideal choice for wafer grinding, lapping and polishing applications, providing excellent results and consistent performance. With its advanced features and user-friendly controls, it is a reliable tool for both engineering professionals and laboratory researchers looking for optimal wafer processing results.

There are no reviews yet