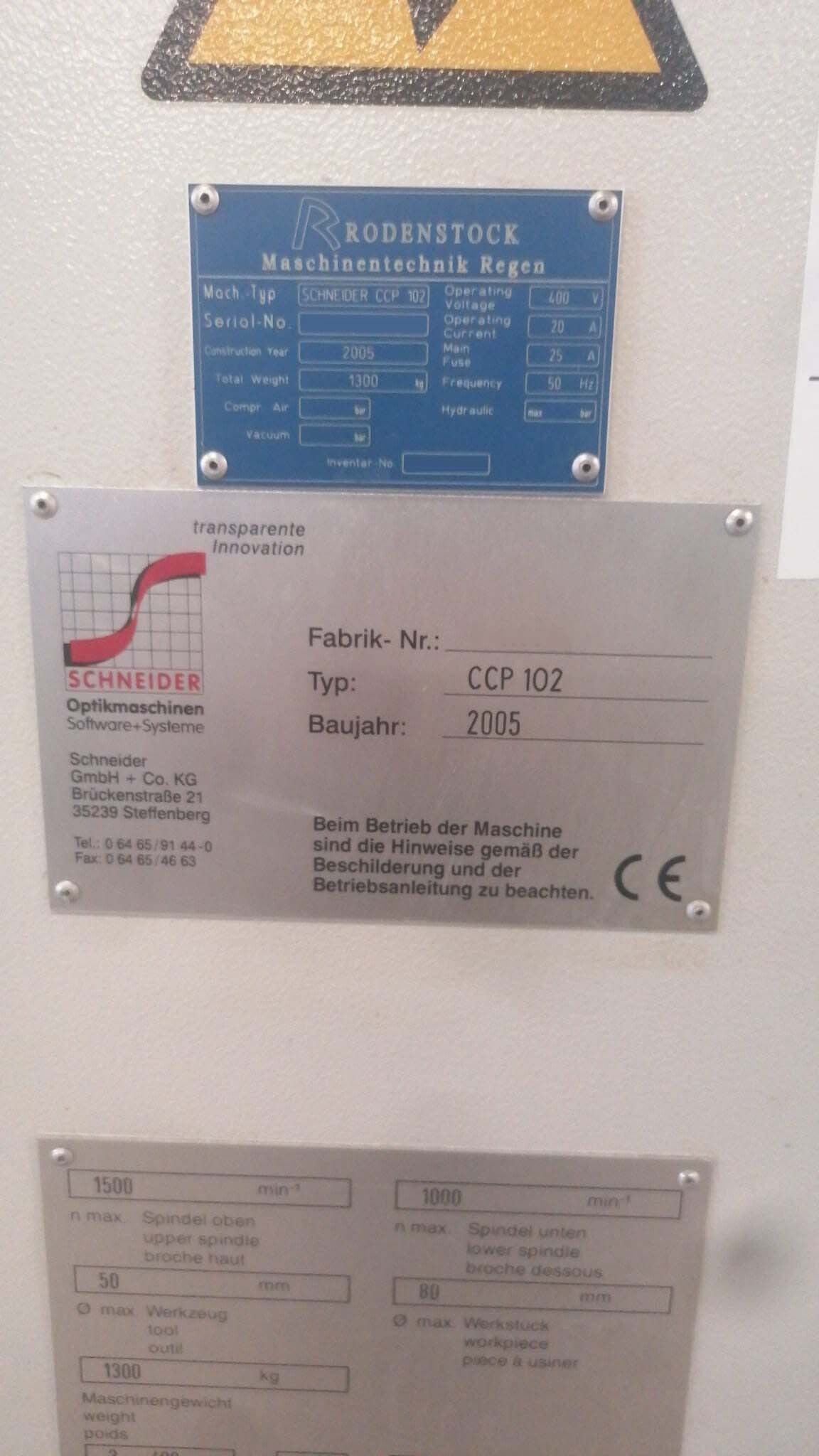

Used SCHNEIDER CCP 102 #9295054 for sale

URL successfully copied!

Tap to zoom

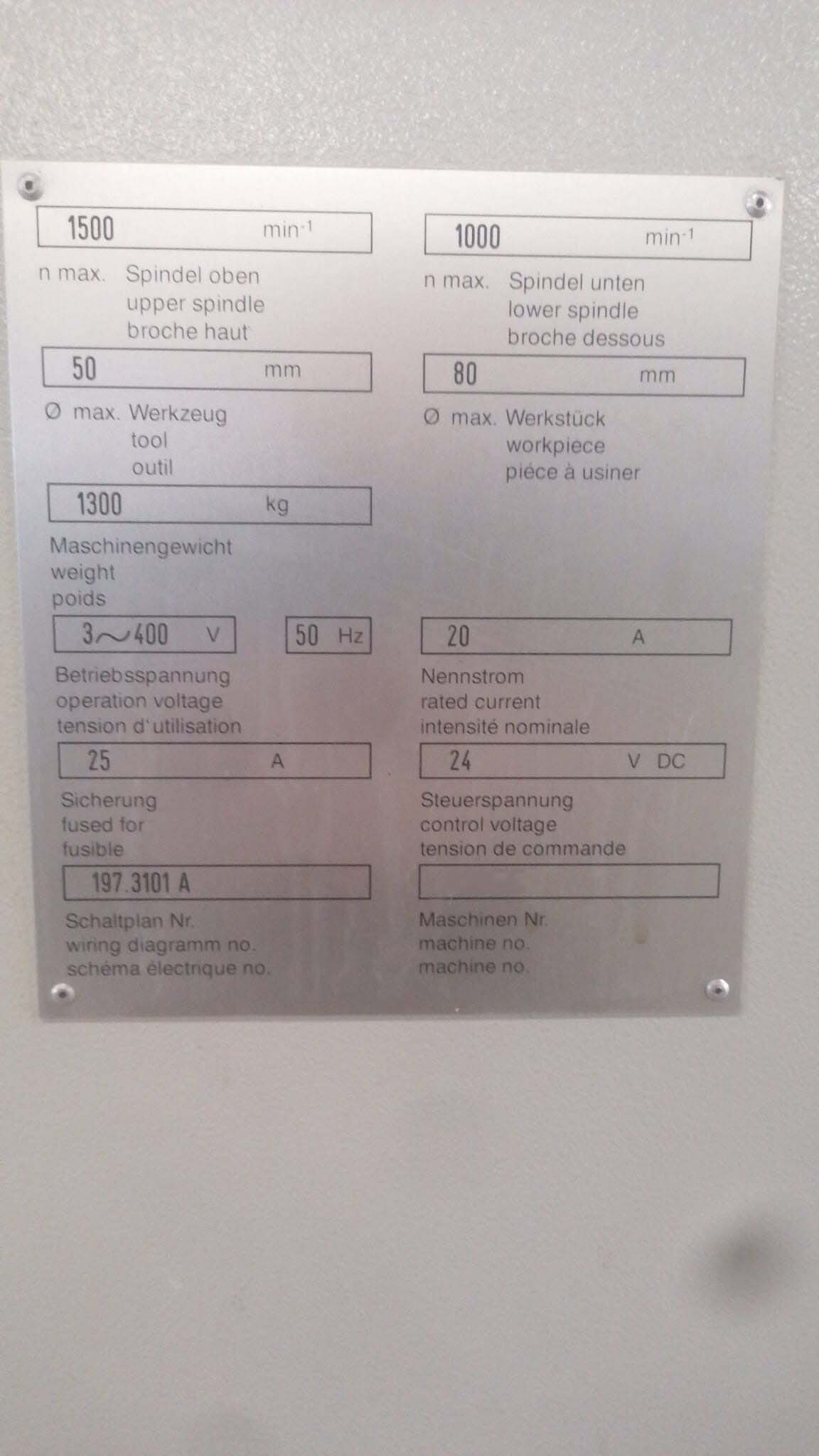

SCHNEIDER CCP 102 wafer grinding, lapping & polishing equipment is an advanced precision processing solution for semiconductor industry operations. CCP 102 is a high-performance, small footprint system designed specifically for substrate processing including back grinding, lapping, and polishing of a range of popular wafer sizes. The flexible mechanical design supports various unit combinations that are dependent on the application, while ensuring adequate processing capacities. SCHNEIDER CCP 102 utilizes a two-step mechanical back grinding process that begins with a rough grinding first step, which removes the initial layer of substrate material. The majority of the chips are cut during the first step, resulting in a uniform layer of material for lapping. The second step fine grinding process provides a smooth and flat surface ready for lapping. The advanced lapping module of CCP 102 is capable of providing a homogeneous surface finish with minimal processing times. Additionally, the utilization of urethane coated tooling, removable bonding pads, and height markers assist in process optimization. The polishing module of SCHNEIDER CCP 102 utilizes the latest in polishing technologies, including an adjustable ring platen machine for uniform compliance and spin disc tool for uniform movement. The combination of wet or dry polishing capability, in tandem with a wide variety of polishing media options, offers unparalleled process control and flexibility. It also allows for the selection of polishing parameters such as pressure, media slurry properties, and polishing time in order to precisely tune the finish of the substrates. Other aspects of CCP 102 that make this asset a great choice for precision substrate processing include its open model design, modular construction, and easy access to components that make maintenance and upgrades easy. The equipment's intuitive and user-friendly control system allows for an ease of use and process repeatability between runs. The robust mechanical design and efficient safety function also provide a safe and comfortable operation experience. In sum, SCHNEIDER CCP 102 wafer grinding, lapping & polishing unit is a truly professional and advanced precision processing solution for semiconductor industry applications. This high-performance, small footprint machine is designed for reliably, accurately and safely producing the perfect finish for your substrate materials while providing exceptional process control and flexibility.

There are no reviews yet